Abstract

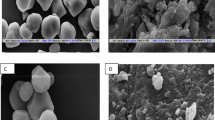

Modification of useful starch extracted from waste sorghum grains was carried out for production of superabsorbent materials which can be used in personal care products. Starch was extracted using alkali steeping method. It was characterized for swelling power, percentage transmittance and iodine binding values. The extracted starch was modified via graft copolymerization of acrylic acid and acrylamide onto starch to produce biodegradable absorbent material. The changes in modified starch structure were assessed using TGA, FTIR and SEM. The evaluation of enhancement in the properties was done by performing absorption tests. The reaction parameters were optimized to achieve higher graft add-on level and water absorption capacity. The absorbent product was further subjected to saponification for further enhancing its water absorption capacity (368.8 g/g). The product prepared by using optimized parameters of reaction was made highly porous by introducing sodium bicarbonate during the reaction. It showed a significant increase in the rate of water absorption and enhancement in water absorption capacity (380.9 g/g).The modified product showed 101.1 and 77.0 g/g absorption of artificial blood and artificial urine, respectively. This modified product was infused in commercially available sanitary napkin and baby diaper. Further, it was tested for fluid absorption and centrifuge retention capacity and it performed distinctly better than the commercial products. This superabsorbent material showed 12% weight loss after 28 days when biodegradability test by soil burial method was carried out.

Similar content being viewed by others

References

Brown PR, McWilliam A, Khamphoukeo K (2013) Post-harvest damage to stored grain by rodents in village environments in Laos. Int Biodeterior Biodegrad 82:104–109. doi:10.1016/j.ibiod.2012.12.018

Teli MD, Waghmare NG (2009) Synthesis of superabsorbent from carbohydrate waste. Carbohydr Polym 78:492–496. doi:10.1016/j.carbpol.2009.05.006

Parfitt J, Barthel M, Macnaughton S (2010) Food waste within food supply chains: quantification and potential for change to 2050. Philos Trans R Soc B 365:3065–3081. doi:10.1098/rstb.2010.0126

Buffo RA, Weller CL, Parkhurst AM (1998) Relationships among grain sorghum quality factors. Cereal Chem 75:100–104

Udachan IS, Sahu AK, Hend FM (2012) Extraction and characterization of sorghum (Sorghum bicolor L. Moench) starch. Int Food Res J 19:315–319

Zheng Y, Gao T, Wang A (2008) Preparation, swelling, and slow-release characteristics of superabsorbent composite containing sodium humate. Ind Eng Chem Res 47:1766–1773. doi:10.1021/ie0713137

Liu M, Liang R, Zhan F et al (2007) Preparation of superabsorbent slow release nitrogen fertilizer by inverse suspension polymerization. Polym Int 56:729–737. doi:10.1002/pi.2196

Parvathy PC, Jyothi AN, John KS, Sreekumar J (2014) Cassava starch based superabsorbent polymer as soil conditioner: impact on soil physico-chemical and biological properties and plant growth. CLEAN Soil Air Water 42:1610–1617. doi:10.1002/clen.201300143

Qiao D, Liu H, Yu L et al (2016) Preparation and characterization of slow-release fertilizer encapsulated by starch-based superabsorbent polymer. Carbohydr Polym 147:146–154. doi:10.1016/j.carbpol.2016.04.010

Teli MD, Mallick A (2015) Modification of Sorghum Starch for Production of Superabsorbents. Int Res J Eng Technol 2:442–448

Parvathy PC, Jyothi AN (2012) Synthesis, characterization and swelling behaviour of superabsorbent polymers from cassava starch-graft-poly(acrylamide). Starch Stärke 64:207–218. doi:10.1002/star.201100077

Zohuriaan-Mehr MJ, Kabiri K (2008) Superabsorbent polymer materials: a review. Iran Polym J 17:451–477

Wu JH, Wei YL, Lin JM, Lin SB (2003) Preparation of a starch-graft-acrylamide/kaolinite superabsorbent composite and the influence of the hydrophilic group on its water absorbency. Polym Int 52:1909–1912. doi:10.1002/pi.1303

Lanthong P, Nuisin R, Kiatkamjornwong S (2006) Graft copolymerization, characterization, and degradation of cassava starch-g-acrylamide/itaconic acid superabsorbents. Carbohydr Polym 66:229–245. doi:10.1016/j.carbpol.2006.03.006

