Abstract

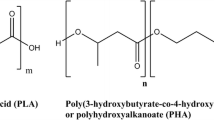

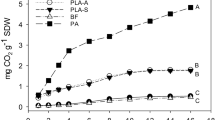

The effect of simulated weathering on the physicochemical properties and biodegradability of four fully biobased and potentially biodegradable agricultural mulches prepared nonwoven textile technology, consisting of randomly oriented fibers of average diameter 7–16 μm, has been investigated. Two mulches were prepared from polylactic acid (PLA) using spunbond processing, one naturally white and the other black (SB-W and SB-B, respectively), and two via meltblown processing, from 100 % PLA and a 75/25 w/w blend of PLA and polyhydroxyalkanoate [PHA; poly (3-hydroxybutyrate-co-4-hydroxybutyrate); MB-PLA and MB-PLA+PHA, respectively]. SB-W and SB-B possessed higher tensile strength than MB-PLA and MB-PLA+PHA (56.2N, 37.1N, 8.96N, and 3.90N, respectively). Simulated weathering introduced minor changes in physicochemical properties of SBs, but enhanced inherent biodegradability, yielding 68–72 % mineralization in 90 days. Simulated weathering greatly affected the physicochemical properties of the MB mulches, particularly MB-PLA+PHA, which underwent a 95 % loss of tensile strength, 32 % decrease of weight-averaged molecular weight (from 95.4 to 70.5 kDa), and breakage of microfibers, during a 21 days weatherometry cycle. Weathering accelerated the biodegradation of both MB mulches, with the time course of biodegradation and final extent of biodegradation (91–93 % in 90 days) nearly matching the value obtained for the cellulosic positive control. Fourier transform infrared spectroscopy suggested the SB and MB mulches underwent hydrolysis and photodegradative chain scission (Norrish Type II reaction). SB nonwovens may prove useful as biobased and compostable materials for multi-season mulching, and other long-term agricultural applications, such as for row covers in perennial cropping systems. MB nonwovens may be better suited for more traditional agricultural mulch applications.

Similar content being viewed by others

Abbreviations

- ATR:

-

Attenuated total reflectance

- BDMs:

-

Biodegradable mulches

- DSC:

-

Differential scanning calorimetry

- FTIR:

-

Fourier transform infrared spectroscopy

- GPC:

-

Gel permeation chromatography

- MB:

-

Meltblown (nonwoven materials)

- MD:

-

Machine direction

- Mw :

-

Weight-averaged molecular weight

- PDI:

-

Polydispersity index

- PHA:

-

Polyhydroxyalkanoate [poly(3-hydroxybutyrate-co-4-hydroxybutyrate]

- PLA:

-

Polylactic acid

- SB:

-

Spunbond (nonwoven materials)

- Tc :

-

Crystallization temperature

- Tg :

-

Glass transition temperature

- Tm :

-

Melting temperature

- UV:

-

Ultraviolet

References

Rudnik E, Briassoulis D (2011) Comparative biodegradation in soil behaviour of two biodegradable polymers based on renewable resources. J Polym Environ 19:18–39

Shogren RL, Hochmuth RC (2004) Field evaluation of watermelon grown on paper-polymerized vegetable oil mulches. HortScience 39:1588–1591

Kasirajan S, Ngouajio M (2012) Polyethylene and biodegradable mulches for agricultural applications: a review. Agron. Sustain. Dev. 32:501–529

Espi E, Salmeron A, Garcia Y, Real AIJ (2006) Plast. Film Sheeting 22:85–102

Lamont WJ Jr (2005) Plastics: modifying the microclimate for the production of vegetable crops. Hort Technol 15:477–481

Levitan L (2005) Reducing dioxin emissions by recycling agricultural plastics: Creating a viable alternative to open burning. In Great Lakes Regional Pollution Prevention Roundtable New York

Lemieux PM (1997) Evaluation of emissions from the open burning of household waste in barrels US Environmental Protection Agency Report 600/R-97-134a Washington, DC:70

