Abstract

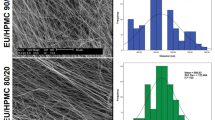

Elastomer electrospun fibers are suitable for biomedical applications due to more processability. Designing elastomer polymeric fibers with outstanding remedial effects has great practical importance in the healthcare system. For this purpose, we blended Propolis Ethanolic Extract (PEE) with poly-ε-caprolactone (PCL) and prepared elastomeric electrospun mats. We then characterized and evaluated these mats as wound dressing and Guided Tissue Regeneration (GTR) membranes. In vitro propolis release, surface hydrophilicity, degradation, and tensile testing were studied. In addition, cellular studies for biocompatibility of the mats, proliferation and migration effects, and also antibacterial and antifungal effects of the mats were assessed. Furthermore, the mats were practiced in an induced-wound rat model to study in vivo wound dressing efficiency and to perform histopathological investigation. The results indicated that the PEE-loaded mats with parallel fiber orientation exhibited 482 ± 38.89% tensile strain and those with random fiber orientation showed 144.67 ± 23.36% tensile strain. These mats showed a faster degradation rate and more hydrophilicity than the PCL mats. Moreover, the antibacterial study indicated that the PEE-loaded mats were effective against Escherichia coli, Staphylococcus aureus bacteria, and Candida albicans- an opportunistic pathogenic fungus. The PEE-loaded mats also indicated that a faster and dose-dependent migration efficacy than the control and respective PCL mats. In vivo experiments confirmed the PEE-loaded mats significantly accelerated the wound healing rate. Taken together, the elastomeric PEE-PCL mats with, good mechanical properties, and accelerated wound dressing ability offer an appropriate promise as wound dressing and GTR membranes.

Similar content being viewed by others

References

Sahoo S, Ghosh P, Banerjee S, De P (2021) Recent advances in biomedical applications of cholic acid-based macromolecules. ACS Applied Polymer Materials 3(4):1687–1706

Das P, Jana NR (2021) Biomedical Applications of Functional Polyaspartamide-Based Materials. ACS Applied Polymer Materials 3(10):4791–4811

Joseph B, Augustine R, Kalarikkal N, Thomas S, Seantier B, Grohens Y (2019) Recent advances in electrospun polycaprolactone based scaffolds for wound healing and skin bioengineering applications. Materials Today Communications 19:319–335

Ambekar RS, Kandasubramanian B (2019) Advancements in nanofibers for wound dressing: A review. Eur Polymer J 117:304–336

Murphy KG, Gunsolley JC (2003) Guided tissue regeneration for the treatment of periodontal intrabony and furcation defects. A systematic review Annals of periodontology 8(1):266–302

Zhang L, Dong Y, Zhang N, Shi J, Zhang X, Qi C, Midgley AC, Wang S (2020) Potentials of sandwich-like chitosan/polycaprolactone/gelatin scaffolds for guided tissue regeneration membrane. Mater Sci Eng, C 109:110618

Kurakula M, Koteswara Rao GSN (2020) Moving polyvinyl pyrrolidone electrospun nanofibers and bioprinted scaffolds toward multidisciplinary biomedical applications. Euro Polym J 136:109919

Xue J, He M, Liang Y, Crawford A, Coates P, Chen D, Shi R, Zhang L (2014) Fabrication and evaluation of electrospun PCL–gelatin micro-/nanofiber membranes for anti-infective GTR implants. J Mater Chem B 2(39):6867–6877

Calori IR, Braga G, de Jesus PDCC, Bi H, Tedesco AC (2020) Polymer scaffolds as drug delivery systems. Euro Polym J 129:109621

Cho YS, Quan M, Kang N-U, Jeong H-J, Hong MW, Kim YY, Cho Y-S (2020) Strategy for enhancing mechanical properties and bone regeneration of 3D polycaprolactone kagome scaffold: Nano hydroxyapatite composite and its exposure. Eur Polymer J 134:109814

Hege CS, Siegel-Axel D, Kohler K, Delorme N, Le Houerou V, Schiller SM, Dolderer JH (2020) Biopolymer Systems in Soft Tissue Engineering: Cell Compatibility and Effect Studies Including Material, Catalyst, and Surface Properties. ACS Applied Polymer Materials 2(8):3251–3258

Maccaferri E, Mazzocchetti L, Benelli T, Brugo TM, Zucchelli A, Giorgini L (2020) Rubbery nanofibers by co-electrospinning of almost immiscible NBR and PCL blends. Mater Des 186:108210

