Abstract

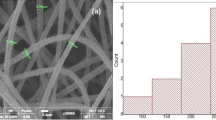

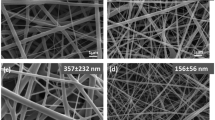

In the present study, the influence of electrospinning parameters on poly(lactic acid) (PLA) nanofiber production and antimicrobial attitude of drug blending were investigated. The PLA concentrations (5 to 12% wt/v) were determined with solvent ratio variations of a triple solvent system (chloroform (CHL), dimethylformamide (DMF) and tetrahydrofuran (THF)). Flow rates were varied from 0.5 to 1 mL/h, while voltages were changed from 10 to 15 kV, and 10 kV voltage and 0.5 mL/h flow rate were selected as optimum electrospinning conditions. According to morphological investigations via scanning electron microscopy, the average PLA fiber diameters varied from 303 to 405 nm, for 5 and 8% wt/v PLA concentrations, respectively. The drug (ceftriaxone disodium) was blended into these concentrations and electrospun. Drug addition reduced the fiber diameters, and at 8% wt/v drug blended PLA concentrations homogeneous fiber distribution was obtained. Additionally, the antimicrobial attitude of drug blended PLA nanofibers was analyzed by using agar disc diffusion method and antimicrobial activity against Escherichia coli, and Listeria monocytogenes were observed.

Graphical abstract

Similar content being viewed by others

References

Hu X, Liu S, Zhou G, Huang Y, Xie Z, Jing X (2014) Electrospinning of polymeric nanofibers for drug delivery applications. J Control Release 185:12–21

Chen C, Lv G, Pan C, Song M, Wu C, Guo D, Wang X, Chen B, Gu Z (2007) Poly(lactic acid) (PLA) based nanocomposites - a novel way of drug-releasing. Biomed Mater 2:L1–L4. https://doi.org/10.1088/1748-6041/2/4/L01

Bhardwaj N, Kundu SC (2010) Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv 28:325–347

Song K, Wu Q, Qi Y, Kärki T (2017) Electrospun nanofibers with antimicrobial properties. In: Electrospun Nanofibers. Elsevier, pp 551–569.

Scaffaro R, Lopresti F, D’Arrigo M, Marino A, Nostro A (2018) Efficacy of poly(lactic acid)/carvacrol electrospun membranes against Staphylococcus aureus and Candida albicans in single and mixed cultures. Appl Microbiol Biotechnol 102:4171–4181. https://doi.org/10.1007/s00253-018-8879-7

Islam MS, Ang BC, Andriyana A, Afifi AM (2019) A review on fabrication of nanofibers via electrospinning and their applications. SN Appl Sci 1. https://doi.org/10.1007/s42452-019-1288-4

Li J, Feng X, Shi J, Liu T, Ding J (2018) Porous Polylactide film plus atorvastatin-loaded Thermogel as an efficient device for peritoneal adhesion prevention. ACS Omega 3:2715–2723. https://doi.org/10.1021/acsomega.8b00090

Wyrwa R, Otto K, Voigt S, Enkelmann A, Schnabelrauch M, Neubert T, Schneider G (2018) Electrospun mucosal wound dressings containing styptics for bleeding control. Mater Sci Eng C 93:419–428. https://doi.org/10.1016/j.msec.2018.07.066

Luo SH, Wu YC, Cao L, Wang QF, Chen SX, Hao ZF, Jing L, Wang ZY (2017) One-pot preparation of polylactic acid-ibuprofen conjugates and their performance characterization. Polym Chem 8:7009–7016. https://doi.org/10.1039/c7py01213f

Kenawy ER, Bowlin GL, Mansfield K, Layman J, Simpson DG, Sanders EH, Wnek GE (2002) Release of tetracycline hydrochloride from electrospun poly(ethylene-co-vinylacetate), poly(lactic acid), and a blend. J Control Release 81:57–64. https://doi.org/10.1016/S0168-3659(02)00041-X

Kenawy ER, Abdel-Hay FI, El-Newehy MH, Wnek GE (2009) Processing of polymer nanofibers through electrospinning as drug delivery systems. Mater Chem Phys 113:296–302. https://doi.org/10.1016/j.matchemphys.2008.07.081

Pillay V, Dott C, Choonara YE, et al (2013) A review of the effect of processing variables on the fabrication of electrospun nanofibers for drug delivery applications. J Nanomater 2013:1–22. https://doi.org/10.1155/2013/789289