Corbin AT, Miles C, Cowan J, Hayes DG, Moore-Kucera J, Inglis DA (2013) Current and Future Prospects For Biodegradable Plastic Mulch in Certified Organic Production Systems, eXtension Foundation,eOrganic Community of Practice:67951

Shogren RL (2000) Biodegradable Mulches from renewable resources. J. Sustain. Agric. 16:33–47

Gregory MR, Andrady AL (2005) Plastics in the marine environment. In: Andrady AL (ed) Plastics and the environment. Wiley, New York, pp 379–401

Martin-Closas L, Pelacho AM (2011) Agronomic potential of biopolymer films. in Plackett D (ed) Biopolymers—New Materials for Sustainable Films and Coatings John Wiley and Sons, Chichester, UK., pp. 277-299

Hayes DG, Dharmalingam S, Wadsworth LC, Leonas KK, Miles C, Inglis DA (2012) Biodegradable agricultural mulches derived from biopolymers. in Khemani K, Scholz C (eds) Degradable polymers and materials: principles and practice (2nd Edition), ACS Symposium Series, Vol.1114. American Chemical Society, Washington, DC, pp. 201–223

Briassoulis D (2006) Mechanical behavior of biodegradable agricultural films under real field conditions. Polym Degrad Stab 91:1256–1272

Briassoulis D (2007) Analysis of the mechanical and degradation performances of optimized agricultural biodegradable films. Polym Degrad Stab 92:1115–1132

Kijchavengkul T, Auras R, Rubino M, Ngouajio M, Fernandez RT (2008) Assessment of aliphatic–aromatic copolyester biodegradable mulch films. Part I: Field study. Chemosphere 71:942–953

Kijchavengkul T, Auras R, Rubino M, Ngouajio M, Fernandez RT (2008) Assessment of aliphatic–aromatic copolyester biodegradable mulch films. Part II: laboratory simulated conditions. Chemosphere 71:1607–1616

Mostafa H, Sourell H, Bockisch F (2010) Mechanical properties of some bioplastics under different soil types used as biodegradable drip tubes. CIGR J, Ag.Eng. Int., p 12

Siegenthaler KO, Künkel A, Skupin G, Yamamoto M (2012) Ecoflex® and Ecovio®: Biodegradable, Performance-Enabling Plastics. in Rieger B, Künkel A, Coates GW, Reichardt R, Dinjus E, Zevaco TA (eds) Synthetic Biodegradable Polymers (Advances in Polymer Science, Vol.245). Springer, Berlin, pp. 91–136

Tullo AH (2012) Old plastics, fresh dirt. Chem Eng News 90:12–18

Goldberger JR, Jones RE, Miles CA, Wallace RW, Inglis DA (2013) Barriers and bridges to the adoption of biodegradable plastic mulches for US specialty crop production. Renewable Agric. Food Sys., 1–11

Olsen JK, Gounder RK (2001) Alternatives to polyethylene mulch film—a field assessment of transported materials in capsicum (Capsicum annuum L.). Aust J Exp Agric 41:93–103

US Department of Agriculture (Agricultural marketing service) (2013) National organic program; proposed amendments to the national list of allowed and prohibited substances (crops and processing) (7 CFR part 205, document number AMS-NOP-13-011; NOP-13-01PR, RIN 0581-AD33). Fed Reg 78(163):52100–52107

Wadsworth LC, Hayes DG, Wszelaki AL, Washington TL, Martin J, Lee J, Raley R, Pannell CT, Dharmalingam S, Miles C, Inglis DA, Saxton AM (2012) Evaluation of degradable spun-melt 100% polylactic acid nonwovens mulch materials in a greenhouse envrionment. J. Eng. Fiber. Fabr. 8:50–59

Dugan JS (2001) Novel properties of PLA fibers. Int Nonwovens J 10:29–33

Feng S, Jiao X (2011) The application of PLA resin on nonwovens production, Adv. Mater. Res. (Durnten-Zurich, Switz.) 332–334:1239–1242

