Abstract

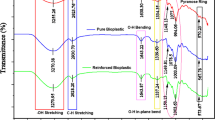

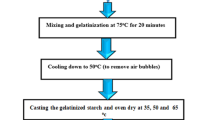

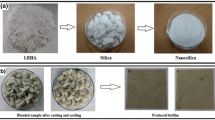

In the present study, 0.5–1.5% silica powder, from sugarcane waste ash, was incorporated into corn and potato starch bioplastics doped with sodium silicate solution to improve the properties of elongation at break and increase the thermal resistance of the bioplastics. The starch-based bioplastics were produced by casting and characterized by color analyses, transparency, opacity apparent, humidity, thickness, tensile strength, elongation at break, FTIR, DSC, SEM, and biodegradation assay. The addition of 0.5% of silica powder improved the elongation at break of the corn starch-based bioplastics. The sample CS5-P0.5 presented the highest percentage of elongation at the break among the studied samples, increased from 59.2% (without silica powder) to 78.9% (with silica powder). For potato starch bioplastic the addition of 0.5% of silica powder did not improve elongation at break but increased the thermal resistance. Increased until 17 °C for PS5-P0.5 sample and until 11 °C for PS7.5-P0.5 sample. The bioplastics of potato starch were biodegraded in 5 days, and those of corn starch took almost 40 days. Silica powder inhibited the growth of fungi in starch bioplastics.

Graphic Abstract

Similar content being viewed by others

References

Ghayebzadeh M, Aslani H, Taghipour H, Mousavi S (2020) Estimation of plastic waste inputs from land into the Caspian Sea: a significant unseen marine pollution. Mar Pollut Bull 151:110871

Jambeck JR, Geyer R, Wilcox C, Siegler TR, Perryman M, Andrady A et al (2015) Plastic waste inputs from land into the ocean. Science 347(6223):768

Andrady AL (2017) The plastic in microplastics: A review. Mar Pollut Bull 119(1):12–22

Gonçalves de Moura I, Vasconcelos de Sá A, Lemos Machado Abreu AS, Alves Machado AV (2017) 7—Bioplastics from agro-wastes for food packaging applications. In: Grumezescu AM (ed) food packaging. Academic Press, New York, pp 223–263

Zhang R, Wang X, Cheng M (2018) Preparation and characterization of potato starch film with various size of nano-SiO2. Polymers 10(10):1172

Bergel BF, da Luz LM, Santana RMC (2017) Comparative study of the influence of chitosan as coating of thermoplastic starch foam from potato, cassava and corn starch. Prog Org Coat 106:27–32

Podshivalov A, Zakharova M, Glazacheva E, Uspenskaya M (2017) Gelatin/potato starch edible biocomposite films: correlation between morphology and physical properties. Carbohydr Polym 157:1162–1172

Souza AC, Benze R, Ferrão ES, Ditchfield C, Coelho ACV, Tadini CC (2012) Cassava starch biodegradable films: influence of glycerol and clay nanoparticles content on tensile and barrier properties and glass transition temperature. LWT Food Sci Technol 46(1):110–117

Luchese CL, Spada JC, Tessaro IC (2017) Starch content affects physicochemical properties of corn and cassava starch-based films. Ind Crops Prod 109:619–626

Wang C-z, Li F-y, Wang L-m, Li J-f, Guo A-f, Zhang C-w et al (2015) Research on thermoplastic starch and different fiber reinforced biomass composites. RSC Adv 5(62):49824–49830

Luchese CL, Frick JM, Patzer VL, Spada JC, Tessaro IC (2015) Synthesis and characterization of biofilms using native and modified pinhão starch. Food Hydrocoll 45:203–210

Abral H, Soni Satria R, Mahardika M, Hafizulhaq F, Affi J, Asrofi M et al (2019) Comparative study of the physical and tensile properties of Jicama (Pachyrhizus erosus) starch film prepared using three different methods. Starch Stärke 71(5–6):1800224

Domene-López D, Delgado-Marín JJ, Martin-Gullon I, García-Quesada JC, Montalbán MG (2019) Comparative study on properties of starch films obtained from potato, corn and wheat using 1-ethyl-3-methylimidazolium acetate as plasticizer. Int J Biol Macromol 135:845–854

