Abstract

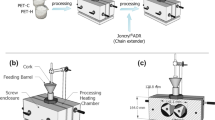

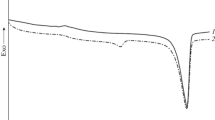

This study investigates the effect of using a multifunctional epoxide chain extender (Joncryl® ADR 4468) on the thermal stabilization and rheological properties of recycled polyethylene terephthalate (R-PET) and its blends with polybutylene terephthalate (PBT). The R-PET samples were prepared without and with chain extender (CE) contents of 0.4 wt% and 0.8 wt%. R-PET/PBT blends with weight ratios of 75w/25w, 50w/50w and 25w/75w were also prepared without and with a given CE content of 0.2 wt%. The thermal stability of the melt blended samples was analyzed through small amplitude oscillatory shear (SAOS) rheological experiments. The structure of the samples was evaluated using a Fourier transform infrared (FTIR) spectrometer. While the dynamic rheological properties of R-PET were improved with the addition of Joncryl and by blending with PBT, during the SAOS rheological experiments, the complex viscosity of R-PET further increased due to the concurrent polycondensation of R-PET and the resumption of Joncryl reaction with R-PET molecules. These reactions during the rheological experiments were further expedited with increasing the testing temperature. On the other hand, in R-PET/PBT blends, the reactivity of Joncryl was more noticeable in blends with higher R-PET contents due to the higher available internal reactive sites of much shorter R-PET molecules. It was observed that the addition of only 0.2 wt% Joncryl to the blends of R-PET/PBT (75w/25w) dramatically improves the thermal stability and dynamic rheological properties of R-PET and most likely its processability.

Similar content being viewed by others

References

Utracki LA (2013) Commercial polymer blends. Springer Science & Business Media

Kannan G, Grieshaber SE, Zhao W (2016) Thermoplastic polyesters. Handb Thermoplast 41:319

Lepoittevin B, Roger P (2011) Poly (ethylene terephthalate). Handb Eng Spec Thermoplast 3:97–126

Ghanbari A, Heuzey MC, Carreau PJ, Ton-That MT (2013) A novel approach to control thermal degradation of PET/organoclay nanocomposites and improve clay exfoliation. Polymer 54:1361–1369. https://doi.org/10.1016/j.polymer.2012.12.066

Raffa P, Coltelli M-B, Savi S, Bianchi S (2012) Castelvetro, Chain extension and branching of poly (ethylene terephthalate) (PET) with di-and multifunctional epoxy or isocyanate additives: An experimental and modelling study. React Funct Polym 72:50–60. https://doi.org/10.1016/j.reactfunctpolym.2011.10.007

Xu XF, Ghanbari A, Leelapornpisit W, Heuzey MC, Carreau P (2011) Effect of ionomer on barrier and mechanical properties of PET/Organoclay nanocomposites prepared by melt compounding. Int Polym Process 26(4):444–455. https://doi.org/10.3139/217.2477

Zhang Y, Guo W, Zhang H, Wu C (2009) Influence of chain extension on the compatibilization and properties of recycled poly (ethylene terephthalate)/linear low density polyethylene blends. Polym Degrad Stab 94:1135–1141. https://doi.org/10.1016/j.polymdegradstab.2009.03.010

Shen L, Worrell E, Patel MK (2010) Open-loop recycling: a LCA case study of PET bottle-to-fibre recycling. Resour Conserv Recycl 55:34–52. https://doi.org/10.1016/j.resconrec.2010.06.014

Galanty PG, Richardson JJ (1988) Polyethylene Terephthalates (PET). ASM Int. Eng. Plast Eng Mater Handbook 2:172–176

MacArthur DE, Waughray D, Stuchtey MR (2016) The new plastics economy, rethinking the future of plastics. In: World Econ. Forum

Gourmelon G (2015) Global plastic production rises, recycling lags. Vital Signs 22:91–95

Al-Sabagh AM, Yehia FZ, Eshaq G, Rabie AM, ElMetwally AE (2016) Greener routes for recycling of polyethylene terephthalate. Egypt J Pet 25:53–64. https://doi.org/10.1016/j.ejpe.2015.03.001

Sang T, Wallis CJ, Hill G, Britovsek GJP (2020) Polyethylene terephthalate degradation under natural and accelerated weathering conditions. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2020.109873

European Union (2019) Turning the tide on single use plastics. [Brochure] https://op.europa.eu/en/publication-detail/-/publication/fbc6134e-367f-11ea-ba6e-01aa75ed71a1

Badia JD, Strömberg E, Karlsson S, Ribes-Greus A (2012) The role of crystalline, mobile amorphous and rigid amorphous fractions in the performance of recycled poly (ethylene terephthalate) (PET). Polym Degrad Stab 97:98–107. https://doi.org/10.1016/j.polymdegradstab.2011.10.008

Kang DH, Auras R, Vorst K, Singh J (2011) An exploratory model for predicting post-consumer recycled PET content in PET sheets. Polym Test 30:60–68. https://doi.org/10.1016/j.polymertesting.2010.10.010

