Abstract

Two kinds of new biocidal siloxane copolymers were synthesized, poly-[3(t-butylamino)propyl]methylsiloxane-co-(3-chloropropyl)methylsiloxane] and poly[dimethylsiloxane-co-(3-mercaptopropyl)methylsiloxane]-g-poly-2(t-butylamino)ethyl methacrylate]. Water-soluble derivatives of these copolymers, having charged ammonium groups, were also obtained. The copolymers were tested against two Gram-positive and three Gram-negative bacterial strains. The antibacterial tests for the water-soluble copolymers with charged ammonium groups were performed in aqueous solutions. Both these copolymers were active against the Gram-positive bacterial strains and inactive or moderately active against Gram-negative bacteria. The uncharged, insoluble, t-butylamine substituted copolymers were tested using a two-phase water-copolymer system. In this test both copolymers having the uncharged t-butylamine functions showed a high biocidal potency against the bacteria studied including those Gram-negative ones.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

Polymer biocides with antimicrobial groups chemically bonded to the polymer chain have attracted a great deal of attention as they very effectively kill bacteria and other microbes without releasing toxic low molar mass compounds to the environment. The strong biocidal potency of these polymers is a result of the high local concentration of active groups [1–7]. Salts of organic cations such as quaternary ammonium [8–15], quaternary phosphonium [15–17], N-alkylpyridinium [18–20], N-alkylimidazolium [21, 22], guanidynium [23] and organosulphonium [24] are the most commonly employed biocidal functionalites to be attached to polymers. All of these biocidal functions covalently bonded to polymers are positively charged and have a long carbon chain bonded to the nitrogen, phosphorus or sulfur atoms. Their antimicrobial activity is explained by a strong interaction with the negatively charged microbe cell wall and/or cytoplasmic membrane [1–3]. However, the ionic character of these biocidal polymers may be a serious drawback when they are used as biocidal additives to hydrophobic materials, such as silicone elastomers. The compatibility of these hydrophobic materials with charged polymers is poor. Ionic polymers show a tendency to migrate inside hydrophobic materials during the preparation of prevulcanized blends. Moreover, they may compromise some of the useful properties of materials by increasing their surface energy and dielectric constant.

Some time ago poly-2-t-butylaminoethyl methacrylate was found to be a very active antimicrobial polymer [25–27]. This polymer itself has no ionic group nor has it a long carbon chain at nitrogen. A polysiloxane analogue bearing uncharged biocidal functions would be attractive as an additive to silicone elastomers as its compatibility with these materials would be higher and its adverse effect on their useful properties would be lower than with a polysiloxane bearing charged groups.

The purpose of the research reported here is the synthesis of two types of siloxane copolymers bearing t-butylamine groups. The first (Scheme 2) is the (3-t-butylaminopropyl)methylsiloxane polymer, which also contains a number of (3-chloropropyl)methylsiloxane units as precursors for the amine-substituted units. The second copolymer (Scheme 3) is polydimethylsiloxane with grafted short oligo-2(t-butylamino)ethyl methacrylate chains. This copolymer may contain a number of unreacted (3-mercaptopropyl)methylsiloxane units, which could be used in further studies to cross-link the copolymer by a tiol-ene addition process. The second copolymer with its methacrylate chains with t-butylamine functions was chosen because this chain has been shown to have a great biocidal potency [25–27]. The first copolymer has a quite different structure from the second because it contains t-butylamine side groups attached to a polysiloxane chain by trimethylene bridges. Studies of the antibacterial activity of these copolymers and their protonated derivatives may throw some light on the mechanism of the biocidal action of t-butylamine substituted polymers. It is not quite clear whether the high biocidal potency of poly-2(t-butylamine)ethyl methacrylate is an inherent property of tertiary butylamine function [25] or a feature of a special structure of the whole polymer [26].

2 Experimental

2.1 Analytical Methods

1H NMR spectra were performed using a Brucker AC-200 spectrometer. Deuterated methanol was used as solvent. 29Si NMR spectra were recorded with a Bruker AC-500 instrument working at 99.36 MHz in the inverse gated pulse sequence mode with relaxation delay of 5 s, scan number 1,000, time domain 65.5 K and 90° pulse 15.00 μs. CDCl3 was used as solvent. 13C NMR were recorded with a Bruker AC-200 spectrometer working at 50.34 MHz using the inverse gated pulse sequence mode with relaxation delay of 20 s, scan number 2,000, time domain 32.8 K and 90° pulse 7.00 μs. CDCl3 was used as solvent.