Zhang Q, Li Y, Lin ZYW et al (2017) Electrospun polymeric micro/nanofibrous scaffolds for long-term drug release and their biomedical applications. Drug Discov Today 22:1351–1366

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 63:2223–2253. https://doi.org/10.1016/S0266-3538(03)00178-7

Barkoula NM, Garkhail SK, Peijs T (2010) Effect of compounding and injection molding on the mechanical properties of flax fiber polypropylene composites. J Reinf Plast Compos 29:1366–1385. https://doi.org/10.1177/0731684409104465

Kaialy W, Emami P, Asare-Addo K, Shojaee S, Nokhodchi A (2014) Psyllium: a promising polymer for sustained release formulations in combination with HPMC polymers. Pharm Dev Technol 19:269–277. https://doi.org/10.3109/10837450.2013.775156

Bhattarai RS, Bachu RD, Boddu SHS, Bhaduri S (2019) Biomedical applications of electrospun nanofibers: drug and nanoparticle delivery. Pharmaceutics 11, 5:1–30. https://doi.org/10.3390/pharmaceutics11010005

Zeng J, Xu X, Chen X, Liang Q, Bian X, Yang L, Jing X (2003) Biodegradable electrospun fibers for drug delivery. J Control Release 92:227–231. https://doi.org/10.1016/S0168-3659(03)00372-9

Zeng J, Yang L, Liang Q, Zhang X, Guan H, Xu X, Chen X, Jing X (2005) Influence of the drug compatibility with polymer solution on the release kinetics of electrospun fiber formulation. J Control Release 105:43–51. https://doi.org/10.1016/j.jconrel.2005.02.024

Kim K, Luu YK, Chang C, Fang D, Hsiao BS, Chu B, Hadjiargyrou M (2004) Incorporation and controlled release of a hydrophilic antibiotic using poly(lactide-co-glycolide)-based electrospun nanofibrous scaffolds. J Control Release 98:47–56. https://doi.org/10.1016/j.jconrel.2004.04.009

Haider A, Haider S, Kang IK (2018) A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J, Chem

Herrero-Herrero M, Gómez-Tejedor JA, Vallés-Lluch A (2018) PLA/PCL electrospun membranes of tailored fibres diameter as drug delivery systems. Eur Polym J 99:445–455. https://doi.org/10.1016/j.eurpolymj.2017.12.045

Sill TJ, von Recum HA (2008) Electrospinning: applications in drug delivery and tissue engineering. Biomaterials 29:1989–2006

Deitzel JM, Kosik W, McKnight SH et al (2001) Electrospinning of polymer nanofibers with specific surface chemistry. Polymer (Guildf) 43:1025–1029. https://doi.org/10.1016/S0032-3861(01)00594-8

Ramakrishna S, Mayer J, Wintermantel E, Leong KW (2001) Biomedical applications of polymer-composite materials: a review. Compos Sci Technol 61:1189–1224. https://doi.org/10.1016/S0266-3538(00)00241-4

Chong EJ, Phan TT, Lim IJ et al (2007) Evaluation of electrospun PCL/gelatin nanofibrous scaffold for wound healing and layered dermal reconstitution. Acta Biomater 3:321–330. https://doi.org/10.1016/j.actbio.2007.01.002

Beachley V, Wen X (2010) Polymer nanofibrous structures: fabrication, biofunctionalization, and cell interactions. Prog Polym Sci 35:868–892

Wen MH, Cheng PW, Liao LJ, Chou HW, Wang CT (2013) Treatment outcomes of injection Laryngoplasty using cross-linked porcine collagen and hyaluronic acid. Otolaryngol Head Neck Surg 149:900–906

Qian YF, Su Y, Li XQ et al (2010) Electrospinning of polymethyl methacrylate nanofibres in different solvents. Iran Polym J (English Ed) 19:123–129

Mohammadian M, Haghi AK (2014) Systematic parameter study for nano-fiber fabrication via electrospinning process. Bulg Chem Commun 46:545–555

Casasola R, Thomas NL, Trybala A, Georgiadou S (2014) Electrospun poly lactic acid (PLA) fibres: effect of different solvent systems on fibre morphology and diameter. Polymer (Guildf) 55:4728–4737. https://doi.org/10.1016/j.polymer.2014.06.032