Mohammed AD, Young DA, Vosloo HCM (2014) Synthesis and study of superabsorbent properties of acryloylated starch ester grafted with acrylic acid. Starch Stärke 66:393–399. doi:10.1002/star.201300174

Pourjavadi A, Barzegar S (2009) Synthesis and evaluation of pH and thermosensitive pectin-based superabsorbent hydrogel for oral drug delivery systems. Starch Stärke 61:161–172. doi:10.1002/star.200800063

Wei Q (2014) Fast-swelling porous starch-g-poly(acrylic acid) superabsorbents. Iran Polym J 23:637–643. doi:10.1007/s13726-014-0257-4

Chen J, Park H, Park K (1998) Synthesis of superporous hydrogels: Hydrogels with fast swelling and superabsorbent properties. J Biomed Mater Res 44:53–62. doi:10.1002/(SICI)1097-4636(199901)

Teli MD, Sheikh J (2011) Rheological study of starch extracted from germinated and non-germinated maize vis-a-vis printing. Carbohydr Polym 86:897–902. doi:10.1016/j.carbpol.2011.05.040

Subramanian V, Hoseney RC, Bramel-cox P (1994) Shear thinning properties of sorghum and corn starches’. Cereal Chem 71:272–275

Bhosale R, Singhal R (2007) Effect of octenylsuccinylation on physicochemical and functional properties of waxy maize and amaranth starches. Carbohydr Polym 68:447–456. doi:10.1016/j.carbpol.2006.11.011

Juliano BO (1971) A Simplified assay for milled-rice amylose. Cereal Sci Today 16:334–340

Phang Y-N, Chee S-Y, Lee C-O, Teh Y-L (2011) Thermal and microbial degradation of alginate-based superabsorbent polymer. Polym Degrad Stab 96:1653–1661

Gautam N, Kaur I (2013) Soil burial biodegradation studies of starch grafted polyethylene and identification of Rhizobium meliloti therefrom. J Environ Chem Ecotoxicol 5:147–158. doi:10.5897/JECE09.022

Indian Standard (1993) SPECIFICATION FOR SANITARY NAPKINS. MHD 14: Hospital Planning. India

Martinez AW, Phillips ST (2007) Supporting information for patterned paper as a platform for inexpensive, low volume, portable bioassays. https://gmwgroup.harvard.edu/pubs/Supplemental/983.pdf

Teli MD, Mallick A, Warge V (2015) Studies in general acceptance and efficacy of baby diapers. J Text Assoc 76:9–14

Teli MD, Mallick A, Srivastava A (2015) Parameters of choice of sanitary napkins—a techno-commercial survey. J Text Assoc 76:235–242

Li Y, Li X, Zhou L et al (2004) Study on the synthesis and application of salt-resisting polymeric hydrogels. Polym Adv Technol 15:34–38. doi:10.1002/pat.444

Mudiyanselage TK, Neckers DC (2008) Highly absorbing superabsorbent polymer. J Polym Sci Part A 46:1357–1364

Schott H (1992) Swelling kinetics of polymers. J Macromol Sci Part B 31:1–9

Meng Y, Ye L (2017) Synthesis and swelling property of the starch-based macroporous superabsorbent. J Appl Polym Sci. doi:10.1002/app.44855

Parvathy PC, Jyothi AN (2012) Water sorption kinetics of superabsorbent hydrogels of saponified cassava starch-graft-poly(acrylamide). Starch Staerke 64:803–812. doi:10.1002/star.201200001

Mencer HJ, Gomzi Z (1994) Swelling kinetics of polymer-solvent systems. Eur Polym J 30:33–36. doi:10.1016/0014-3057(94)90229-1

Wilske B, Bai M, Lindenstruth B et al (2014) Biodegradability of a polyacrylate superabsorbent in agricultural soil. Environ Sci Pollut Res 21:9453–9460. doi:10.1007/s11356-013-2103-1

Acknowledgements

Authors are thankful to University Grant Commission, India for funding the project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no financial/commercial conflicts of interest. The authors alone are responsible for the content and writing of the paper.

Rights and permissions

About this article

Cite this article

Teli, M.D., Mallick, A. Utilization of Waste Sorghum Grain for Producing Superabsorbent for Personal Care Products. J Polym Environ 26, 1393–1404 (2018). https://doi.org/10.1007/s10924-017-1044-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1044-z