Li L, Zhang J, Li S, Qian X (2011) Research progress of elastic nonwovens with meltblown technology, Adv. Mater. Res. (Durnten-Zurich, Switz.) 332–334:1247–1252

Khan AYA, Wadsworth LC, Ryan CM (1995) Polymer-laid nonwovens from poly(lactide) resin. Int Nonwovens J 7:69–73

Endres H-J, Siebert-Raths A (2011) Engineering Biopolymers- Markets, Manufacturing. Hanser Publishers, Munich, Properties and Applications

Sodergard A, Stolt M (2010) Industrial production of high molecular weight poly(lactic acid). In: Auras R, Lim LT, Selke SEM, Tsuji H (eds) Poly(Lactic Acid): synthesis, structures, properties, processing, and applications. Wiley, Hoboken, pp 27–41

Tokiwa Y, Calabia BP, Ugwu CU, Aiba S (2009) Biodegradability of plastics. Int J Mol Sci 10:3722–3742

Hakkarainen M, Karlsson S, Albertsson AC (1999) Rapid (bio)degradation of polylactide by mixed culture of compost microorganisms-low molecular weight products and matrix changes. Polymer 41:2331–2338

Kawai F (2010) Polylactic Acid (PLA)-Degrading Microorganisms and PLA Depolymerases. in Cheng HN, Gross Richard A (eds) Green Polymer Chemistry: Biocatalysis and Biomaterials, ACS Symposium Series,Vol. 1043. American Chemical Society, Washington, DC, pp. 405–414

Weng Y-X, Wang L, Zhang M, Wang X-L, Wang Y-Z (2012) Biodegradation behavior of P (3HB, 4HB)/PLA blends in real soil environments. Polym. Test. 32:60–70

Ji XM, C.A., Martin, J.T., Wallace, R.W., Wszelaki, A.L., Moore-Kucera, J., Inglis, D.A., and Lee, J. (2013) Effect of biodegradable mulch on high tunnel and open field environments, J. Am.Soc.Hortic.Sci.:in press

Miles C, Wallace R, Wszelaki A, Martin J, Cowan J, Walters T, Inglis DA (2012) Deterioration of potentially biodegradable alternative to black plastic mulch in three tomato production regions. HortScience 47:1270–1277

Cowan JS (2013) The use of biodegradable mulch for tomato and broccoli production: Crop yield and quality, mulch deterioration, and growers’ perceptions. Washington State University, Pullman, p 225

Martin JT (2013) The Influence of organically managed high tunnel and open field production systems on strawberry (Fragaria x ananassa) quality and yield, tomato (Solanum lycopersicum) Yield, and evaluation of plastic mulch alternatives. Plant Science. Univesity of Tennessee, Knoxville, p. 128

Hussain I, Hamid H (2003) Plastics in Agriculture. In: Andrady AL (ed) Plastics and the environment. Wiley, New York, pp 185–209

Searle ND (2003) Environmental effects on polymeric materials. Wiley, New York

ASTM International (2013) standard practice for operating xenon arc light apparatus for exposure of non-metallic materials (ASTM G155). West Conshohocken, PA

ASTM International (2011) Standard test method for determining aerobic biodegradation of plastic materials under controlled composting conditions. Incorporating thermophilic temperatures (ASTM D5338). West Conshohocken, PA

ASTM International (2012) Standard specification for aerobically biodegradable plastics in soil environment (ASTM WK29802). West Conshohocken, PA

Saito Y, Doi Y (1994) Microbial synthesis and properties of poly (3-hydroxybutyrate-co-4-hydroxybutyrate) in Comamonas acidovorans. Int J Biol Macromol 16:99–104

Weng Y-X, Jin Y-J, Meng Q-Y, Wang L, Zhang M, Wang Y-Z (2013) Biodegradation behavior of poly(butylene adipate-co-terephthalate)(PBAT), poly(lactic acid) (PLA), and their blend under soil conditions. Polym. Test. 32:918–926

