Abstract

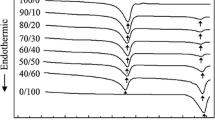

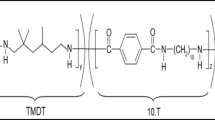

Isotactic polypropylene(PP)/glass fiber(GF) composites were modified by grafting polymerization of polyfunctional monomer, pentaerythritol triacrylate (PETA), in the presence of 2,5-dimethyl-2,5-di(tert-butylperoxy) hexane peroxide (DDHP) via melt extrusion. Fourier transform infrared spectroscopy (FTIR), melt strength test (MS), mechanical property test, differential scanning calorimetry (DSC) and X-ray diffraction (XRD) were used to characterize the microstructure and properties of the modified composites. The crystallization kinetics was investigated by Mo method while apparent activation energy of crystallization of the composites was determined by Kissinger method. The FTIR results showed that the acrylic polymers were grafted onto the polypropylene chains. The grafting made the melt strengths and the mechanical properties of the modified composites, and the interfacial adhesion between PP and glass fiber all enhanced. High melting and crystallization temperatures, high crystallization rate and large activation energy of crystallization were also obtained after grafting. In addition, the grafted acrylic polymers recovered the depressed crystallization of polypropylene and restrained α-β transition in fatigue experiment.

Similar content being viewed by others

References

Langston J, Dong JY, Chung TC (2005) Macromolecules 38(14):5849–5853

Karian HG (ed) (2003) Handbook of polypropylene and polypropylene composites, 2nd edn. Marcel Dekker, New York

Yu J, He J (2000) Polymer 41:891–898

Morelli CL, Pouzada AS, Sousa JA (2009) J Appl Polym Sci 114:3592–3601

Nishitani Y, Sekiguchi I, Hausnerova B, Zdrazilova N, Kitano T (2007) Polym Compos 15(2):111–119

Felix AHO, Cardozo NSM, Nachtigall SMB, Mauler RS (2006) Macromol Mater Eng 291:418–427

Li Y, Chen LX, Zhou XD (2008) J Mater Sci 43(15):5083–5091

Zhou SH, Gao Y, Wang YT, Hu CP, Dong QZ (2007) J Appl Polym Sci 104:1661–1670

Kumar KS, Ghosh AK, Bhatnagar N (2007) J Reinf Plast Compos 26(3):239–249

Kumar KS, Ghosh AK, Bhatnagar N (2007) Polym Compos 28(2):259–266

Xie HQ, Zhang S, Xie D (2005) J Appl Polym Sci 96:1414–1420

Graebling D (2002) Macromolecules 35:4602–4610

Kim BK, Kim KJ (1993) Adv Polym Tech 12(3):263–269

Wang XC, Tzoganakis C, Rempel GL (1996) J Appl Polym Sci 61:1395–1404

Tian JH, Yu W, Zhou CX (2006) Polymer 47:7962–7969

Tian JH, Yu W, Zhou CX (2006) J Macromol Sci Part B Physics 45:969–985

Guillet JE, Combs RL, Slonaker DF, Weemes DA, Coover HW (1965) J Appl Polym Sci 8:757–765

Tabatabaei SH, Carreau PJ, Ajji A (2009) Chem Eng Sci 64:4719–4731

Wang Y, Run M (2009) J Polym Res 16:725–737

Avrami M (1940) J Chem Phys 8:212–224

Zhang Y, Jiang X, Guan Y, Zheng A (2005) Mater Lett 59:3626–3634

Dejuana R, Jauregui A, Calahorra E, Cortazar M (1996) Polymer 37:3339–3345

Jeziorny A (1978) Polymer 19:1142–1144

Ozawa T (1971) Polymer 12:150–158

Liu JP, Mo ZS, Qi YC, Zhang HF, Chen DL (1993) Acta Polym Sin 1:1–6, In Chinese

Kissinger HE (1956) J Res Natl Bur Stand 57:217–221

Ni QL, Fan JQ, Dong JY (2009) J Appl Polym Sci 114:2180–2194

Lugão AB, Cardoso E, Lima LF, Hustzler B, Tokumoto S (2003) Nucl Instrum Methods Phys Res Sect B 208:252–255

Ye CM, Liu JJ, Mo ZS, Tang GB, Jing XB (1996) J Appl Polym Sci 60:1877–1881

Turner-Jones A, Aizlewood JM, Beckett DR (1964) Makromol Chem 75:134–158

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ni, Q., Zhu, X., Wang, Y. et al. Microstructure and properties of polypropylene/glass fiber composites grafted with poly(pentaerythritol triacrylate). J Polym Res 18, 917–926 (2011). https://doi.org/10.1007/s10965-010-9489-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9489-y