Jahangir MA, Rumi TM, Wahab A et al (2017) Poly lactic acid (PLA) Fibres: different solvent systems and their effect on fibre morphology and diameter. Am J Chem 2017:177–186. https://doi.org/10.5923/j.chemistry.20170706.01

Huang Y, Lu Y, Chen J (2016) Magnetic graphene oxide as a carrier for targeted delivery of chemotherapy drugs in cancer therapy. J Magn Magn Mater 427:34–40. https://doi.org/10.1016/j.jmmm.2016.10.042

Rong Z, Zeng W, Kuang Y, Zhang J, Liu X, Lu Y, Cheng X (2015) Enhanced bioactivity of osteoblast-like cells on poly(lactic acid)/poly(methyl methacrylate)/nano-hydroxyapatite scaffolds for bone tissue engineering. Fibers Polym 16:245–253. https://doi.org/10.1007/s12221-015-0245-0

Buschle-Diller G, Cooper J, Xie Z, Wu Y, Waldrup J, Ren X (2007) Release of antibiotics from electrospun bicomponent fibers. Cellulose 14:553–562. https://doi.org/10.1007/s10570-007-9183-3

Taylor G (1969) Electrically driven jets. Proc R Soc A Math Phys Eng Sci 313:453–475. https://doi.org/10.1098/rspa.1969.0205

Hadjiargyrou M, Chiu JB (2008) Enhanced composite electrospun nanofiber scaffolds for use in drug delivery. Expert Opin Drug Deliv 5:1093–1106

Herrero-Herrero M, Gómez-Tejedor JA, Vallés-Lluch A (2018) PLA/PCL electrospun membranes of tailored fibres diameter as drug delivery systems. Eur Polym J 99:445–455. https://doi.org/10.1016/j.eurpolymj.2017.12.045

Liu H, Ding X, Zhou G, Li P, Wei X, Fan Y (2013) Electrospinning of nanofibers for tissue engineering applications. J Nanomater 2013:1–11

Zhang C, Wang J, Wang Y (2005) Solubility of ceftriaxone disodium in acetone, methanol, ethanol, N,N,-dimethylformamide, and formamide between 278 and 318 K. J Chem Eng Data 50:1757–1760. https://doi.org/10.1021/je0501989

Wannatong L, Sirivat A, Supaphol P (2004) Effects of solvents on electrospun polymeric fibers: preliminary study on polystyrene. Polym Int 53:1851–1859. https://doi.org/10.1002/pi.1599

Fong H, Chun I, Reneker DH (1999) Beaded nanofibers formed during electrospinning. In: Polymer 40:4585–4592. https://doi.org/10.1016/S0032-3861(99)00068-3

Németh C, Gyarmati B, Gacs J, Salakhieva DV, Molnár K, Abdullin T, László K, Szilágyi A (2020) Fast dissolving nanofibrous matrices prepared by electrospinning of polyaspartamides. Eur Polym J 130:130. https://doi.org/10.1016/j.eurpolymj.2020.109624

Cui W, Li X, Zhu X, Yu G, Zhou S, Weng J (2006) Investigation of drug release and matrix degradation of electrospun poly(DL-lactide) fibers with paracetanol inoculation. Biomacromolecules 7:1623–1629. https://doi.org/10.1021/bm060057z

Zargham S, Bazgir S, Tavakoli A, Rashidi AS, Damerchely R (2012) The effect of flow rate on morphology and deposition area of electrospun nylon 6 Nanofiber. J Eng Fiber Fabr 7:155892501200700. https://doi.org/10.1177/155892501200700414

Akl MA, Ahmed MA, Ramadan A (2011) Validation of an HPLC-UV method for the determination of ceftriaxone sodium residues on stainless steel surface of pharmaceutical manufacturing equipments. J Pharm Biomed Anal 55:247–252. https://doi.org/10.1016/j.jpba.2011.01.020

Acknowledgments

The work has been supported by the Yildiz Technical University Scientific Research Projects Coordination Department. Project Number FDK-2019-3531.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Duygulu, N.E., Ciftci, F. & Ustundag, C.B. Electrospun drug blended poly(lactic acid) (PLA) nanofibers and their antimicrobial activities. J Polym Res 27, 232 (2020). https://doi.org/10.1007/s10965-020-02215-0

Published:

DOI: https://doi.org/10.1007/s10965-020-02215-0