Abstract

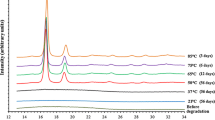

In this work, injection moulded hemp fibre reinforced polylactide bio-composites of different fibre contents (0, 10, 20 and 30 wt%) were subjected to accelerated weathering of 12 h cyclic exposures of UV-light at 60 °C, water spray and condensation at 50 °C for 8, 16, 32, 48 and 64 cycles to study the changes in properties such as crystallinity, tensile, flexural, plane-strain fracture toughness (\({K_{Ic}}\)) and strain energy release rate (\({G_{Ic}}\)). The crystallinity of neat polylactide (PLA) was found to increase up to 50.6% after 64 cycles, whereas the crystallinity of composites of different fibre contents was found to increase in the range of 30.6 to 34.5% for 8 to 64 cycles. The overall mechanical properties (tensile, flexural, \({K_{Ic}}\) and \({G_{Ic}}\)) of the composites decreased as the number of cycles increased from 8 to 64. The crystallinity and the residual tensile strength, tensile modulus, tensile strain, \({K_{Ic}}\) and \({G_{Ic}}\) of the composites of 20 wt% fibres were found to be the highest after 64 cycles. In contrast, the residual flexural strength and flexural modulus of the composites of 30 wt% fibres were found to be the maximum after 64 cycles. Absorption of water, destruction of fibre integrity, degradation of PLA matrix, formation of cracks and pores were found to be the main causes of reduction in the mechanical properties of PLA bio-composites.

Similar content being viewed by others

Data Availability

The datasets generated during the current study are available from the corresponding author upon request.

References

Madhavan Nampoothiri K, Nair NR, John RP (2010) Bioresour Technol 101:8493–8501

Ho K-LG, Pometto AL, Hinz PN (1999) J Environ Polym Degrad 7:83–92

Li S, McCarthy S (1999) Macromolecules 32:4454–4456

Carrasco F, Pagès P, Gámez-Pérez J, Santana OO, Maspoch ML (2010) Polym Degrad Stabil 95:116–125

Lee SH, Kim IY, Song WS (2014) Macromol Res 22:657–663

Mitchell MK, Hirt DE (2015) Polym Eng Sci 55:1652–1660

Xu L, Crawford K, Gorman CB (2011) Macromolecules 44:4777–4782

Ndazi BS, Karlsson S (2011) eXPRESS Polym Lett 5:119–131

Owen KL (2013) Control of microstructure in poly-lactic acid and the effect on biodegradation. University of Birmingham, Birmingham

Bax B, Müssig J (2008) Compos Sci Technol 68:1601–1607

Plackett D, Løgstrup Andersen T, Batsberg Pedersen W, Nielsen L (2003) Compos Sci Technol 63:1287–1296

Lee S-H, Ohkita T, Kitagawa K (2004) Holzforschung 58:529–536

Mathew AP, Oksman K, Sain M (2005) J Appl Polym Sci 97:2014–2025

Wong S, Shanks R (2008) Compos Interfaces 15:131–145

Sawpan MA, Pickering KL, Fernyhough A (2011) Composites Part A 42:310–319

Pozo Morales A, Güemes A, Fernandez-Lopez A, Carcelen Valero V, De La Rosa Llano S (2017) Materials 10:1286

Gunti R, Prasad AVR, Gupta AVSSKS (2018) Polym Compos 39:1125–1136

Asaithambi B, Ganesan G, Ananda Kumar S (2014) Fibers Polym 15:847–854

Spiridon I, Darie RN, Kangas H (2016) Composites Part B 92:19–27

Graupner N, Müssig J (2017) Int J Polym Sci 2017:1–10

Cichorek M, Piorkowska E, Krasnikova N (2017) J Polym Environ 25:74–80

Wang F, Zhou S, Yang M, Chen Z, Ran S (2018) Polymers 10:401

Shahruddin M, Muhamad F, Zaleha M (2017) IOP Conf Ser Mater Sci Eng 165:012021

Islam MS, Pickering KL, Foreman NJ (2010) Polym Degrad Stabil 95:59–65

Azwa ZN, Yousif BF, Manalo AC, Karunasena W (2013) Mater Des 47:424–442

Siakeng R, Jawaid M, Ariffin H, Sapuan SM (2018) IOP Conf Ser Mater Sci Eng 290:012031

Junpeng D, Hongwu W, Wuchang F, Mingyang H (2018) Polym Compos 39:E188–E199

Baghaei B, Skrifvars M (2016) Composites Part A 81:139–144

Fang W, Mengqing Y, Shujue Z, Siyan R, Junqian Z (2018) J Appl Polym Sci 135:46148