ASTM International (2004) Standard test method for thickness of nonwoven fabrics (ASTM D5729). West Conshohocken, PA

ASTM International (2009) Standard test methods for mass per unit area (weight) of fabric (ASTM D3776/D3776M-09aE2). West Conshohocken, PA

Cleveland WS, Grosse E, Shyu WM (1992) Local regression models. In: Chambers JM, Hastie TJ (eds) Statistical models in S. Wadsworth & Brooks, Cole, pp 309–376

R Development Core Team (2009) R: A Language and Environment for Statistical Computing. R Foundation for Statistical Computing, Vienna, Austria

Kijchavengkul T, Auras R (2008) Compostability of polymers. Polym Int 57:793–804

Garlotta D (2001) A literature review of poly(lactic acid). J Polym Environ 9:63–84

Ikada E (1997) Photodegradation behaviors of aliphatic polyesters. Photo-and bio-degradable polyesters. J. Photopolym. Sci. Technol 10:265Ā270

Grassie N, Murray E, Holmes P (1984) The thermal degradation of poly (-(D)-β-hydroxybutyric acid): part 1—identification and quantitative analysis of products. Polym Degrad Stab 6:47–61

Grassie N, Murray E, Holmes P (1984) The thermal degradation of poly (-(D)-β-hydroxybutyric acid): part 2—changes in molecular weight. Polym Degrad Stab 6:95–103

Grassie N, Murray E, Holmes P (1984) The thermal degradation of poly(-(D)-β-hydroxybutyric acid): part 3—The reaction mechanism. Polym Degrad Stab 6:127–134

Reddy CSK, Ghai R, Kalia VC (2003) Polyhydroxyalkanoates: an overview. Bioresour Technol 87:137–146

Lemoigne M (1926) Products of dehydration and of polymerization of β-hydroxybutyric acid. Bull. Soc. Chem. Biol. 8:770–782

Kim M-N, Lee A-R, Yoon J-S, Chin I-J (2000) Biodegradation of poly(3-hydroxybutyrate), Sky-Green and Mater-Bi by fungi isolated from soils. Eur. Polym. J. 36:1677–1685

Maiti P, Batt CA, Giannelis EP (2007) New biodegradable polyhydroxybutyrate/layered silicate nanocomposites. Biomacromolecules 8:3393–3400

ASTM International (2004) Standard specification for compostable plastics (ASTM D6400). West Conshohocken, PA

ASTM International (2011) Standard test method for determining aerobic biodegradation of plastic materials under controlled composting conditions (ASTM D5338). West Conshohocken, PA

ASTM International (2012) Standard specification for labeling of plastics designed to be aerobically composted in municipal or industrial facilities (ASTM D6400). West Conshohocken, PA

ASTM International (2011) Standard specification for labeling of end items that incorporate plastics and polymers as coatings or additives with paper and other substrates designed to be aerobically composted in municipal of industrial facilities (ASTM D6868). West Conshohocken, PA

Acknowledgments

This research was funded in part through a Grant from the NIFA Specialty Crops Research Initiative, USDA SCRI-SREP Grant Award No. 2009-02484. The authors are grateful to Natureworks (Blair, NE USA) and GreenBio (Tianjin, China) for donation of PLA (Ingeo™ 6202D) and PHA feedstocks, respectively. Ms. Rachel Dunlap, an undergraduate student research assistant at UT, assisted with the collection of GPC, dry weight, and thickness data. Drs. Debra Inglis and Carol Miles, Washington State University, and Dr. Arnold E. Saxton, UT, provided technical assistance relating to organic certification of biodegradable mulches, critically reviewed the manuscript, and advised on the statistical analysis of data, respectively.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Hablot, E., Dharmalingam, S., Hayes, D.G. et al. Effect of Simulated Weathering on Physicochemical Properties and Inherent Biodegradation of PLA/PHA Nonwoven Mulches. J Polym Environ 22, 417–429 (2014). https://doi.org/10.1007/s10924-014-0697-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-014-0697-0