Abstract

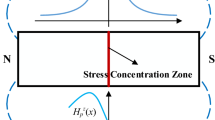

Giant magneto-resistive (GMR) sensor based metal magnetic memory (MMM) technique is proposed for mapping of deformation-induced self-magnetic leakage fields (SMLFs) in carbon steel. The specimens were subjected to different amounts of tensile deformation and the deformation-induced SMLFs were measured using a GMR sensor after unloading the specimens. 3D-nonlinear finite element modeling was performed to predict stress–strain state in a steel specimen under tensile load. The experimentally obtained SMLF images were correlated with the finite element model predicted stress–strain states. Studies reveal that the MMM technique can detect the plastic deformation with signal-to-noise ratio better than 20 dB. The technique enables the mapping of plastic deformation in carbon steels for the evaluation of the severity of deformation. The study also reveals that deformation-induced SMLF is influenced by the presence of initial surface residual stress, introduced by shot peening. The intensity of SMLF signal is found to increase with increase in tensile load and decrease with shot peening.

Similar content being viewed by others

References

Roskosz, M., Bieniek, M.: Analysis of the similarity between residual magnetic field distribution and the stress and strain state for 7CrMoVTiB10-10 (T/TP24) steel. Int. J. Appl. Electromagn. Mech. 39, 521–527 (2012)

Lei, H., Chen, Z., Li, Y., Takagi, T., Uchimoto, T., Chigusa, N., Yoshida, Y.: Dependence of deformation-induced magnetic field on plastic deformation for SUS304 stainless steel. Int. J. Appl. Electromagn. Mech. 38, 17–26 (2012)

Kupferlinga, M., Fiorilloa, F., Bassoa, V., Bertottia, G., Meilland, P.: Barkhausen noise in plastically deformed low-carbon steels. J. Magn. Magn. Mater. 320, 527–530 (2008)

Stupakov, O., Pala, J., Tomas, I., Bydzovsky, J., Novak, V.: Investigation of magnetic response to plastic deformation of low-carbon steel. Mater. Sci. Eng. A 462, 351–354 (2007)

Wang, P., Zhu, S., Tian, G.Y., Wang, H., Wilson, J., Wang, X.: Stress measurement using magnetic Barkhausen noise and metal magnetic memory testing. Meas. Sci. Technol. 21, 055703 (2010)

Singh, W.S., Stegemann, R., Kreutzbruck, M.: Three-dimensional finite element analysis of stress-induced geometry effect on self magnetic leakage fields during tensile deformation. Insight 58(10), 544–550 (2016)

Augustyniak, M., Usarek, Z.: Discussion of derivability of local residual stress level from magnetic stray field measurement. J. Nondestruct. Eval. 34, 21 (2015). https://doi.org/10.1007/s10921-015-0292-x

Wang, Z.D., Gu, Y., Wang, Y.S.: A review of three magnetic NDT technologies. J. Magn. Magn. Mater. 324, 382–388 (2012)

Doubov, A.A.: Diagnostics of equipment and constructions strength with usage of magnetic memory. Insp. Diagn. 6, 19 (2001)

Hu, B., Li, L., Chen, X., Zhong, L.: Study on the influencing factors of magnetic memory method. Int. J. Appl. Electromagn. Mech. 33, 1351–1357 (2010)

Changliang, S., Shiyun, D., Binshi, X., Peng, H.: Stress concentration degree affects spontaneous magnetic signals of ferromagnetic steel under dynamic tension load. NDT E Int. 43, 8–12 (2010)

Meng, L.X., Sheng, D.H., Wu, B.S.: Research on the stress-magnetism effect of ferromagnetic materials based on three-dimensional magnetic flux leakage testing. NDT E Int. 62, 50–54 (2014)

Huang, H., Jiang, S., Liu, R., Liu, Z.: Investigation of magnetic memory signals induced by dynamic bending load in fatigue crack propagation process of structural steel. J. Nondestruct. Eval. 33, 407–412 (2014)

Roskosz, M., Witos, M., Fryczowski, K.: Studies on magnetic and mechanical properties in plastically deformed ferromagnetic steels. Electromagn. Nondestruct. Eval. (XVII) 39, 271–279 (2014)

Usarek, Z., Augustyniak, B., Augustyniak, M., Chmielewski, M.: Influence of plastic deformation on stray magnetic field distribution of soft magnetic steel sample. IEEE Trans. Magn. 50(4), 7400104 (2014)

Singh, W.S., Rao, B.P.C., Mukhopadhyay, C.K., Jayakumar, T.: Detection of localized damage in water wall tubes of thermal power plants using GMR sensor array based magnetic flux leakage technique. J. Nondestruct. Eval. 34(3), 19 (2015). https://doi.org/10.1007/s10921-015-0295-7

Pelkner, M., Reimund, V., Erthner, T., Kreutzbruck, M.: Size adapted GMR arrays for the automated inspection of surface breaking cracks in roller bearings. Int. J. Appl. Electromagn. Mech. 45, 473–479 (2014)

Nikitin, I., Altenberger, I.: Comparison of the fatigue behaviour and residual stress stability of laser-sock peened and deep rolled austenitic stainless steel AISI 304 in the temperature range 25–600 \(^\circ \)C. Mater. Sci. Eng. A 465, 176–182 (1997)

Gurova, T., Teodosio, J.R., Rebello, J.M.A., Monin, V.: Study of the residual stress state during plastic deformation under uniaxial tension in a 5.0Cr and 0.5Mo steel. Scr. Mater. 36(9), 1031–1035 (1997)

DIN 50125:2009-07 Testing of Metallic Materials—Tensile Test Pieces. Beuth-Verlag, Berlin

ASM Handbook. Mechanical Testing and Evaluation, vol. 8. ASM International, Materials Park

ASM Handbook. Heat Treating, vol. 4. ASM International, Materials Park

ASTM E 709-01 Standard Guide for Magnetic Particle Examination. ASTM International, West Conshohocken (2001)

Dong, L., Xu, B., Dong, S., Song, L., Chen, Q., Wang, D.: Stress dependence of the spontaneous stray field signals of ferromagnetic steel. NDT E Int. 42, 323–327 (2009)

Makar, J.M., Tanner, B.K.: The effect of plastic deformation and residual stress on the permeability and magnetostriction of steels. J. Magn. Magn. Mater. 222(3), 291–304 (2000)

Torres, M.A.S., Voorwald, H.J.C.: An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 24, 877–886 (2002)

Acknowledgements

The authors would like to thank Mrs. N. Sonntag, BAM5.2, Berlin, Germany for carrying out tensile measurements and Dr. M. Pelkner, BAM 8.4, Berlin, Germany for fruitful technical discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, W.S., Stegemann, R., Kreutzbruck, M. et al. Mapping of Deformation-Induced Magnetic Fields in Carbon Steels Using a GMR Sensor Based Metal Magnetic Memory Technique. J Nondestruct Eval 37, 21 (2018). https://doi.org/10.1007/s10921-018-0470-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-018-0470-8