Gas Chromatography analyses were performed using a Hewlett Packard HP 6890 chromatograph equipped with a thermal conductivity detector and standard Hewlett Packard HP1 capillary column l = 30 m, d = 0.53 mm packed with cross-linked polydimethylsiloxane (0.88 μm film thickness). Helium carrier gas was used: flow rate, 5 mL/min; detector temperature 250 °C; injector temperature 250 °C; column temperature program, 3 min at 50 °C (isothermal), 40–240 °C at 10 °C/min, 10–15 min (isothermal).

The size exclusion chromatography analysis was performed using an LDC analytical RefractoMonitor instrument with two phenogel columns covering the molar mass range of 102–105 g/mol and a refractive index detector. Toluene was used as eluent and polystyrene as the standard.

2.2 Chemicals

2-(t-Butylamino)ethyl methacrylate, Aldrich 97% was stored over CaH2 and distilled before use; Fluoresceine O-methacrylate, Aldrich 97%; (3-chloropropyl)methyldichlorosilane, ABCR 95%; (3-mercaptopropyl)trimethoxysilane, ABCR 95%; (3-mercaptopropyl)methyldimethoxysilane ABCR 95%; octamethylcyclotetrasiloxane ABCR 97%; t-Butylamine, Aldrich 98%; ethyl bromide, Fluka 99%; AIBN Aldrich 98%. These chemicals were reagent grade and were used without purification. Purity was checked by gas chromatography. n-Hexane, Lab-Scan 95%, analytical grade was dried with MgSO4 and distilled from sodium. DMF POCh pure was dried with MgSO4 for 1 day and distilled under reduced pressure. Methanol Chempur pure p.a. and n-butanol POCh pure p.a. were used without purification.

2.3 Synthesis of Polysiloxanes Substituted with 3-t-Butylaminopropyl Groups 3a and 3b

Precursor polymer, (3-chloropropyl)methylsiloxane 1a, M n = 6.0 × 103 g/mol, M w/M n = 2.1, was synthesized according to a method described elsewhere [28]. Cyclic oligomers were carefully removed from this copolymer by its precipitation from methylene chloride solution with a limited amount of methanol. Polymer 1a (1.04 g, 7.62 × 10−3 mol of Cl) was mixed with t-butylamine (5.55 g, 0.076 mol) and dissolved in a mixture of n-butanol (6 mL) and dimethylformamide (3 mL). The solution was kept at 80 °C for 250 h. Then solvents and an excess of amine were removed under reduced pressure and the obtained copolymer 2a (1.3 g, 90% yield) was analyzed by 1H NMR spectroscopy. The yield for the conversion of the chloropropyl group into t-butylaminopropyl hydrochloride was 76%. 1H NMR (solvent CD3OD, in ppm): 0.1–0.3 (b.s. CH 3Si); 0.6–0.8 (b.s. CH 2Si); 1.3–1.55 [b.s. (CH 3)3C]; 1.75–2.0 (b.s. CH2CH 2CH2); 2.9–3.05 (b.t. CH 2N); 3.1–3.25 (b.s. CH 2Cl). Copolymer 2a (1.00 g, 7.2 × 10−3 mol Cl) was dissolved in a mixture of methanol (20 mL) and triethylamine (10 mL). The solution was stirred at ambient temperature for 24 h. The precipitate of Et3N–HCl was separated and an excess of Et3N and methanol was distilled off under reduced pressure. Then the copolymer was dissolved in a fresh portion of methanol (20 mL). Then pyridine (20 mL) was introduced and the solution was stirred for 3 days at ambient temperature after which it was filtered from precipitated pyridine hydrochloride. Methanol and pyridine were distilled off under reduced pressure. The remaining product, copolymer 3a (0.85 g, 98% yield) was dissolved in 20 mL of methanol and precipitated in a large volume of water. An AgNO3 test showed that it did not contain chloride. It was subjected to 1H NMR analysis (solvent CDCl3, in ppm): 0.0–0.25 (b.s. CH 3Si); 0.45–0.75 (b.s. CH 2Si); 1.3–1.6 [b.s. (CH 3)3C]; 1.85–2.15 (b.s. CH2CH 2CH2); 2.7–2.95 (b.s. CH 2N); 3.2–3.35 (b.s. CH 2Cl). Copolymer 3a, in contrast to copolymer 2a, was not soluble in water. In analogous way copolymers 2b and 3b were synthesized from poly(3-chloropropyl)methylsiloxane 1b, M n = 4.2 × 104 g/mol, M n /M w = 2.3. 2b contained 78% of the amine hydrochloride substituted units, which were converted to free amine substituted units in 3b.

