Abstract

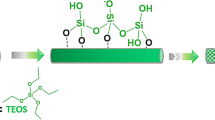

Bionanocomposites of poly(lactic acid) (PLA) and chemically modified, nanofibrillated cellulose (NFC) powders were prepared by extrusion, followed by injection molding. The chemically modified NFC powders were prepared by carboxymethylation and mechanical disintegration of refined, bleached beech pulp (c-NFC), and subsequent esterification with 1-hexanol (c-NFC-hex). A solvent mix was then prepared by precipitating a suspension of c-NFC-hex and acetone-dissolved PLA in ice-cold isopropanol (c-NFC-hexsm), extruded with PLA into pellets at different polymer/fiber ratios, and finally injection molded. Dynamic mechanical analysis and tensile tests were performed to study the reinforcing potential of dried and chemically modified NFC powders for PLA composite applications. The results showed a faint increase in modulus of elasticity of 10 % for composites with a loading of 7.5 % w/w of fibrils, irrespective of the type of chemically modified NFC powder. The increase in stiffness was accompanied by a slight decrease in tensile strength for all samples, as compared with neat PLA. The viscoelastic properties of the composites were essentially identical to neat PLA. The absence of a clear reinforcement of the polymer matrix was attributed to poor interactions with PLA and insufficient dispersion of the chemically modified NFC powders in the composite, as observed from scanning electron microscope images. Further explanation was found in the decrease of the thermal stability and crystallinity of the cellulose upon carboxymethylation.

Similar content being viewed by others

References

Auras R, Harte B, Selke S (2004) Macromol Biosci 4:835–864

Garlotta D (2001) J Polym Environ 9:63–84

Siro I, Plackett D (2010) Cellulose 17:459–494

Samir M, Alloin F, Dufresne A (2005) Biomacromolecules 6:612–626

Chazeau L et al (1999) J Appl Polym Sci 71:1797–1808

Favier V, Chanzy H, Cavaille JY (1995) Macromolecules 28:6365–6367

Marchessault RH, Morehead FF, Walter NM (1959) Nature 184:632–633

Turbak AF, Snyder FW, Sandberg KR (1983) J Appl Polym Sci Symp 37:815–827

Oksman K et al (2006) Compos Sci Technol 66:2776–2784

Mathew AP et al (2006) In: Oksman K, Sain M (eds) Cellulose nanocomposites: processing, characterization, and properties. American Chemical Society, Washington, pp 114–131

Petersson L, Kvien I, Oksman K (2007) Compos Sci Technol 67:2535–2544

Bondeson D, Oksman K (2007) Compos A Appl Sci Manuf 38:2486–2492

Bondeson D, Oksman K (2007) Compos Interfaces 14:617–630

Iwatake A, Nogi M, Yano H (2008) Compos Sci Technol 68:2103–2106

Suryanegara L, Nakagaito AN, Yano H (2009) Compos Sci Technol 69:1187–1192

Tingaut P, Zimmermann T, Lopez-Suevos F (2010) Biomacromolecules 11:454–464

Jonoobi M et al (2010) Compos Sci Technol 70:1742–1747

Eyholzer C et al (2010) Cellulose 17:19–30

Lee K-Y, Blaker JJ, Bismarck A (2009) Compos Sci Technol 69:2724–2733

Fukuzumi H et al (2009) Biomacromolecules 10:162–165

Leza ML et al (1989) Die Angewandte Makromolekulare Chemie 168:195–203

Rosenau T et al (2003) Polymer 44:6153–6158

Acknowledgments

The authors express their thanks to Aji Mathew and Maiju Hietala for their help during extrusion and injection molding, and Christian Walder (EMPA) for his support concerning the melt shear tests. The State Secretariat for Education and Research (SER) is gratefully acknowledged for the financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eyholzer, C., Tingaut, P., Zimmermann, T. et al. Dispersion and Reinforcing Potential of Carboxymethylated Nanofibrillated Cellulose Powders Modified with 1-Hexanol in Extruded Poly(Lactic Acid) (PLA) Composites. J Polym Environ 20, 1052–1062 (2012). https://doi.org/10.1007/s10924-012-0508-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-012-0508-4