G.P. Karayannidis, E.A. Psalida (2000) Chain extension of recycled poly (ethylene terephthalate) with 2, 2′-(1, 4‐phenylene) bis (2‐oxazoline), J. Appl. Polym. Sci. 77:2206–2211

Japon S, Boogh L, Leterrier Y, Månson J-A (2000) Reactive processing of poly (ethylene terephthalate) modified with multifunctional epoxy-based additives. Polymer 41:5809–5818. https://doi.org/10.1016/S0032-3861(99)00768-5

Torres N, Robin JJ, Boutevin B (2000) Study of thermal and mechanical properties of virgin and recycled poly (ethylene terephthalate) before and after injection molding. Eur Polym J 36:2075–2080. https://doi.org/10.1016/S0014-3057(99)00301-8

Awaja F, Daver F, Kosior E (2004) Recycled poly (ethylene terephthalate) chain extension by a reactive extrusion process. Polym Eng Sci 44:1579–1587. https://doi.org/10.1002/pen.20155

Zhang Y, Zhang C, Li H, Du Z, Li C (2010) Chain extension of poly (ethylene terephthalate) with bisphenol-A dicyanate. J Appl Polym Sci 117:2003–2008. https://doi.org/10.1002/app.32136

Incarnato L, Scarfato P, Di Maio L, Acierno D (2000) Structure and rheology of recycled PET modified by reactive extrusion. Polymer 41:6825–6831. https://doi.org/10.1016/S0032-3861(00)00032-X

Costa ARM, Almeida TG, Silva SML, Carvalho LH, Canedo EL (2015) Chain extension in poly (butylene-adipate-terephthalate). Inline testing in a laboratory internal mixer. Polym Test 42:115–121. https://doi.org/10.1016/j.polymertesting.2015.01.007

Berg D, Schaefer K, Moeller M (2019) Impact of the chain extension of poly (ethylene terephthalate) with 1, 3-phenylene‐bis‐oxazoline and N, N′‐carbonylbiscaprolactam by reactive extrusion on its properties. Polym Eng Sci 59:284–294. https://doi.org/10.1002/pen.24903

Jacques B, Devaux J, Legras R, Nield E (1996) Reactions induced by triphenyl phosphite addition during melt mixing of poly (ethylene terephthalate)/poly (butylene terephthalate) blends: influence on polyester molecular structure and thermal behaviour. Polymer 37:1189–1200. https://doi.org/10.1016/S0032-3861(97)00097-9

Jacques B, Devaux J, Legras R, Nield E (1996) Investigation on model molecules of the reactions induced by triphenyl phosphite addition during polyester processing. Macromolecules 29:3129–3138

Jacques B, Devaux J, Legras R, Nield E (1997) Reactions induced by triphenyl phosphite addition during melt mixing of PET/PBT blends: chromatographic evidence of a molecular weight increase due to the creation of bonds of two different natures. Polymer 38:5367–5377. https://doi.org/10.1016/S0032-3861(97)00097-9

Pesetskii SS, Shevchenko VV, Dubrovsky VV (2018) Morphology and properties of poly (ethylene terephthalate) and thermoplastic polyester elastomer blends modified in the melt by a diisocyanate chain extender and filled with a short glass fiber. J Appl Polym Sci 135:45711. https://doi.org/10.1002/app.45711

Tuna B, Ozkoc G (2017) Effects of diisocyanate and polymeric epoxidized chain extenders on the properties of recycled poly (lactic acid). J Polym Environ 25:983–993. https://doi.org/10.1007/s10924-016-0856-6

Arayesh H, Golshan Ebrahimi N, Khaledi B, Khabazian Esfahani M (2020) Introducing four different branch structures in PET by reactive processing: a rheological investigation. J Appl Polym Sci. https://doi.org/10.1002/app.49243

Kahraman Y, Özdemir B, Kılıç V, Goksu YA, Nofar M (2021) Super toughened and highly ductile PLA / TPU blend systems by in situ reactive interfacial compatibilization using multifunctional epoxy-based chain extender. J Appl Polym Sci 138(20):50457. https://doi.org/10.1002/app.50457

Nofar M, Salehiyan R, Sinha Ray S (2019) Rheology of poly (lactic acid)-based systems. Polym Rev 59:465–509. https://doi.org/10.1080/15583724.2019.1572185

Nofar M, Zhu W, Park CB, Randall J (2011) Crystallization kinetics of linear and long-chain-branched polylactide. Ind Eng Chem Res 50:13789–13798. https://doi.org/10.1021/ie2011966

Nofar M (2018) Synergistic Effects of Chain Extender and Nanoclay on the Crystallization Behavior of Polylactide. Int J Mater Sci Res 1:1–8. https://doi.org/10.18689/ijmsr-1000101

Jalali A, Huneault MA, Nofar M, Lee PC, Park CB (2019) Effect of branching on flow-induced crystallization of poly (lactic acid). Eur Polym J 119:410–420. https://doi.org/10.1016/j.eurpolymj.2019.07.045

Standau T, Nofar M, Dorr D, Altstädt V (2021) A review on multifunctional epoxy-based Joncryl® ADR chain extended thermoplastics” . Polym Rev. https://doi.org/10.1080/15583724.2021.1918710