Dai L, Zhang J, Cheng F (2019) Effects of starches from different botanical sources and modification methods on physicochemical properties of starch-based edible films. Int J Biol Macromol 132:897–905

Santana RF, Bonomo RCF, Gandolfi ORR, Rodrigues LB, Santos LS, dos Santos Pires AC et al (2018) Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol. J Food Sci Technol 55(1):278–286

Zhong Y, Godwin P, Jin Y, Xiao H (2020) Biodegradable polymers and green-based antimicrobial packaging materials: a mini-review. Adv Ind Eng Polym Res 3(1):27–35

Zhao X, Cornish K, Vodovotz Y (2020) Narrowing the gap for bioplastic use in food packaging: an update. Environ Sci Technol 54(8):4712–4732

Yao K, Cai J, Liu M, Yu Y, Xiong H, Tang S et al (2011) Structure and properties of starch/PVA/nano-SiO2 hybrid films. Carbohydr Polym 86(4):1784–1789

Ghazihoseini S, Alipoormazandarani N, Nafchi AM (2015) The effects of nano-SiO2 on mechanical, barrier, and moisture sorption isotherm models of novel soluble soybean polysaccharide films. Int J Food Eng 11(6):833

Wu M, Wang M, Ge M (2009) Investigation into the performance and mechanism of SiO2 nanoparticles and starch composite films. J Text Inst 100(3):254–259

Datta D, Halder G (2019) Effect of rice husk derived nanosilica on the structure, properties and biodegradability of corn-starch/LDPE composites. J Polym Environ 27(4):710–727

de Azevedo LC, Rovani S, Santos JJ, Dias DB, Nascimento SS, Oliveira FF et al (2020) Biodegradable films derived from corn and potato starch and study of the effect of silicate extracted from sugarcane waste ash. ACS Appl Polym Mater 2(6):2160–2169

Rovani S, Santos JJ, Corio P, Fungaro DA (2018) Highly pure silica nanoparticles with high adsorption capacity obtained from sugarcane waste ash. ACS Omega 3(3):2618–2627

Rovani S, Santos JJ, Corio P, Fungaro DA (2019) An alternative and simple method for the preparation of bare silica nanoparticles using sugarcane waste ash, an abundant and despised residue in the Brazilian industry. J Braz Chem Soc 30:1524–1533

Alves RH, da Silva Reis TV, Rovani S, Fungaro DA (2017) Green synthesis and characterization of biosilica produced from sugarcane waste ash. J Chem 2017:1–9

Maeda EA, Santos AF, Silva LGA, Schön CG (2016) Chemical, physical, and mechanical properties evolution in electron beam irradiated isotactic polypropylene. Mater Chem Phys 169:55–61

Dang KM, Yoksan R (2015) Development of thermoplastic starch blown film by incorporating plasticized chitosan. Carbohydr Polym 115:575–581

El Miri N, Abdelouahdi K, Barakat A, Zahouily M, Fihri A, Solhy A et al (2015) Bio-nanocomposite films reinforced with cellulose nanocrystals: rheology of film-forming solutions, transparency, water vapor barrier and tensile properties of films. Carbohydr Polym 129:156–167

Rocha GO, Farias MG, Carvalho CWP, Ascheri JLR, Galdeano MC (2014) Filmes compostos biodegradáveis a base de amido de mandioca e proteína de soja. Polimeros 24:587–595

Thomas RJ, Asakawa NM (1993) Decomposition of leaf litter from tropical forage grasses and legumes. Soil Biol Biochem 25(10):1351–1361

Rezende CdP, Cantarutti RB, Braga JM, Gomide JA, Pereira JM, Ferreira E et al (1999) Litter deposition and disappearance in Brachiaria pastures in the Atlantic Forest Region of the South of Bahia, Brazil. Nutr Cycl Agroecosyst 54(2):99–112

Coelho CCS, Silva RBS, Carvalho CWP, Rossi AL, Teixeira JA, Freitas-Silva O et al (2020) Cellulose nanocrystals from grape pomace and their use for the development of starch-based nanocomposite films. Int J Biol Macromol 159:1048–1061

