Abstract

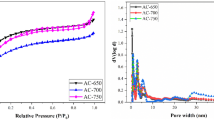

A one-step, facile method to produce 3-dimensional porous activated carbons (ACs) from corn residual dried distillers grains with solubles (DDGS) by microwave-assisted chemical activation was developed. The ACs’ application potentials in dye removal and supercapacitor electrodes were also demonstrated. The porous structure and surface properties of the ACs were characterized by N2 adsorption/desorption isotherms and scanning electron microscopy. The results showed that the surface area of the as-prepared ACs was up to 1000 m2/g. In the dye removal tests, these DDGS-based ACs exhibited a maximum adsorption ratio of 477 mg/g on methylene blue. In electric double layer capacitors, electrochemical tests indicated that the ACs had ideal capacitive and reversible behaviors and exhibited excellent electrochemical performance. The specific capacitance varied between 120 and 210 F/g under different scan rates and current densities. In addition, the capacitors showed excellent stability even after one thousand charge–discharge cycles. The specific capacitance was further increased up to 300 F/g by in situ synthesis of MnO2 particles in the ACs to induce pseudo-capacitance. This research showed that the DDGS-based ACs had great potentials in environmental remediation and energy storage applications.

Graphical Abstract

Similar content being viewed by others

References

Kim Y, Mosier NS, Hendrickson R et al (2008) Bioresour Technol 99:5165

Stein HH, Shurson GC (2009) J Anim Sci 87:1292

Wang X, Liang X, Wang Y et al (2011) Desalination 278:231

Sharma YC, Uma (2009) J Chem Eng Data 55:435

Berrios M, Martín MÁ, Martín A (2012) J Ind Eng Chem 18:780

Vijayaraghavan K, Balasubramanian R (2013) J Environ Chem Eng 1:473

Kötz R, Carlen M (2000) Electrochim Acta 45:2483

Zhang LL, Zhao XS (2009) Chem Soc Rev 38:2520

Maldhure AV, Ekhe JD (2011) Chem Eng J 168:1103

Yagmur E, Tunc MS, Banford A, Aktas Z (2013) J Anal Appl Pyrol 104:470

Foo KY, Hameed BH (2011) Bioresour Technol 102:9794

Foo KY, Hameed BH (2011) Chem Eng J 166:792

Zhao X-Y, Huang S-S, Cao J-P et al (2014) J Anal Appl Pyrol 105:116

Guo Y, Zhao J, Zhang H et al (2005) Dyes Pigm 66:123

Tan IAW, Ahmad AL, Hameed BH (2008) Chem Eng J 137:462

Deng H, Zhang G, Xu X, Tao G, Dai J (2010) J Hazard Mater 182:217

Jin H, Wang X, Gu Z (2013) Mater Focus 2:497

Hong J, Xiaomin W, Zhengrong G (2013) Mater Focus 2:105

Ioannidou O, Zabaniotou A (2007) Renew Sustain Energy Rev 11:1966

Bouchelta C, Medjram MS, Bertrand O, Bellat J-P (2008) J Anal Appl Pyrol 82:70

Zhong Z-Y, Yang Q, Li X-M, Luo K, Liu Y, Zeng G-M (2012) Ind Crops Prod 37:178

Horwitz W, Latimer GW (2005) Official methods of analysis of AOAC International. AOAC International, Gaithersburg

Figueroa-Gerstenmaier S, Bonet Avalos J, Gelb LD, Gubbins KE, Vega LF (2003) Langmuir 19:8592

Gañan J, González-García CM, González JF, Sabio E, Macías-García A, Díaz-Díez MA (2004) Appl Surf Sci 238:347

Rodriguez-Reinoso F, Martin-Martinez JM, Prado-Burguete C, McEnaney B (1987) J Phys Chem 91:515

Sevilla M, Parra JB, Fuertes AB (2013) ACS Appl Mater Interfaces 5:6360

Groen JC, Peffer LAA, Pérez-Ramírez J (2003) Micropor Mesopor Mater 60:1

Fu P, Hu S, Xiang J, Sun L, Su S, Wang J (2012) J Anal Appl Pyrol 98:177

Moreno AH, Arenillas A, Calvo EG, Bermúdez JM, Menéndez JA (2013) J Anal Appl Pyrol 100:111

Liu L, Lin Y, Liu Y, Zhu H, He Q (2013) J Chem Eng Data 58:2248

Boyd GE, Adamson AW, Myers LS (1947) J Am Chem Soc 69:2836

Wang S, Zhu ZH, Coomes A, Haghseresht F, Lu GQ (2005) J Colloid Interface Sci 284:440

Zhi M, Xiang C, Li J, Li M, Wu N (2013) Nanoscale 5:72

Prabaharan SRS, Vimala R, Zainal Z (2006) J Power Sources 161:730

Xu B, Wu F, Chen R et al (2008) Electrochem Commun 10:795

Wang D-W, Li F, Liu M, Lu GQ, Cheng H-M (2008) Angew Chem Int Ed 47:373

Lu W, Hartman R, Qu L, Dai L (2011) J Phys Chem Lett 2:655

Lei C, Amini N, Markoulidis F, Wilson P, Tennison S, Lekakou C (2013) J Mater Chem A 1:6037

Yan J, Fan Z, Wei T et al (2009) J Power Sources 194:1202

Jiang H, Li C, Sun T, Ma J (2012) Nanoscale 4:807

Huo H, Zhao Y, Xu C (2014) J Mater Chem A 2:15111

Wei D, Scherer MRJ, Bower C, Andrew P, Ryhänen T, Steiner U (2012) Nano Lett 12:1857

Wang G, Zhang L, Zhang J (2012) Chem Soc Rev 41:797

Toupin M, Brousse T, Bélanger D (2004) Chem Mater 16:3184

Wei W, Cui X, Chen W, Ivey DG (2011) Chem Soc Rev 40:1697

Jin X, Zhou W, Zhang S, Chen GZ (2007) Small 3:1513

Acknowledgments

The authors would like to thank Jessica Lattimer for the training of the microwave furnace and Drs. Yechun Wang and Qixin Zhou for their assistance to the EIS experiment. The authors also gratefully thank Guofeng Ren from Texas Tech University for helpful and enlightening discussion.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Funding

Research funds from North Dakota Corn Council and King Abdullah University of Science and Technology Baseline are greatly appreciated.

Conflict of interest

The authors declare no competing financial interest.

Rights and permissions

About this article

Cite this article

Wang, Y., Zhou, J., Jiang, L. et al. Development of Low-Cost DDGS-Based Activated Carbons and Their Applications in Environmental Remediation and High-Performance Electrodes for Supercapacitors. J Polym Environ 23, 595–605 (2015). https://doi.org/10.1007/s10924-015-0741-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-015-0741-8