Abstract

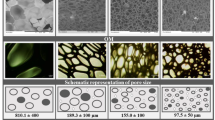

In this study the use of polyurethane foam (PUF) as a heat seal coating for potential application in medical pouch packaging were investigated. We prepared PUF coatings at various foam densities and cell densities through mechanical foaming at various stirring speeds; then used a LUMisizer to examine their stabilities. After applying PUF coatings of various foam densities onto a medical packaging material (Tyvek®) at various thicknesses, then employed impulse heat sealing with linear low density polyethylene (LLDPE) films to fabricate medical pouches. In addition to investigating the morphology, tack properties, adhesion, scratch resistance, flexibility, and durability of the PUF coats, the peel strength and air permeability of the medical pouches were also measured. Increasing the foam density of the PUF coatings increased their stability; the PUF coats prepared at a higher foam density exhibited greater tackiness (<1 g/cm2), adhesion (5B), scratch resistance (HB), flexibility (passes), and durability (ΔYI ≤ 5). The peel strength measured in the T-peel configuration increased upon increasing the foam density and decreasing the coating thickness of the PUF coat/LLDPE pouches. The air permeability of the pouches increased upon increasing the foam density and cell density of the PUF coat/LLDPE pouches. Morphological studies using scanning electron microscopy were consistent with the experimental results.

Similar content being viewed by others

References

Szycher M (1999) Szycher’s handbook of polyurethanes. CRC Press, Boca Raton

Bao LH, Lan YJ, Zhang SF (2006) J Polym Res 13:507–514

Chen JJ, Zhu CF, Deng HT, Qin ZN, Bai YQ (2009) J Polym Res 16:375–380

Sandip DD, Jigar VP, Vijay KS (2003) Int J Adhes Adhes 23:393–399

Yang SR, Kwon OJ, Kim DH, Park JS (2007) Fiber Polym 8:257–262

Neilsen MK, Krieg RD, Schreyer HL (1995) Polym Eng Sci 35:387–394

Odell RB (2001) U.S. Patent 6189292

Stokes VK, Hobbs SY (1989) Polym Eng Sci 29:1667–1676

Mueller C, Capaccio G, Hiltner A, Baer E (1998) J Appl Polym Sci 70:2021–2030

Woo L, Ding SY, Ling MTK, Westphal SP (1997) J Therm Anal Calorim 49:131–138

Hwo CC (1987) U.S. Patent 4665130

Dinesh A, Hugh L, Rafael A, Krittika T (2006) J Plast Film Sheet 22:247–263

Sherman M (1998) Medical device packaging handbook. Marcel Dekker, New York

Frisch KC (1995) Advances in urethane ionomers. Technomic Publishing, Pennsylvania

Morris BA (2002) J Plast Film Sheet 18:157–167

Klempner D (1991) Handbook of polymeric foams and foam technology. Hanser, New York

Stephens PJ (1998) U.S. Patent 5803596

Roff WF (1971) Fibres, films, plastics and rubbers—a handbook of common polymers. Butterworths, UK

Goods SH, Neuschwanger CL, Whinnery LL, Nix WD (1999) J Appl Polym Sci 74:2724–2736

ASTM D823 (2007) Standard practices for producing films of uniform thickness of paint, varnish, and related products on test panels

Lerche D (2002) J Disper Sci Technol 23:699–709

Zeng CC, Nemat H, Zhang C, Wang B (2010) Polymer 51:655–664

ISO 11135-1 (2007) Sterilization of health care products. Ethylene oxide part 1: requirements for development, validation and routine control of a sterilization process for medical devices

ASTM D2979 (2009) Standard test method for pressure-sensitive tack of adhesives using an inverted probe machine

ASTM D3359 (2002) Standard test methods for measuring adhesion by tape test

ASTM D3363 (2005) Standard test method for film hardness by pencil test

ASTM D552 (1997) Standard method for mandrel bend test of attached organic coatings

ASTM G154 (2006) Standard practice for operating fluorescent light apparatus for UV exposure of nonmetallic materials

ASTM E313 (2010) Standard practice for calculating yellowness and whiteness indices from instrumentally measured color coordinates

ASTM F88 (2009) Standard test method for seal strength of flexible barrier materials

ISO 5636-5 (2003) Paper and board. Determination of air permeance and air resistance (Medium range) part 5: Gurley method

Chiu HT, Chang CY, Chiang TY, Kuo MT, Wang YH (2011) Using analytical centrifugation to characterize the dispersibility and particle size distributions of organic/inorganic composite coatings. J Polym Res. doi:10.1007/s10965-011-9563-0

Lerche D, Sobisch T (2007) Powder Technol 174:46–49

Kurt CF (1973) Plastic foams part II. Marcel Dekker, New York

Goods SH, Neuschwanger CL, Henderson CC, Skala DM (1998) J Appl Polym Sci 68:1045–1055

Curvers D, Saveyn H, Scales PJ, Van der Meeren P (2009) Chem Eng J 148:405–413

Niyogi D, Kumar R, Gandhi KS (1992) AICHE J 38:1170–1184

Niyogi D, Kumar R, Gandhi KS (1999) Polym Eng Sci 39:199–209

Zhang XD, Macosko CW, Davis HT, Nikolov AD, Wasan DT (1999) J Colloid Interface Sci 215:270–279

Meka P, Stehling FC (1994) J Appl Polym Sci 51:89–103

Stehling FC, Meka P (1994) J Appl Polym Sci 51:105–119

Yuan CS, Hassan A, Ghazali MIH, Ismail AF (2007) J Appl Polym Sci 104:3736–3745

Barcan DS (2006) U.S. Patent 0277975

Hugh RB, Thomas PR (1996) Macromolecules 29:798–800

Mckelvey JM (1962) Polymer processing. Wiley, New York

Jeffrey JW (2001) Encyclopedia of polymer science and technology. Wiley, New York

Acknowledgments

The authors gratefully acknowledge the experimental support from Sigma Medical Supplies Corp., Viewstar CO., LTD. and Dr. Zhenhua Chen of High-Performance Materials Institute, Florida State University

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chiu, HT., Chang, CY., Pan, HW. et al. Characterization of polyurethane foam as heat seal coating in medical pouch packaging application. J Polym Res 19, 9791 (2012). https://doi.org/10.1007/s10965-011-9791-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-011-9791-3