2.4 Determination of the Chain Transfer Constant to (3-mercaptopropyl)trimethoxysilane in the Radical Polymerization of 2-t-Butylaminoethyl Methacrylate

In a 100 mL Schlenk flask purged with argon and immersed in a bath at temperature 60 °C, 3-mercaptopropyltrimethoxysilane (2.00 g, 1.02 × 10−2 mol), 2-(t-butylamino)ethyl methacrylate (1.88 g, 1.014 × 10−2 mol), n-hexane (3.88 g), n-nonane (0.26 g) (GC standard) and 2,2′-azobis(2-methylpropionitrile) (AIBN) (0.0.072 g, 4.4 × 10−4 mol), were placed. The mixture was stirred with a magnetic stirrer at 60 °C in an atmosphere of slowly flowing argon. Conversions of the monomer and the transfer agent were monitored by sampling and gas chromatography technique. The chain transfer constant k tr/k p = 0.6, (k tr and k p are rate constants of chain transfer and propagation, respectively) was found from the ratio of the chain transfer agent to monomer consumption in the early stage of the polymerization.

2.5 Synthesis of Oligo-[2(t-butylamino)ethyl methacrylate] Grafted on Polysiloxane 6a and 6b

(3-Mercaptopropyl)methyldimethoxysilane (20.4 g, 0.113 mol) was slowly introduced to distilled water (6.5 g, 0.36 mol) and HCl 36% aqueous solution (0.5 mL) placed in a glass reactor, equipped with a stirrer, dropping funnel and an ice-water bath. Stirring the mixture was continued while it was allowed to attain room temperature. Volatile components were distilled off under reduced pressure. The remaining hydrolysate 4 was composed of linear and cyclic oligo(3-mercaptopropyl)methylsiloxanes. This hydrolysate (5.33 g, 0.040 mol of SH) was mixed with octamethylcyclotetrasiloxane (D4) (23.7 g, 0.32 mol of Me2SiO units), hexamethyldisiloxane (1.15 g, 7.1 × 10−3 mol) and trifluoromethanesulfonic acid (1.70 × 10−3 mol). The mixture was stirred at room temperature for 50 h. This precursor copolymer 5 was dissolved in methylene chloride (20 mL) and the solution was washed several times with water until neutral pH was attained. The copolymer was precipitated from its methylene chloride solution with a limited amount of methanol to get rid of cyclic oligomers and dried under a reduced pressure. Copolymer 5 (20.1 g, 67% yield) was obtained and subjected to 1H NMR, 29Si NMR investigation and SEC analysis. 1H NMR (solvent CDCl3, in ppm): −0.05–1.5 (b.s. CH 3Si); 0.56–0.68 (m. CH 2Si); 1.25–1.35 (t. SH); 1.55–1.69 (m. CH2CH 2CH2); 2.47–2.57 (q. CH 2SH). 29Si NMR (solvent CDCl3, in ppm): −23.1–(−23.6) [b.m. MeSi(CH2)3SH]; −21.6–(−22.0) [b.m. SiMe2]; 5.23–5.26 (s. SiMe3); M n (from 29Si NMR) 1.44 × 104 g/mol SEC (polystyrene standard): M n 1.3 × 104 g/mol; M w/M n 1.85. Average macromolecule contained (by NMR): 18 [3-HS(CH2)3MeSiO] units, 160 [Me2SiO] units and 2 Me3SiO0.5 units.