Kalapathy U, Proctor A, Shultz J (2000) Silica xerogels from rice hull ash: structure, density and mechanical strength as affected by gelation pH and silica concentration. J Chem Technol Biotechnol 75(6):464–468

Kalapathy U, Proctor A, Shultz J (2000) A simple method for production of pure silica from rice hull ash. Bioresour Technol 73(3):257–262

Jansson A, Thuvander F (2004) Influence of thickness on the mechanical properties for starch films. Carbohydr Polym 56(4):499–503

Luchese CL, Benelli P, Spada JC, Tessaro IC (2018) Impact of the starch source on the physicochemical properties and biodegradability of different starch-based films. J Appl Polym Sci 135(33):46564

Bertuzzi MA, Armada M, Gottifredi JC (2007) Physicochemical characterization of starch based films. J Food Eng 82(1):17–25

Wu J-H, Yen M-S, Kuo MC, Chen B-H (2013) Physical properties and crystallization behavior of silica particulates reinforced poly(lactic acid) composites. Mater Chem Phys 142(2):726–733

Wu J-H, Chen C-W, Kuo MC, Yen M-S, Lee K-Y (2018) High toughness and fast crystallization poly(lactic acid)/polyamide 11/SiO2 composites. J Polym Environ 26(2):626–635

Basiak E, Lenart A, Debeaufort F (2017) Effect of starch type on the physico-chemical properties of edible films. Int J Biol Macromol 98:348–356

Pankaj SK, Bueno-Ferrer C, Misra NN, O’Neill L, Tiwari BK, Bourke P et al (2015) Dielectric barrier discharge atmospheric air plasma treatment of high amylose corn starch films. LWT Food Sci Technol 63(2):1076–1082

Shi R, Liu Q, Ding T, Han Y, Zhang L, Chen D et al (2007) Ageing of soft thermoplastic starch with high glycerol content. J Appl Polym Sci 103(1):574–586

Boza AF, Kupfer VL, Oliveira AR, Radovanovic E, Rinaldi AW, Meneguin JG et al (2016) Synthesis of α-aminophosphonates using a mesoporous silica catalyst produced from sugarcane bagasse ash. RSC Adv 6(29):23981–23986

Wiącek AE (2015) Effect of surface modification on starch biopolymer wettability. Food Hydrocoll 48:228–237

Li J, Ye F, Liu J, Zhao G (2015) Effects of octenylsuccination on physical, mechanical and moisture-proof properties of stretchable sweet potato starch film. Food Hydrocoll 46:226–232

Ren L, Yan X, Zhou J, Tong J, Su X (2017) Influence of chitosan concentration on mechanical and barrier properties of corn starch/chitosan films. Int J Biol Macromol 105(Pt 3):1636–1643

Fahrngruber B, Fortea-Verdejo M, Wimmer R, Mundigler N (2020) Starch/poly(butylene succinate) compatibilizers: effect of different reaction-approaches on the properties of thermoplastic starch-based compostable films. J Polym Environ 28(1):257–270

Capeletti LB, de Oliveira LF, de Almeida Goncalves K, de Oliveira JF, Saito A, Kobarg J et al (2014) Tailored silica-antibiotic nanoparticles: overcoming bacterial resistance with low cytotoxicity. Langmuir 30(25):7456–7464

Derbalah A, Shenashen M, Hamza A, Mohamed A, El Safty S (2019) Antifungal activity of fabricated mesoporous silica nanoparticles against early blight of tomato. Egypt J Basic Appl Sci 5(2):145–150

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brazil (CAPES)—Finance Code 001, in part by the Conselho Nacional de Desenvolvimento Científico e Tecnológico—Brazil (CNPq), and in part by the Fundação de Amparo à Pesquisa do Estado de São Paulo—Brazil (FAPESP). The authors also are grateful to COSAN S.A. (São Paulo, Brazil) for supplying the sugarcane waste ash, the Dra. Paola Corio who made the Spectrometer from Bruker to collect FTIR-ATR spectra available.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

de Azêvedo, L.C., Rovani, S., Santos, J.J. et al. Study of Renewable Silica Powder Influence in the Preparation of Bioplastics from Corn and Potato Starch. J Polym Environ 29, 707–720 (2021). https://doi.org/10.1007/s10924-020-01911-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01911-8