Liang J, Chen H, Guo Z, Dijkstra P, Grijpma D, Poot A (2021) Tough fibrous mats prepared by electrospinning mixtures of methacrylated poly (trimethylene carbonate) and methacrylated gelatin. Eur Polymer J 152:110471

Ekram B, Abd El-Hady BM, El-Kady AM, Amr SM, Gabr H, Waly AI, Guirguis OW (2019) Enhancing the stability, hydrophilicity, mechanical and biological properties of electrospun polycaprolactone in formic acid/acetic acid solvent system. Fibers Polym 20(4):715–724

Burdock GA (1998) Review of the biological properties and toxicity of bee propolis (propolis). Food Chem Toxicol 36(4):347–363

Park YK, Alencar SM, Aguiar CL (2002) Botanical origin and chemical composition of Brazilian propolis. J Agric Food Chem 50(9):2502–2506

Pietta PG, Gardana C, Pietta AM (2002) Analytical methods for quality control of propolis. Fitoterapia 73:S7–S20

Pahlevanneshan Z, Deypour M, Kefayat A, Rafienia M, Sajkiewicz P, Esmaeely Neisiany R, Enayati MS (2021) Polyurethane-Nanolignin Composite Foam Coated with Propolis as a Platform for Wound Dressing: Synthesis and Characterization. Polymers 13(18):3191

Ceylan S (2021) Propolis loaded and genipin-crosslinked PVA/chitosan membranes; characterization properties and cytocompatibility/genotoxicity response for wound dressing applications. Int J Biol Macromol 181:1196–1206

Cesar PHS, Natarelli CVL, Oliveira JED, Andrade PA, dos Santos TL, Marcussi S (2021) Development and characterization of a poly (vinyl alcohol) and sodium alginate blend foam for wound dressing loaded with propolis and all‐trans retinoic acid. J Appl Polym Sci 138(21):50480

Wagh VD (2013) Propolis: a wonder bees product and its pharmacological potentials. Advances in pharmacological sciences

Blainski A, Lopes GC, De Mello JCP (2013) Application and analysis of the Folin Ciocalteu method for the determination of the total phenolic content from Limonium Brasiliense L. Molecules 18(6):6852–6865

Andrews JM (2001) Determination of minimum inhibitory concentrations. J Antimicrob Chemotherap 48(suppl_1):5–16

Wayne PA (2011) Clinical and laboratory standards institute. Performance standards for antimicrobial susceptibility testing

Augustine R, Nethi SK, Kalarikkal N, Thomas S, Patra CR (2017) Electrospun polycaprolactone (PCL) scaffolds embedded with europium hydroxide nanorods (EHNs) with enhanced vascularization and cell proliferation for tissue engineering applications. J Mater Chem B 5(24):4660–4672

Ghosal K, Chandra A, Praveen G, Snigdha S, Roy S, Agatemor C, Thomas S, Provaznik I (2018) Electrospinning over solvent casting: tuning of mechanical properties of membranes. Sci Rep 8(1):1–9

Baji A, Mai Y-W, Wong S-C, Abtahi M, Chen P (2010) Electrospinning of polymer nanofibers: Effects on oriented morphology, structures and tensile properties. Compos Sci Technol 70(5):703–718

Thomas V, Jose MV, Chowdhury S, Sullivan JF, Dean DR, Vohra YK (2006) Mechano-morphological studies of aligned nanofibrous scaffolds of polycaprolactone fabricated by electrospinning. J Biomater Sci Polym Ed 17(9):969–984

Sutjarittangtham K, Sanpa S, Tunkasiri T, Chantawannakul P, Intatha U, Eitssayeam S (2014) Bactericidal effects of propolis/polylactic acid (PLA) nanofibres obtained via electrospinning. J Apic Res 53(1):109–115

Zhu Y, Shah NH, Malick AW, Infeld MH, McGinity JW (2002) Solid-state plasticization of an acrylic polymer with chlorpheniramine maleate and triethyl citrate. Int J Pharm 241(2):301–310

Rabek CL, Stelle RV, Dziubla TD, Puleo DA (2014) The effect of plasticizers on the erosion and mechanical properties of polymeric films. J Biomater Appl 28(5):779–789

Lim CT, Tan EPS, Ng SY (2008) Effects of crystalline morphology on the tensile properties of electrospun polymer nanofibers. Appl Phys Lett 92(14):141908