Copolymer 5 (1.50 g, 1.88 × 10−3 mol of the SH containing units) was mixed with 2(t-butylamino)ethyl methacrylate (2.76 g, 14.9 × 10−3 mol), dried n-hexane (4.3 mL) and AIBN (0.092 g, 5.6 × 10−4 mol). The mixture was stirred at 60 °C for 1.5 h in an atmosphere of nitrogen. The polymerization was controlled by gas chromatography and performed to about 80% of monomer conversion. Solvent and remaining monomer were removed by evaporation at reduced pressure (2 mm). Graft copolymer 6a (2.50 g, 85% yield) was purified from the 2(t-butylamino)ethyl methacrylate homopolymer by precipitation from its methanol solution with a limited amount of the mixture of methanol with water 1:1 (v/v). The operation was repeated five-times until the ratio of the integration of the CH 3C/CH 3Si signals in the 1H NMR spectrum did not change. The copolymer was dried under reduced pressure and analyzed. 1H NMR (solvent CD3OD, in ppm): 0.04–0.2 (b.s. CH 3Si); 0.6–0.72 (b.s. CH 2Si); 0.9–1.05, 1.05–1.2, 1.2–1.35 (b.m. CH 3CCO); 1.1–1.25 (b.s. CH 3CN); 1.6–1.75 (b.s. CH2CH 2CH2); 1.75–2.2 (b.m. CH 2C); 2.5–2.65 (b.m. CH 2S); 2.65–2.75 (CH); 2.75–2.9 (b.m. CH 2N); 4.0–4.25 (b.m. CH 2O). 13C NMR (solvent CDCl3): −0.537 (CH3)3Si; 0.986 (CH3)2Si; 1.730 CH3SiCH2; 16.963 CH2Si; 28.960 (CH3)3C; 30.882 CH2S; 40.819 CH2N; 44.694, 45.006 CH2C; 50.167 CN; 65.513 CH2O. Copolymer 6a had M n = 2.4 × 104 g/mol. The average macromolecule contained 160 Me2SiO units and about seven units with a grafted oligo[2-t-butylaminoethyl] methacrylate chain, which contained about nine methacrylate units on average (together 2.6 × 10−3 mol/g t-butylamine).

The polymerization was repeated using 2.00 g (3.97 × 10−3 mol of the SH containing units) of copolymer 5, 3.68 g (19.9 × 10−3 mol) of 2(t-butylamino)ethyl methacrylate, 0.123 g (7.5 × 10−4 mol) of AIBN in 7 mL of n-hexane. The mixture was stirred for 12 h at 60 °C. The polymerization proceeded almost to full monomer conversion. After the removal of solvent, 3.5 g (78% yield) of raw grafted copolymer 6b was isolated and subjected to purification from the methacrylate homopolymer. 6b had M n = 3.4 × 104 g/mol and contained on average 110 t-butylamine substituted units; about six units per graft.

2.6 Synthesis of Oligo-[2(N,N-t-butylethylammonio)ethyl methacrylate bromide] Grafted on Polysiloxane 7b

Copolymer 6b (0.30 g, 9.6 × 10−4 mol t-butylamine) was subjected to the Mienschutkin reaction with ethyl bromide (5.84 g, 5.4 × 10−2 mol) in DMF (10 mL). The reaction was carried out at room temperature for 7 days. The solvent and excess of ethyl bromide were evaporated at a reduced pressure. Soluble in water copolymer 7b was obtained (0.54 g) having about 90% of its amine groups converted to ammonium groups as determined from 1H NMR. 1H NMR (solvent CD3OD, in ppm): 0.05–0.15 (b.s. CH 3Si); 0.6–0.7 (b.s. CH 2Si); 0.95–1.25 (b.m. CH 3C); 1.3–1.4 (b.t. CH 3CH2Si); 1.45–1.6 [b.s. (CH 3)3C, CH2CH 2CH2]; 2.0–2.3 (b.s. CH 2C); 2.5–2.6 (b.s. CH 2S); 3.35–3.5 (b.m. CH 2N); 4.35–4.55(b.s. CH 2O).

