Abstract

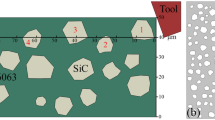

The paper presents the results of experimental investigation on mechanical and machinability properties of A332-Al2O3/SiCp reinforced using varying size of particles up to 53 μm by a vortex method was carried out at different cutting conditions. Experiments were carried out with TiN (K10) coated carbide tools and TP30 coated carbide tools at various cutting speeds The influence of reinforced ratios of 10 wt% of Al2O3/SiCp on mechanical properties was examined. The effect of machining parameters, e.g. cutting speed, feed rate and depth of cut on flank wear land and surface roughness was studied. It was observed that decreased with increasing the particle size produced better mechanical properties such as tensile strength and hardness, but wear showed different trend; increased with decreasing the particle size. Machinability properties of the selected material were studied and with increasing the particle size surface roughness was generally affected by feed rate and cutting speed.

Similar content being viewed by others

References

Y.R. Kevin Chou, J. Liu, CVD diamond tool performance in metal matrix composite machining. Surf. Coat. Tech. 200, 1872–1878 (2005)

N. Barman, P. Kumar, P. Dutta, Studies on transport phenomena during solidification of an aluminum alloy in the presence of linear electromagnetic stirring. J. Mater. Proc. Tech. 209, 5912–5923 (2009)

R. Chen, G. Zhang, Casting defects and properties of cast A356 aluminium alloy reinforced with SiC particles. Compos Sci and Tech 47(1), 51–56 (1993)

P.D. Shashi, S. Satpal, K.M. Raghvendra, Microstructure and mechanical properties of A356/SiC composites fabricated by electromagnetic stir casting. Proc. Mater. Sci. 6, 1524–1532 (2014)

P. Rohatgi, Cast aluminium matrix composites for automotive applications. J. Organomet. Chem. 43, 10–15 (1991)

J. Dinwoodie, Automotive applications for MMCs based on short staple alumina fibres SAE Tech Paper Series. International conference of experience, Detroit, Michigan, February 1987, pp. 23–27

S.S. Joshi, N. Ramakrishnan, D. Sarathy, P. Ramakrishnan, Development of the technology for discontinuously reinforced aluminium composites, The First Wold Conference on Integrated Design and Process Technology, Austin, Vol. 1, 1995, pp. 492–497

M.J. Kocazac, S.C. Khatri, J.E. Allison, M.G. Bader . MMCs for ground vehicle, aerospace and industrial applications. in Fund Met Mat Compos Butterworth, ed. by Süpesh et al (Guildford, 1993)

G.A. Chadwich, P.J. Heath, Machining of metal matrix composites. Met. Mater. 26, 73–76 (1990)

Y. Sahin, M. Kok, H. Celik, Tool wear and surface roughness of Al2O3 particle-reinforced aluminium alloy composites. J. Mater. Process. Tech. 128, 280–291 (2002)

I.A. Ibrahim, F.A. Mohamed, E.J. Lavernia, Particulate reinforced metal matrix composite a review. J. Mater. Sci. 26, 1137–1156 (1991)

Y.X. Lu, X.M. Meng, C.S. Lee, Microstructure and mechanical behaviour of a SiC particles reinforced Al-5Cu composite under dynamic loading. J. Mater. Process. Tech. 94, 175–178 (1999)

P.M. Bronsveld, P. Bruinsma, JThDe Hosson, Microstructural analysis of hot is statically pressed Al-SiC. Mater. Sci. Eng. A135, 77–81 (1991)

J.H. Tweed, Manufacture of 2014 aluminium reinforced with SiC particulate by vacuum hot pressing. Mater. Sci. Eng. A135, 73–76 (1991)

A. Lawley, M.G. Koczak, R. Orban, Fabrication of Nano crystalline NiAl compacts via combined mechanical alloying and self-propagating synthesis, European Conference on Advanced PM Materials (EPMA, Birmingham, 1995), pp. 23–25