Ahmed MK, Mansour SF, Al-Wafi R, El-dek SI, Uskoković V (2019) Tuning the mechanical, microstructural, and cell adhesion properties of electrospun ε-polycaprolactone microfibers by doping selenium-containing carbonated hydroxyapatite as a reinforcing agent with magnesium ions. J Mater Sci 54(23):14524–14544

Gomes SR, Rodrigues G, Martins GG, Roberto MA, Mafra M, Henriques CMR, Silva JC (2015) In vitro and in vivo evaluation of electrospun nanofibers of PCL, chitosan and gelatin: A comparative study. Mater Sci Eng C 46:348–358

Eskandarinia A, Kefayat A, Agheb M, Rafienia M, Baghbadorani MA, Navid S, Ebrahimpour K, Khodabakhshi D, Ghahremani F (2020) A Novel Bilayer Wound Dressing Composed of a Dense Polyurethane/Propolis Membrane and a Biodegradable Polycaprolactone/Gelatin Nanofibrous Scaffold. Sci Rep 10(1):1–15

Sutjarittangtham K, Tunkasiri T, Chantawannakul P, Intatha U, Eitssayeam S (2015) Mechanically improved antibacterial polycaprolactone/propolis electrospun fiber mat by adding bacterial nanocellulose. J Comput Theor Nanosci 12(5):798–803

Shahrifi BH, Mohammadi M, Manoochehri M, Atashi A (2020) Mechanical and biological properties of polycaprolactone/fibrin nanocomposite adhesive produced by electrospinning method. Bull Mater Sci 43(1):1–8

Croisier F, Duwez AS, Jérôme C, Léonard AF, Van Der Werf KO, Dijkstra PJ, Bennink ML (2012) Mechanical testing of electrospun PCL fibers. Acta Biomater 8(1):218–224

Yao R, He J, Meng G, Jiang B, Wu F (2016) Electrospun PCL/Gelatin composite fibrous scaffolds: mechanical properties and cellular responses. J Biomater Sci Polym Ed 27(9):824–838

Heydari Z, Mohebbi-Kalhori D, Afarani MS (2017) Engineered electrospun polycaprolactone (PCL)/octacalcium phosphate (OCP) scaffold for bone tissue engineering. Mater Sci Eng C 81:127–132

Hivechi A, Bahrami SH, Siegel RA (2019) Drug release and biodegradability of electrospun cellulose nanocrystal reinforced polycaprolactone. Mater Sci Eng C 94:929–937

Samani DA, Doostmohammadi A, Nilforoushan MR, Nazari H (2019) Electrospun Polycaprolactone/Graphene/Baghdadite Composite Nanofibres with Improved Mechanical and Biological Properties. Fibers Polym 20(5):982–990

Nazeer MA, Yilgor E, Yilgor I (2019) Electrospun polycaprolactone/silk fibroin nanofibrous bioactive scaffolds for tissue engineering applications. Polymer 168:86–94

Tohidlou H, Shafiei SS, Abbasi S, Asadi-Eydivand M, Fathi-Roudsari M (2019) Amine-functionalized single-walled carbon nanotube/polycaprolactone electrospun scaffold for bone tissue engineering: in vitro study. Fibers Polym 20(9):1869–1882

Martinez-Diaz S, Garcia-Giralt N, Lebourg M, Gómez-Tejedor J-A, Vila G, Caceres E, Benito P, Monleon Pradas M, Nogues X, Gomez Ribelles JL (2010) In vivo evaluation of 3-dimensional polycaprolactone scaffolds for cartilage repair in rabbits. Am J Sports Med 38(3):509–519

Schilp S, Kueller A, Rosenhahn A, Grunze M, Pettitt ME, Callow ME, Callow JA (2007) Settlement and adhesion of algal cells to hexa (ethylene glycol)-containing self-assembled monolayers with systematically changed wetting properties. Biointerphases 2(4):143–150

Wei Q, Becherer T, Angioletti-Uberti S, Dzubiella J, Wischke C, Neffe AT, Lendlein A, Ballauff M, Haag R (2014) Protein interactions with polymer coatings and biomaterials. Angew Chem Int Ed 53(31):8004–8031

Ma S, Wang Z, Guo Y, Wang P, Yang Z, Han L, Sun J, Xia Y (2019) Enhanced osteoinduction of electrospun scaffolds with assemblies of hematite nanoparticles as a bioactive interface. Int J Nanomed 14:1051

Kasalkova NS, Slepicka P, Kolska Z, Svorcik V (2015) Wettability and other surface properties of modified polymers. Wetting and Wettability 12:323–356

