Abstract

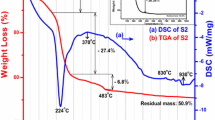

In this work we report the size-controlled synthesis of BiFeO3 nanoparticles via a soft-chemistry route. In this route, the aqueous solution of inorganic Bi and Fe salt is gelled by using acrylamide and bisacrylamide. It is demonstrated that the grain size of resulted BiFeO3 powders can be tailored by varying the ratio of acrylamide to bisacrylamide. With increase in the bisacrylamide content, the grain size decreases monotonously. By using this method, a series of BiFeO3 samples with average grain size ranging from 110 to 52 nm have been prepared. The thermal decomposition process of precursor xerogels and the formation of BiFeO3 phase are investigated by means of X-ray diffraction, thermogravimetric analysis, differential scanning calorimetry analysis, and fourier transform infrared spectroscopy (FTIR). SEM observations reveal that the prepared BiFeO3 nanoparticles are nearly spherical in shape with a narrow diameter distribution. Magnetic hysteresis loop measurement shows that the BiFeO3 nanoparticles exhibit weak ferromagnetic behavior at room temperature, and a saturation magnetization of ~1.56 emu/g is achieved for the 52 nm sample.

Similar content being viewed by others

References

Hill NA (2000) J Phys Chem B 104:6694

Fiebig M, Lottermoser Th, Fröhlich D, Goltsev AV, Pisarev RV (2002) Nature (London) 419:818

Michel C, Moreau J-M, Achenbach GD, Gerson R, James WJ (1969) Solid State Commun 7:701

Moreau J-M, Michel C, Gerson R, James WJ (1971) J Phys Chem Solids 32:1315

Tabares-Munoz C, Rivera JP, Monnier A, Schmid H (1985) Jpn J Appl Phys. Suppl 24:1051

Fischer P, Polomska M, Sosnowska I, Szymanksi M (1980) J Phys C 13:1931

Sosnowska I, Peterlin-Neumaier T, Steichele E (1982) J Phys C 15:4835

Ederer C, Spaldin NA (2005) Phys Rev B 71:060401(R)

Luo WJ, Wang DL, Peng XD, Wang FW (2009) J. Sol Gel Sci Technol 51:53

Kim SH, Jeong JW, Lee JW, Shin SC (2009) Thin Solid Films 517:2749

Xie SH, Li JY, Proksch R, Liu YM, Zhou YC, Liu YY, Ou Y, Lan LN, Qiao Y (2008) Appl Phys Lett 93:222904

Wei J, Xue DS (2008) Mater Res Bull 43:3368

Mazumder R, Devi PS, Bhattacharya D, Choudhury P, Sen A, Raja M (2007) Appl Phys Lett 91:062510

Park TJ, Papaefthymiou GC, Viescas AJ, Moodenbaugh AR, Wong SS (2007) Nano Lett 7:766

Kumar M, Yadav KL, Varma GD (2008) Mater Lett 62:1159

Chen C, Cheng JR, Yu SW, Che LJ, Meng ZY (2006) J Cryst Growth 291:135

Lu XM, Xie JM, Song YZ, Lin JM (2007) J Mater Sci 42:6824

Basu S, Pal M, Chakravorty D (2008) J Magn Magn Mater 320:3361

Cho CM, Noh JH, Cho I-S, An J-S, Hong KS, Kim JY (2008) J Am Ceram Soc 91:3753

Wang YG, Xu G, Yang LL, Ren ZH, Wei X, Weng WJ, Du PY, Shen G, Han GR (2009) Ceram Int 35:1285

Chaudhuri A, Mitra S, Mandal M, Mandal K (2010) J Alloys Compd 491:703

Joshi UA, Jang JS, Borse PH, Lee JS (2008) Appl Phys Lett 92:242106

Prado-Gonjal J, Villafuerte-Castrejo ME, Fuentes L, Mora E (2009) Mater Res Bull 44:1734

Shetty S, Palkar VR, Pinto R (2002) Pramana J Phys 58:1027

Liu ZK, Qi YJ, Lu CJ (2010) J Mater Sci Mater Electron 21:380

Das N, Majumdar R, Sen A, Maiti HS (2007) Mater Lett 61:2100

Farhadi S, Zaidi M (2009) J Mol Catal A Chem 299:18

Ghosh S, Dasgupta S, Sen A, Maiti HS (2005) Mater Res Bull 40:2073

Selbach SM, Tybell T, Einarsrud M-A, Grande T (2007) Chem Mater 19:6478

Ghosh S, Dasgupta S, Sen A, Maiti HS (2005) J Am Ceram Soc 88:1349

Xu J-H, Ke H, Jia D-C, Wang W, Zhou Y (2008) J Alloys Compd 472:473

Xian T, Yang H, Shen X, Jiang JL, Wei ZQ, Feng WJ (2009) J Alloys Compd 480:889

Kang YQ, Cao MS, Yuan J, Shi XL (2009) Mater Lett 63:1344

Jia DC, Xu JH, Ke H, Wang W, Zhou Y (2009) J Eur Ceram Soc 29:3099

Yang H, Cao ZE, Shen X, Jiang JL, Wei ZQ, Dai JF, Feng WJ (2009) Mater Lett 63:655

Yang H, Cao ZE, Shen X, Xian T, Feng WJ, Jiang JL, Feng YC, Wei ZQ, Dai JF (2009) J Appl Phys 106:104317

Subba Rao GV, Rao CNR, Ferraro JR (1970) Appl Spectrosc 24:436

Kaczmarek W, Graja A (1975) Solid State Commun 17:851

Voll D, Beran A, Schneider H (2006) Phys Chem Minerals 33:623

Kumar MM, Palkar VR, Srinivas K, Suryanarayana SV (2000) Appl Phys Lett 76:2764

Klug MP, Alexander LE (1974) X-ray diffraction procedure for polycrystalline and amorphous materials. Wiley, New York, p 634

Rüchel R, Steere RL, Erbe EF (1978) J Chromatogr 166:563

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 50962009), the key Project of Chinese Ministry of Education (Grant No. 209130) and the Natural Science Foundation of Gansu Province (Grant No. 1010RJZA041).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, H., Xian, T., Wei, Z.Q. et al. Size-controlled synthesis of BiFeO3 nanoparticles by a soft-chemistry route. J Sol-Gel Sci Technol 58, 238–243 (2011). https://doi.org/10.1007/s10971-010-2383-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-010-2383-6