Villalobos M, Awojulu A, Greeley T, Turco G, Deeter G (2006) Oligomeric chain extenders for economic reprocessing and recycling of condensation plastics. Energy 31(15):3227–3234. https://doi.org/10.1016/j.energy.2006.03.026

Raffa P, Coltelli MB, Castelvetro V (2014) Expanding the application field of post-consumer poly (ethylene terephthalate) through structural modification by reactive blending. J Appl Polym Sci. https://doi.org/10.1002/app.40881

Tavares AA, Silva DF, Lima PS, Andrade DL, Silva SM, Canedo EL (2016) Chain extension of virgin and recycled polyethylene terephthalate. Polym Test 50:26–32. https://doi.org/10.1016/j.polymertesting.2015.11.020

Duarte IS, Tavares AA, Lima PS, Andrade DL, Carvalho LH, Canedo EL, Silva SM (2016) Chain extension of virgin and recycled poly (ethylene terephthalate): Effect of processing conditions and reprocessing. Polym Degrad Stab 124:26–34. https://doi.org/10.1016/j.polymdegradstab.2015.11.021

Xiao L, Wang H, Qian Q, Jiang X, Liu X, Huang B, Chen Q (2012) Molecular and structural analysis of epoxide-modified recycled poly (ethylene terephthalate) from rheological data. Polym Eng Sci 52:2127–2133. https://doi.org/10.1002/pen.23175

Härth M, Dörnhöfer A, Kaschta J, Münstedt H, Schubert DW (2021) Molecular structure and rheological properties of a poly (ethylene terephthalate) modified by two different chain extenders. J Appl Polym Sci 138(13):50110. https://doi.org/10.1002/app.50110

Nofar M, Oğuz H (2019) Development of PBT/recycled-PET blends and the influence of using chain extender. J Polym Environ 27:1404–1417. https://doi.org/10.1007/s10924-019-01435-w

Escala A, Stein RS (1979) Crystallization studies of blends of polyethylene terephthalate and polybutylene terephthalate. ACS Publications. DOI:https://doi.org/10.1021/ba-1979-0176.ch024

Avramova N (1995) Amorphous poly (ethylene terephthalate)/poly (butylene terephthalate) blends: miscibility and properties. Polymer 36:801–808. https://doi.org/10.1016/0032-3861(95)93111-X

Szostak M (2004) Mechanical and thermal properties of PET/PBT blends. Mol Cryst Liq Cryst 416:209–215. https://doi.org/10.1080/15421400490481377

Aravinthan G, Kale DD (2005) Blends of poly (ethylene terephthalate) and poly (butylene terephthalate). J Appl Polym Sci 98:75–82. https://doi.org/10.1002/app.22017

Ito K, Haraguchi Y, Hayakawa S, Toda A (2008) Enhanced crystallization of blended poly (ethylene terephthalate) and poly (butylene terephthalate). Polym J 40:992. https://doi.org/10.1295/polymj.PJ2007197

Baxi RN, Pathak SU, Peshwe DR (2010) Mechanical, thermal, and structural characterization of poly (ethylene terephthalate) and poly (butylene terephthalate) blend systems by the addition of postconsumer poly (ethylene terephthalate). J Appl Polym Sci 115:928–934. https://doi.org/10.1002/app.30647

Marcinčin A, Körmendy E, Hricová M, Rusnák A, Aneja AP (2006) Rheologicalbehavior of polyester blend and mechanical properties of thepolypropylene–polyester blend fibers. J. Appl. Polym. Sci. 102(5):4222–4227. https://doi.org/10.1002/app.24682

Marcinčin A, Körmendy E, Hricová M, Rusnák A, Aneja AP (2006) Rheological behavior of polyester blend and mechanical properties of the polypropylene–polyester blend fibers. J Appl Polym Sci 102(5):4222–4227. https://doi.org/10.1002/app.24682

Stocco A, La Carrubba V, Piccarolo S, Brucato V (2009) The solidification behavior of a PBT/PET blend over a wide range of cooling rate. J Polym Sci Part B: Polym Phys 47(8):799–810. https://doi.org/10.1002/polb.21687

Kruse M, Wagner M (2016) Time-resolved rheometry of poly(ethylene terephthalate) during thermal and thermo-oxidative degradation. Rheol Acta 55(8):789–800. https://doi.org/10.1007/s00397-016-0955-2

Acknowledgements

The authors would like to acknowledge the financial supports from Istanbul Technical University Scientific Research Project (ITU-BAP) with the project number of 42102. We thank Arçelik A.Ş. and Hazal Oguz for kindly providing us the materials used in this study. The authors would also like to sincerely thank Professor Seniha Fatma Guner and Professor Gurbuz Gunes for providing us their laboratory space to perform rheological and compression molding experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guclu, M., Alkan Göksu, Y., Özdemir, B. et al. Thermal Stabilization of Recycled PET Through Chain Extension and Blending with PBT. J Polym Environ 30, 719–727 (2022). https://doi.org/10.1007/s10924-021-02238-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02238-8