Silva JC, Rodrigues S, Feás X, Estevinho LM (2012) Antimicrobial activity, phenolic profile and role in the inflammation of propolis. Food Chem Toxicol 50(5):1790–1795

Bartnikowski M, Dargaville TR, Ivanovski S, Hutmacher DW (2019) Degradation mechanisms of polycaprolactone in the context of chemistry, geometry and environment. Prog Polym Sci 96:1–20

Göpferich A (1996) Mechanisms of polymer degradation and erosion. Biomaterials 17(2):103–114

Tamada JA, Langer R (1993) Erosion kinetics of hydrolytically degradable polymers. Proc Natl Acad Sci 90(2):552–556

Visan AI, Popescu-Pelin G, Gherasim O, Mihailescu A, Socol M, Zgura I, Chiritoiu M, Elena Sima L, Antohe F, Ivan L (2020) Long-term evaluation of dip-coated pcl-blend-peg coatings in simulated conditions. Polymers 12(3):717

Kim HW, Lee EJ, Jun IK, Kim HE, Knowles JC (2005) Degradation and drug release of phosphate glass/polycaprolactone biological composites for hard-tissue regeneration. J Biomed Mater Res Part B: Appl Biomater: An Official J Soc Biomater, Japanese Soc Biomater, Australian Soc Biomater Korean Soc Biomater 75(1):34–41

Woodruff MA, Hutmacher DW (2010) The return of a forgotten polymer—Polycaprolactone in the 21st century. Prog Polym Sci 35(10):1217–1256

Von Burkersroda F, Schedl L, Göpferich A (2002) Why degradable polymers undergo surface erosion or bulk erosion. Biomaterials 23(21):4221–4231

Loh XJ (2013) The effect of pH on the hydrolytic degradation of poly (ε-caprolactone)-block-poly (ethylene glycol) copolymers. J Appl Polym Sci 127(3):2046–2056

Martinotti S, Ranzato E (2015) Propolis: a new frontier for wound healing? Burns & trauma 3(1):1–7

Alberti TB, Coelho DS, de Prá M, Maraschin M, Veleirinho B (2020) Electrospun PVA nanoscaffolds associated with propolis nanoparticles with wound healing activity. J Mater Sci 55(23):9712–9727

Stojko M, Włodarczyk J, Sobota M, Karpeta-Jarząbek P, Pastusiak M, Janeczek H, Dobrzyński P, Starczynowska G, Orchel A, Stojko J (2020) Biodegradable electrospun nonwovens releasing propolis as a promising dressing material for burn wound treatment. Pharmaceutics 12(9):883

Jacob A, Parolia A, Pau A, Amalraj FD (2015) The effects of Malaysian propolis and Brazilian red propolis on connective tissue fibroblasts in the wound healing process. BMC Complement Altern Med 15(1):1–10

Arunkumar P, Dougherty JA, Weist J, Kumar N, Angelos MG, Powell HM, Khan M (2019) Sustained release of basic fibroblast growth factor (bFGF) encapsulated polycaprolactone (PCL) microspheres promote angiogenesis in vivo. Nanomaterials 9(7):1037

Liu H, Zhu X, Guo H, Huang H, Huang S, Huang S, Xue W, Zhu P, Guo R (2020) Nitric oxide released injectable hydrogel combined with synergistic photothermal therapy for antibacterial and accelerated wound healing. Appl Mater Today 20:100781

Kalaycıoğlu Z, Kahya N, Adımcılar V, Kaygusuz H, Torlak E, Akın-Evingür G, Erim FB (2020) Antibacterial nano cerium oxide/chitosan/cellulose acetate composite films as potential wound dressing. Eur Polymer J 133:109777

Przybyłek I, Karpiński TM (2019) Antibacterial properties of propolis. Molecules 24(11):2047

Dickinson LE, Gerecht S (2016) Engineered biopolymeric scaffolds for chronic wound healing. Front Physiol 7:341

De Almeida EC, Menezes H (2002) Anti-inflammatory activity of propolis extracts: a review. J Venom Anim Toxins 8:191–212

Acknowledgements

This work was financially supported by the Kermanshah Medical Science University (Project ID: 97659). The authors thank the Razi University and the Kermanshah Medical Science University for support of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mohamadinooripoor, R., Kashanian, S., Moradipour, P. et al. Novel elastomeric fibrous composites of poly-ε-caprolactone/propolis and their evaluation for biomedical applications. J Polym Res 29, 313 (2022). https://doi.org/10.1007/s10965-022-03165-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03165-5