2.7 Antibacterial Activity Assessment

The antibacterial tests for the cationic biocidal copolymers were performed in aqueous solutions using a method similar to that described elsewhere [21]. The minimum inhibitory concentrations (MIC) and the minimum bactericidal concentrations (MBC) were determined for five bacteria strains: Staphylococcus aureus (ATCC 6538), Enterococcus hirae (ATTC 10541), Escherichia coli (ATTC 8739), Proteus vulgaris (NCTC 4635) and Pseudomonas aeruginosa (ATCC 9027). The MIC and MBC determinations were performed in three independent measurements using the standard broth dilution technique [28] with inoculums of approximately 1 × 105 CFU mL−1. The tested copolymers were dissolved, diluted in geometric progression and dispensed into the wells of a microplate to which an overnight bacterial culture, diluted with Mueller–Hinton broth to the proper density, was introduced. Microplates were incubated for 24–36 h at 37 °C. Then the growth of bacteria in the wells was examined to determine the MIC value, which was taken as a lowest concentration of copolymer that inhibits visible growth of bacteria. The MBC value was found by the observation of the ability of the bacteria with inhibited growth to survive after transfer to Mueller–Hinton agar plate. The MBC value was taken as a lowest concentration of copolymer that would kill all visible bacteria.

Another method was used in the antibacterial tests for non-ionic biocidal copolymers, which were insoluble in water. Round flat bottom wells of the diameter of Φ = 1.2 cm of polystyrene cell culture multi-dishes were coated with a biocidal copolymer layer of 1 mm thickness. For this purpose concentrated solutions of these polymers in methanol were placed in wells and the solvent was evaporated. Some wells were additionally washed eight-times with water and dried. Then the coated multi-dishes were heated in a drying box at 60 °C for 5 h. A bacterial culture, 400 μL, with suitable optical density was dispensed to a well. Samples of 20 μL of the bacterial suspension were withdrawn in a time interval starting from time zero. They were diluted 10-, 100-, and 1,000-fold. A 100 μL of each dilution was transferred to an agar plate and incubated at 37 °C for 24 h. Colony forming units, CFU, were calculated using Scheme 1.

3 Results and Discussion

3.1 Synthesis of 3-t-Butylaminopropyl Substituted Polysiloxanes

Poly(3-t-butylaminopropyl)methylsiloxane-co-(3-chloropropyl)methyl-siloxane was obtained by the partial amination of 3-chloropropyl groups in a (3-chloropropyl)-methylsiloxane polymer by t-butylamine according to Scheme 2.

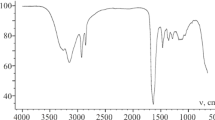

Precursor polymers 1a and 1b, poly(3-chloropropyl)methylsiloxanes, were synthesized by cationic equilibrium polymerization (equilibration) of the cyclic siloxane polymer products by hydrolytic polycondensation of [3-Cl(CH2)3]MeSiCl2 in a similar way to that described previously [29]. Hexamethyldisiloxane (MM) was added to limit the molar mass of the copolymer and to terminate the chain by Me3Si groups. Volatile cyclic oligomers were removed by the precipitation of the copolymer from methylene chloride solution with a limited amount of methanol. The amination (Menschutkin reaction) was performed by heating a mixture of the precursor copolymer with a large excess of t-butylamine in a dimethylformamide (DMF)-n-butanol solution. The course of the reaction was monitored by proton NMR. The reaction was stopped when at least 70% of the chloropropyl groups had reacted. In this way copolymers 2a and 2b were obtained whose amine groups were complexed with HCl. They were treated with a large excess of triethylamine and subsequently with pyridine to obtain the free amine substituted copolymers, 3a and 3b. These were additionally purified by precipitation in water from methanol solution. The 1H NMR spectrum of copolymer 3a is presented in Fig. 1. The characteristics of copolymers are shown in Tables 1 and 2.

3.2 Synthesis of t-Butylamine Substituted Oligomethacrylate Grafted on Polysiloxane

Chain transfer polymerization was used for the grafting of polymethacrylate bearing t-butylamine in the ester groups on a polysiloxane chain. The synthesis of poly[dimethylsiloxane-co-(3-mercaptopropyl)methylsiloxane]-g-poly(2-t-butylaminoethyl methacrylate) was performed according to Scheme 3.

