Abstract

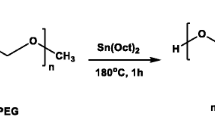

Ring opening copolymerization is the most frequently applied reaction for the synthesis of polycaprolactone–polyethylene glycol–polycaprolactone (PCL–PEG–PCL). In this reaction, a number of expensive and toxic organic solvents are being used for the purpose of purification and extraction of the prepared copolymer. Exposure to these organic solvents can cause serious issues to the human health and also impart serious environmental pollution. In the current work, a new, economical and organic solvent free approach was used for the synthesis of triblock copolymer. The results of the current studies confirmed the successful formation of triblock copolymer as revealed by Fourier transform infrared spectra, 13carbon nuclear magnetic resonance (13C-NMR) and proton nuclear magnetic resonance (1H-NMR). Gel permeation chromatography analysis ensured the homo-distribution of the prepared copolymer. The prepared copolymer was further evaluated as a carrier for the drug loading. Nanomicelles were successfully prepared by the nanoprecipitation technique and exhibited an average size distribution of 42.50 nm and an encapsulation efficiency of 90%. The prepared nanomicelles also exhibited safety at the concentration of 50 µg/ml and a long-term storage stability. All these studies suggested the success of the new simplest and economical method for the synthesis of PCL–PEG–PCL and its subsequent applications as a carrier for fabrication and efficient delivery of hydrophobic drug molecules.

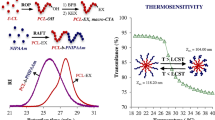

Graphic Abstract

Similar content being viewed by others

References

Cabral H, Miyata K, Osada K, Kataoka K (2018) Chem Rev 14:6844–6892

Youn YS, Bae YH (2018) Adv Drug Deliv Rev 130:3–11

Hacker MC, Krieghoff J, Mikos AG (2019) Synthetic polymers. In: Principles of regenerative medicine. Elsevier, New York

Cheng H (2012) An overview of degradable polymers. Degradable polymers and materials: principles and practice. ACS, Washington, DC

Terzopoulou Z, Klonos PA, Kyritsis A, Tziolas A, Avgeropoulos A, Papageorgiou GZ, Bikiaris DN (2019) Polymer 11:1–12

Ganipineni LP, Ucakar B, Joudiou N, Bianco J, Danhier P, Zhao M, Bastiancich C, Gallez B, Danhier F, Preat V (2018) Int J Nanomed 13:4509–4521

Badri W, El Asbahani A, Miladi K, Baraket A, Agusti G, Nazari QA, Errachid A, Fessi H, Elaissari A (2018) J Drug Deliv Sci Technol 3:234–242

Gupta B, Revagade N, Hilborn J (2007) Prog Polym Sci 4:455–482

Guarino V, Gentile G, Sorrentino L, Ambrosio L (2002) EPST 5:1–36

Azevedo M, Reis R, Claase M, Grijpma DW, Feijen J (2003) J Materials Sci Mater Med 2:103–107

Qindeel M, Ahmed N, Khan GM, Rehman AU (2019) Nanomedicine 14:1–20

Sabir F, Asad MI, Qindeel M, Afzal I, Dar MJ, Shah KU, Zeb A, Khan GM, Ahmed N, Din F-U (2019) J Nanomater 2019:1–16

Veronese FM (2005) Pasut G 21:1451–1458

Bunker A (2012) Phys Procedia 34:24–33

Bailon P, Won C-Y (2009) Expert Opin Drug Deliv 1:1–16

Lipka J, Semmler-Behnke M, Sperling RA, Wenk A, Takenaka S, Schleh C, Kissel T, Parak WJ, Kreyling WG (2010) Biomaterials 25:6574–6581

Gong C, Wei X, Wang X, Wang Y, Guo G, Mao Y, Luo F, Qian Z (2010) Nanotechnology 21:215103

Gong C, Shi S, Dong P, Kan B, Gou M, Wang X, Li X, Luo F, Zhao X, Wei Y (2009) Int J Pharm 1–2:89–99

Feng R, Song Z, Zhai G (2012) Int J Nanomed 7:4089

Pazarceviren E, Erdemli O, Keskin D, Tezcaner A (2017) J Biomater Appl 8:1148–1168

