Abstract

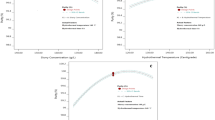

This investigation was aimed at preparing nanocrystalline TiO2 powder by solution combustion method, and searching the optimum preparing conditions by employing Taguchi robust design method. Taguchi robust design method with L18 orthogonal array was implemented to optimize experimental conditions for preparing nano-sized titania particles. Titanium IV n-butoxide was hydrolyzed to obtain titany1 hydroxide [TiO(OH)2], and titanyl nitrate [TiO(NO3)2] was obtained by reaction of TiO(OH)2 with nitric acid. Finally, the aqueous solution containing titanyl nitrate [TiO(NO3)2] and a fuel, glycine, were mixed and combusted to obtain the nano-sized titania. The optimum conditions obtained by this method are as follows (based on 1 mol of TiO2 per batch): concentration of HPC, 0.053 mg cm−3; mole ratio of Ti:H2O:IPA, 1:4:10; hydrolysis time, one hr; the amounts of HNO3 and glycine are 10 ml and 0.5 g, respectively; nitrated temperature, 298 K and nitrated time, 2 h. TiO2 nanocrystalline (∼15 nm) with high BET surface area (350 m2 g−1) and narrow band gap energy (2.7 eV) were thus obtained.

Similar content being viewed by others

References

K. Honda and A. Fujishima, Nature 37, 238 (1972).

A. Fujishima, T.N. Rao, and D.A. Tryk, J. Photochemistry and Photobiology C: Photochemistry Reviews 1, 1 (2000).

H. Furube, T. Asahi, H. Masuhara, H. Yamashita, and M. Anpo, Chem. Phys. Lett. 336, 424 (2001).

R. Asahi, T. Morikawa, T. Ohwaki, K. Aoki, and Y. Taga, Science 269, 293 (2001).

S.U.M. Khan, M. Al-Shahry, and W. B. Ingler, Science 2243, 297 (2002).

T. Sugimoto and X. Zhou, J. Collids Interface Sci. 252, 347 (2002).

C.D. Terwilliger and Y.M. Chiang, Nanostruct. Mater. 2, 37 (1993).

E.J. Kim and S.H. Hahn, Mater. Sci. Eng. A 303, 24 (2001).

X.Z. Guo, B.G. Ravi, P.S. Devi, J.C. Hanson, J. Margolies, R.J. Gambino, J.B. Parise, and S. Sampath, Journal of Magnetism and Magnetic Materials 145, 295 (2005).

S. Ekambaram, K.C. Patil, and M. Maaza, Journal of Alloys and Compounds 381, 393 (2005).

S. Lee and B. Jun, Ceramics International 53, 31 (2005).

C.L. Chu, C.Y. Chung, and P.H. Lin, Materials Science and Engineering A 106, 392 (2005).

G. Taguchi, Introduction to Quality Engineering, Asian Productivity Organization, Tokyo, 1990.

P.J. Ross and G. Taguchi, Techniques for Quality Engineering, McGrawHill, New York, 1998.

R.K. Roy, A primer on the Taguchi method, Society of Manufacturing Engineers, Michigan, 1990.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C.M., Wu, H. & Chung, S.L. Optimization of experimental conditions based on Taguchi robust design for the preparation of nano-sized TiO2 particles by solution combustion method. J Porous Mater 13, 307–314 (2006). https://doi.org/10.1007/s10934-006-8022-5

Issue Date:

DOI: https://doi.org/10.1007/s10934-006-8022-5