Abstract

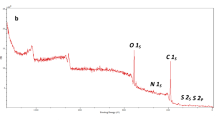

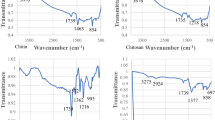

In this paper, crosslinking polymerization of chitosan with glutaraldehyde in the presence of zinc oxide nanoparticles was utilized for the synthesis of chitosan/glutaraldehyde/zinc oxide as a novel composite. The fabricated composite was characterized using some tools such as SEM, XRD, TGA, and BET. The successful formation of the chitosan/glutaraldehyde/zinc oxide composite was evidenced through the appearance of one broad XRD peaks at 2θ = 23.50°. Besides, the obvious destruction of the crystalline structure of zinc oxide has confirmed the successful formation of the composite. The FE-SEM images displayed that the surface of chitosan/glutaraldehyde/zinc oxide composite was wrinkled and rough, while the chitosan was dense and smooth, indicating important change in the morphology of the chitosan/glutaraldehyde/zinc oxide composite owing to the crosslinking of glutaraldehyde with chitosan and incorporation of ZnO. The BET surface area, average pore radius, and total pore volume of the chitosan/glutaraldehyde/zinc oxide composite are 32.50 m2/g, 39.36 Å, and 0.06 cc/g, respectively. The synthesized composite was operated for the efficient removal of eriochrome black T dye from aqueous media where its adsorption capacity is 1201.42 mg/g. The adsorption process of eriochrome black T dye obeys the Langmuir isotherm and pseudo-second-order model. Also, the adsorption process of eriochrome black T dye is endothermic, chemical, and spontaneous. The analytical influences that achieved the highest % removal of eriochrome black T dye are observed at pH 2, contact time = 140 min, and temperature = 318 K.

Similar content being viewed by others

References

K. Roa, E. Oyarce, A. Boulett, M. ALSamman, D. Oyarzún, G.D.C. Pizarro, J. Sánchez, Sustain. Mater. Technol. 29, e00320 (2021)

P. Sirajudheen, N.C. Poovathumkuzhi, S. Vigneshwaran, B.M. Chelaveettil, S. Meenakshi, Carbohydr. Polym. 273, 118604 (2021)

A. Rafiq, M. Ikram, S. Ali, F. Niaz, M. Khan, Q. Khan, M. Maqbool, J. Ind. Eng. Chem. 97, 111 (2021)

J. Ren, X. Wang, L. Zhao, M. Li, W. Yang, J. Polym. Environ. 29, 3497 (2021)

M. Zubair, H.A. Aziz, M.A. Ahmad, I. Ihsanullah, M.A. Al-Harthi, J. Water Process Eng. 42, 102060 (2021)

H. Ye, D. Chen, N. Li, Q. Xu, H. Li, J. He, J. Lu, J. Membr. Sci. 637, 119619 (2021)

L. Das, N. Saha, A. Ganguli, P. Das, A. Bhowal, C. Bhattacharjee, Environ. Technol. Innov. 24, 101955 (2021)

A. Khatri, P.S. Rana, Physica B 579, 411905 (2020)

L. Zheng, X. Wang, X. Wang, J. Clean. Prod. 108, 525 (2015)

M.F. Sanakousar, C.C. Vidyasagar, V.M. Jiménez-Pérez, B.K. Jayanna, Mounesh, A.H. Shridhar, K. Prakash, J. Hazard. Mater. Adv. 2, 100004 (2021)

E.F.D. Januário, T.B. Vidovix, R. Bergamasco, A.M.S. Vieira, Chem. Eng. Process. 168, 108677 (2021)

E.A. Abdelrahman, J. Mol. Liq. 253, 72 (2018)

E.A. Abdelrahman, R.M. Hegazey, R.E. El-Azabawy, J. Mater. Res. Technol. 8, 5301 (2019)

R.M. Hegazey, E.A. Abdelrahman, Y.H. Kotp, A.M. Hameed, A. Subaihi, J. Mater. Res. Technol. 9, 1652 (2020)

A. Alharbi, E.A. Abdelrahman, Spectrochim. Acta A 226, 117612 (2020)

E.A. Abdelrahman, R.M. Hegazey, Y.H. Kotp, A. Alharbi, Spectrochim. Acta A 222, 117195 (2019)

A.C. Sadiq, A. Olasupo, W.S.W. Ngah, N.Y. Rahim, F.B.M. Suah, Int. J. Biol. Macromol. 191, 1151 (2021)

M.A. Khapre, S. Pandey, R.M. Jugade, Int. J. Biol. Macromol. 190, 862 (2021)

Y. Liu, Y.F. Zhang, J. Tang, Y. Tan, H. Lei, Y. Li, P. Huang, Y. Li, Colloids Surf. A 632, 127825 (2022)

V. Srivastava, A.K. Choubey, J. Mol. Struct. 1242, 130749 (2021)

E.A. Abdelrahman, R.M. Hegazey, Microchem. J. 145, 18 (2019)

E.A. Abdelrahman, R.M. Hegazey, Compos. B 166, 382 (2019)

E.A. Abdelrahman, A. Subaihi, J. Inorg. Organomet. Polym. Mater. 30, 2440 (2020)

A.A. Almehizia, M.A. Al-Omar, A.M. Naglah, M.A. Bhat, N.S. Al-Shakliah, Alexandria Eng. J. 61, 2386 (2022)

M.E. Khalifa, E.A. Abdelrahman, M.M. Hassanien, W.A. Ibrahim, J. Inorg. Organomet. Polym. Mater. 30, 2182 (2020)

X. Li, X.J. Nie, Y.N. Zhu, W.C. Ye, Y.L. Jiang, S.L. Su, B.T. Yan, Colloids Surf. A 578, 123582 (2019)

I. Khurana, A.K. Shaw, Bharti, J.M. Khurana, P.K. Rai, J. Environ. Chem. Eng. 6, 468–477 (2018)

N.D. Mu’azu, N. Jarrah, T.S. Kazeem, M. Zubair, M. Al-Harthi, Appl. Clay Sci. 161, 23 (2018)

Funding

Authors are grateful to King Saud University, Riyadh, Saudi Arabia for funding the work through Researchers Supporting Project (No. RSP-2021/359).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there is no conflict of interest for this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shah, R.K., Naglah, A.M. Nanoarchitectonics of Chitosan/Glutaraldehyde/Zinc Oxide as a Novel Composite for the Efficient Removal of Eriochrome Black T Dye from Aqueous Media. J Inorg Organomet Polym 32, 2030–2039 (2022). https://doi.org/10.1007/s10904-022-02258-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-022-02258-4