Baghaei B, Skrifvars M, Berglin L (2013) Composites Part A 50:93–101

Yu T, Ren J, Li S, Yuan H, Li Y (2010) Composites Part A 41:499–505

van den Oever MJA, Beck B, Müssig J (2010) Composites Part A 41:1628–1635

Baghaei B, Skrifvars M, Salehi M, Bashir T, Rissanen M et al (2014) Composites Part A 61:1–12

Lee B-H, Kim H-S, Lee S, Kim H-J, Dorgan JR (2009) Compos Sci Technol 69:2573–2579

Le Duigou A, Davies P, Baley C (2009) Polym Degrad Stabil 94:1151–1162

Siengchin S, Dangtungee R (2013) J Thermoplas Compos Mater 26:1424–1440

Gil-Castell O, Badia JD, Kittikorn T, Strömberg E, Martínez-Felipe A et al (2014) Polym Degrad Stabil 108:212–222

Hu R-H, Sun M-y, Lim J-K (2010) Mater Des 31:3167–3173

Kaynak C, Dogu B (2016) Int Polym Proc 31:410–422

Mehta G, Mohanty AK, Drzal LT, Kamdem DP, Misra M (2006) J Polym Environ 14:359–368

Beg MDH, Pickering KL (2008) Polym Degrad Stabil 93:1939–1946

Pickering KL, Sawpan MA, Jayaraman J, Fernyhough A (2011) Composites Part A 42:1148–1156

Mathew AP, Kristiina O, Mohini S (2006) J Appl Polym Sci 101:300–310

Paul MA, Delcourt C, Alexandre M, Degée P, Monteverde F et al (2005) Polym Degrad Stabil 87:535–542

Adam F, Sushant A, Rakesh G (2016) J Appl Polym Sci 133:44166

Felfel RM, Hossain KMZ, Parsons AJ, Rudd CD, Ahmed I (2015) J Mater Sci 50:3942–3955

Gonzalez MF, Ruseckaite RA, Cuadrado TR (1999) J Appl Polym Sci 71:1223–1230

Sawpan MA, Pickering KL, Fernyhough A (2011) Composites Part A 42:888–895

Mwaikambo LY, Ansell MP (2006) J Mater Sci 41:2483–2496

Moyeenuddin AS (2016) Polym Compos 37:3181–3190

Tabi T, Sajo IE, Szabo F, Luyt AS, Kovacs JG (2010) eXPRESS Polym Lett 4:659–668

Zhang J, Tashiro K, Tsuji H, Domb AJ (2008) Macromolecules 41:1352–1357

Ass BAP, Belgacem MN, Frollini E (2006) Carbohydr Polym 63:19–29

Abbate dSF, Cristina VIG, Inês BTM (2017) Polym Eng Sci 57:464–472

Gardette M, Thérias S, Gardette J-L, Murariu M, Dubois P (2011) Polym Degrad Stabil 96:616–623

Bocchini S, Frache A (2013) eXPRESS Polym Lett 7:431–442

Elsawy MA, Kim K-H, Park J-W, Deep A (2017) Renew Sust Energ Rev 79:1346–1352

Hakkarainen M, Albertsson A-C, Karlsson S (1996) Polym Degrad Stabil 52:283–291

Renouf-Glauser AC, Rose J, Farrar DF, Cameron RE (2005) Biomaterials 26:5771–5782

Chaochanchaikul K, Jayaraman K, Rosarpitak V, Sombatsompop PDN (2011) Bioresources 7:38–55

Santos RB, Hart P, Jameel H, Chang H-m (2013) Bioresources 8:1478–1507

Delabarde C, Plummer CJG, Bourban P-E, Månson J-AE (2011) Polym Degrad Stabil 96:595–607

Guralp O, Sebnem K (2009) J Appl Polym Sci 114:2481–2487

Sair S, Oushabi A, Kammouni A, Tanane O, Abboud Y et al (2018) Case Stud Constr Mater 8:203–212

Thwe MM, Liao K (2003) Compos Sci Technol 63:375–387

Sawpan MA, Pickering KL, Fernyhough A (2012) Composites Part A 43:519–526

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahmad Sawpan, M., Islam, M.R., Beg, M.D.H. et al. Effect of Accelerated Weathering on Physico-Mechanical Properties of Polylactide Bio-Composites. J Polym Environ 27, 942–955 (2019). https://doi.org/10.1007/s10924-019-01405-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01405-2