Mohanty AK, Jana U, Manna PK, Mohanta GP (2015) Prog Biomater 2–4:89–100

Zhou S, Deng X, Yang H (2003) Biomaterials 20:3563–3570

Pereira ADF, Pereira LGR, Barbosa LADO, Fialho SL, Pereira BG, Patricio PSDO, Pinto FCH, Da Silva GR (2013) Drug Deliv 3–4:168–179

Rostamizadeh K, Manafi M, Nosrati H, Manjili HK, Danafar H (2018) New J Chem 8:5937–5945

Zhang Y, Zhuo R (2005) Biomaterials 33:6736–6742

Liu CB, Gong CY, Huang MJ, Wang JW, Pan YF, Zhang YD, Li GZ, Gou ML, Wang K, Tu MJ (2008) J Biomed Mater Res B 1:165–175

Li R, Li X, Xie L, Ding D, Hu Y, Qian X, Yu L, Ding Y, Jiang X, Liu B (2009) Int J Pharm 1:158–166

Baker EL (1988) Annu Rev Public Health 1:223–232

Dick FD (2006) Occup Environ Med 3:221–226

Spencer PS, Schaumburg HH (1985) Scand J Work Environ Health 21:53–60

Seedorff L, Olsen E (1990) Ann Occup Hyg 4:371–378

Huang J, Kato K, Shibata E, Asaeda N, Takeuchi Y (1994) Nerve-specific marker proteins as indicators of organic solvent neurotoxicity. In Neurobehavioral methods and effects in occupational and environmental health. Elsevier, New York

Qindeel M, Ahmed N, Sabir F, Khan S, Ur-Rehman A (2019) Drug Dev Ind Pharm 4:629–641

Moya ML, Lopez-López M, Lebron JA, Ostos FJ, Perez D, Camacho V, Beck I, Merino-Bohorquez V, Camean M, Madinabeitia N (2019) Pharmaceutics 2:69

Begas E, Papandreou C, Tsakalof A, Daliani D, Papatsibas G, Asprodini E (2014) J Chromatogr Sci 7:590–595

Zhao J, Zhang X, Sun X, Zhao M, Yu C, Lee RJ, Sun F, Zhou Y, Li Y, Teng L (2018) Eur J Pharm Biopharm 12:39–47

Guney A, Gardiner C, McCormack A, Malda J, Grijpma D (2018) Bioengineering 4:99

Danafar H (2017) Jundishapur J Nat Pharm Prod 12:1

Piao L, Dai Z, Deng M, Chen X, Jing X (2003) Polymer 7:2025–2031

Hwang MJ, Suh JM, Bae YH, Kim SW, Jeong B (2005) Biomacromol 2:885–890

Alami-Milani M, Zakeri-Milani P, Valizadeh H, Salehi R, Jelvehgari M (2018) IJBMS 2:153

Brandt JV, Piazza RD, dos Santos CC, Vega-Chacon J, Amantea BE, Pinto GC, Magnani M, Piva HL, Tedesco AC, Primo FL (2019) Colloids Surf B 6:228–234

Dong P, Wang X, Gu Y, Wang Y, Wang Y, Gong C, Luo F, Guo G, Zhao X, Wei Y (2010) Colloids Surf A 1–3:128–134

Manjili HK, Malvandi H, Mousavi MS, Attari E, Danafar H (2018) Artif Cells Nanomed Biotechnol 5:926–936

Acknowledgements

The financial support to accomplish this research by Higher Education Commission of Pakistan is gratefully acknowledged. Maimoona Qindeel was supported by Indigenous Scholarship granted by Higher Education Commission of Pakistan. The authors also acknowledge Mr. Mulazim Hussain Asim for his help regarding chemicals. Department of Microbiology and Department of Chemistry, Quaid-i-Azam University is gratefully acknowledged for support in analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qindeel, M., Ahmed, N., Shah, K.U. et al. New, Environment Friendly Approach for Synthesis of Amphiphilic PCL–PEG–PCL Triblock Copolymer: An Efficient Carrier for Fabrication of Nanomicelles. J Polym Environ 28, 1237–1251 (2020). https://doi.org/10.1007/s10924-020-01683-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01683-1