H. Arik, M. Türker, S. Saritas. Investigation of the mechanical properties of in’situ Al4C3 reinforced aluminium based composites by mechanical alloying technique. in Powder Metallurgy World Congress and Exhibition, (Kyoto, Tokyo, 2000, pp. 543–549)

M. Türker, Long term oxidation behaviour of ferritic ODS alloys at the temperature range 1100–1200 °C in air and nitrogen 2% oxygen. Corros. Sci. 4–1(1), 1–15 (1999)

Y. Özçatalbaş, Investigation of the machinability behaviour of Al4C3 reinforced Al-based composite produced by mechanical alloying technique. Comp. Sci. Tech. 63, 53–61 (2003)

T. Ozben, E. Kilickap, O. Cakır. Investigation of mechanical and machinability properties of SiC particle reinforced Al-MMC. J. Mater. Proc. Techn. 2008;1 9 8:220–225

Y.Q. Wang, A.M. Afsar, J.H. Jang, K.S. Han, J.J. Song, Room temperature dry and lubricant wear behaviors of Al2O3f/SiCp/Al hybrid metal matrix composites. Wear 268, 863–870 (2010)

M.A. Azmah Hanim, S. Chang Chung, O. Khang Chuan, Effect of a two-step solution heat treatment on the microstructure and mechanical properties of 332 aluminum silicon cast alloy. Mater. Des. 32, 2334–2338 (2011)

N. Altınkök. The fabrıcatıon of Al2O3/SiC partıcle reınforced metal matrıx composıtes used in automotıve industry and investıgatıon of theır mechanıcal behavıours, (PhD Thesis Sakarya University Turkey 2002). pp. 130–140

Y. Yamada, K. Shimojima, M. Mabuchi, M. Nakamura, T. Asahina, T. Mukai, H. Kanahashi, K. Higashi, Compressive deformation behavior of Al2O3 foam. Mater. Sci. Eng., A 277, 213–217 (2000)

D. Cree, M. Pugh, Dry wear and friction properties of an A356/SiC foam interpenetrating phase composite. Wear 272, 88–96 (2011)

Wang Yi-qi, Song J-il, Dry sliding wear behavior of Al2O3 fiber and SiC particle reinforced aluminium based MMCs fabricated by squeeze casting method. Trans. Nonfer. Met. Soc. Chin. 21, 1441–1448 (2011)

S.V. Kamat, M. Manoharan, Work hardening behaviour of alumuna particulate reinforced 2024 aluminium alloys matrixs composites. J. Comp. Mater. 27, 1714–1721 (1993)

R.J. Arsenault, L. Wang, C.R. Feng, Strengthening of composites due to microstructural changes in the matrix. Acta Metal. Mater. 39, 47–57 (1991)

X.P. Li, K.H.W. Seah, A pressured air jet approach to tool wear minimization in cutting of metal matrix composites. Wear 255, 1352–1358 (2003)

L. Cronjager, Machining of fibre and particles reinforced aluminium. Ann. CIRP 41, 63–66 (1992)

A.R. Chambers, S.E. Stephens, Machining of Al–5 Mg reinforced with 5 vol% saffil and 15 vol% SiC fibres. J. Mater. Sci. Eng. A 135, 287–290 (1990)

Y.M. Quan, Z.H. Zhou, B.Y. Ye, Cutting process and chip appearance of Al matrix composites reinforced by SiC particles. J. Mater Process. Tech. 91, 231–235 (1999)

Z. Zhao, S. Zhijian, X. Yingkun, Effect of microstructure on the mechanical properties of an Al alloy 6061–SiC particle reinforced composite. Mater. Sci. Eng. 132, 88–93 (1991)

U.A. Dabade, S.S. Joshi, Analysis of chip formation mechanism in machining of Al/SiCp metal matrix composites. J. Mater. Proc. Tech. 209, 4704–4710 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Altınkök, N. Investigation of mechanical and machinability properties of Al2O3/SiCp reinforced Al-based composite fabricated by stir cast technique. J Porous Mater 22, 1643–1654 (2015). https://doi.org/10.1007/s10934-015-0048-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-015-0048-0