Abstract

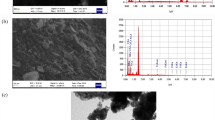

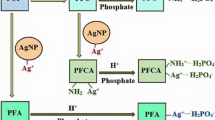

In this study, a novel polyurethane foam (PU) nanocomposite adsorbent based on silane-modified magnetic iron-oxide nanoparticles (Fe3O4@APTES) is synthesized via a low cost and simple in situ polymerization method for the removal of arsenic ions from aqueous solutions. The chemical structure and surface morphology of the prepared nanoparticles and adsorbent were characterized using Fourier transform infrared spectroscopy, attenuated total reflection, scanning electron microscopy, transmission electron microscopy, and energy-dispersive X-ray spectroscopy. Inductively coupled plasma mass spectrometry was used to measure the arsenic concentration of the treated solutions. Sorption isotherms models were applied to determine the adsorption mechanism and modeling parameters. The removal capacity of the modified PU foam was at its highest during a contact time of four hours which resulted in a removal capacity of 95%. Kinetic studies were conducted to determine the adsorption capacity and the uptake rate of arsenic. A Pseudo-order model was found to be the best fit model for adsorption. The prepared adsorbent can be separated from the solution by using an external magnet field.

Similar content being viewed by others

References

Kumar M, Puri A (2012) Indian J Occup Environ Med 16:40–44

Zhou S, Wang D, Sun H, Chen J, Wu S, Na P (2014) Water Air Soil Pollut 225:1945

Lièvremont D, Bertin PN, Lett MC (2009) Biochimie 91:1229–1237

Malwal D, Gopinath P (2017) Colloid Interface Sci Commun 19:14–19

Zhu J, Wei S, Chen M, Gu H, Rapole SB, Pallavkar S, Ho TC, Hopper J, Guo Z (2013) Adv Powder Technol 24:459–467

Venkateswarlu S, Kumar BN, Prathima B, SubbaRao Y, Jyothi NVV (2014) Arab J Chem. https://doi.org/10.1016/j.arabjc.2014.09.006

Wang J, Xu W, Chen L, Huang X, Liu J (2014) Chem Eng J 251:25–34

Musico YLF, Santos CM, Dalida MLP, Rodrigues DF (2013) J Mater Chem A 1:3789–3796

Yu X, Tong S, Ge M, Zuo J, Cao C, Song W (2013) J Mater Chem A 1:959–965

Sharma M, Kalita P, Garg A, Senapati K (2018) Ecol Environ Sci 8(3):207–210

Cao C, Xiao L, Chen C, Shi X, Cao Q, Gao L (2014) Powder Technol 260:90–97

Hussein FB, Abu-Zahra NH (2016) Water Sci Technol 17:889–896

Hussein FB, Abu-Zahra NH (2016) J Water Process Eng 13:1–5

Hussein FB, Abu-Zahra NHJ (2017) JMMCE 5:298–310

Moghaddam ST, Naimi-Jamal MR (2018) J Thermoplast Compos Mater. https://doi.org/10.1177/0892705718798008

Abu-Zahra N, Gunashekar S (2014) J Res Updates Polym Sci 3:16–25

Gunashekar S, Abu-Zahra N (2016) J Porous Mater 23:801–810

Gunashekar S, Abu-Zahra N (2014) Int J Polym Sci 2014:7

Pandey N, Shukla SK, Singh NB (2017) Nanocomposites 3:47–66

Zhu J, Wei S, Lee IY, Park S, Willis J, Haldolaarachchige N, Young DP, Luoe Z, Guo Z (2012) RSC adv 2:1136–1143

Yang K, Peng H, Wen Y, Li N (2010) Appl Surf Sci 256:3093–3097

Moghaddam ST, Naimi-Jamal MR (2017) 21st International Electronic Conference on Synthetic Organic Chemistry Sciforum

Zhou L, Li G, An T, Li Y (2010) Res Chem Intermed 36:277–288

Ramesh A, Hasegawa H, Maki T, Ueda K (2007) Sep Purif Technol 56:90–100

Gong J, Liu T, Wang X, Hu X, Zhang L (2011) Environ Sci Technol 45:6181–6187

Acknowledgement

The authors would like to thank Dr. Steven Hardcastle at UWM’s Advanced Analysis Facility and Dr. Ana Benko at UWM’s Shimadzu Lab Facility for their support and insights during the characterization and performance analysis of the foam samples.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tamaddoni Moghaddam, S., Naimi-Jamal, M.R., Rohlwing, A. et al. High Removal Capacity of Arsenic from Drinking Water Using Modified Magnetic Polyurethane Foam Nanocomposites. J Polym Environ 27, 1497–1504 (2019). https://doi.org/10.1007/s10924-019-01446-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01446-7