The precursor siloxane copolymer 5, functionalized with 3-mercaptopropyl groups, was synthesized by cationic equilibrium copolymerization of octamethylcyclotetrasiloxane with the hydrolyzate of (3-mercaptopropyl)methyldiethoxysilane and catalyzed by CF3SO3H. Hexamethyldisiloxane was added to control the molar mass of the copolymer product. The copolymer, after the removal of cyclic compounds, was characterized by 1H and 29Si NMR and SEC.

2-(t-butylamino)ethyl methacrylate was subjected to radical polymerization initiated with 2,2′-azobis(2-methylpropionitrile (AIBN) in the presence of the precursor siloxane copolymer 5. 3-Mercaptopropylsilyl groups pendant to the polysiloxane chain were efficient chain transfer agents in this radical polymerization [30]. The chain transfer to this group led to the grafting of the oligomethacrylate chain to polysiloxane through a thioether bridge. We assumed that the chain transfer constant in this system would be similar to that for the chain transfer to 3(mercaptopropyl)trimethoxysilane, which was determined in separate experiment (see Sect. 2). The value of this constant was k tr/k p = 0.6 where k tr and k p are chain transfer constant and propagation constant, respectively. This means that the molar ratio of monomer-to-chain transfer agent changes fairly little when the polymerization proceeds. Thus, the reaction may be performed to give high monomer conversion. The methacrylate homopolymer was removed by careful precipitation of the graft copolymer product from its methanol solution by the addition of a limited amount of a water–methanol mixture. This precipitation procedure was repeated until the ratio of intensities of NCCH 3 and SiCH 3 peaks in the copolymer 1H NMR spectrum did not change after subsequent precipitation. The obtained graft copolymers 6a and 6b, which were synthesized from the same precursor polysiloxane, differed in the number of t-butylamine functions and in the number of grafts. Copolymers 6a and 6b were characterized by SEC and 1 H NMR (Fig. 2.

This water-insoluble free-amine-substituted copolymer 6b was subjected to alkylation with ethyl bromide to prepare a polysiloxane 7b that is grafted with oligomethacrylate having [2(N,N-t-butylethylammonio)ethyl bromide] ester groups, which made this copolymer water-soluble.

3.3 Microbiological Studies

Biocidal activity determination of polymers is usually practiced on a material surface. However, the antibacterial properties of various chemical structures can be compared in a satisfactory way in aqueous solutions while the biocidal action of surfaces depends on many other factors. This was the reason why t-butylamine substituted siloxane copolymers as their water-soluble ammonium salts were studied here. The antibacterial properties of these materials were studied in aqueous solutions using the broth dilution method, which allows the determination of the MIC and the MBC (minimum biocidal concentration) of our copolymers. This approach permitted us to compare the biocidal potency of both types of t-butylammonio-substituted siloxane copolymers with a quaternary ammonium salt-containing polysiloxanes synthesized here. Studies were performed for two Gram-positive bacterial strains, Enterococcus hirae and Staphylococcus aureus as well as for three Gram-negative bacterial strains, Escherichia coli, Proteus vulgaris and Pseudomonas aeruginosa. For each of the biocide-bacterial strain pairs the MIC and MBC was evaluated three times with good agreement between these measurements. The results of studies in aqueous solutions are shown in Table 1.

A high antibacterial activity against Gram-positive bacteria was observed for both t-butylammonium substituted siloxane copolymers 2a, 2b and 7b, although their activity is somewhat lower than that of the polysiloxane substituted by a quaternary ammonium salt with the longer hydrocarbon chain C8 at nitrogen (polymer 8). Copolymers studied here were also active against Escherichia coli but their activity against the other Gram-negative bacteria studied here was very low. This observation seems to be consistent with a mechanism of biocidal action of poly[2(t-butylamino)ethyl methacrylate] discussed by Jerome et al. [25]. This mechanism assumes the operation of the charged protonated form of the t-butylamino group, thus having a similar structure to the active ammonium groups in our copolymers. The authors assume that these protonated groups are present at the water–polymer interface and exchange their protons to Ca++ and Mg++ ions, which are drawn from the cell membrane of Escherichia coli. This is the cause of the membrane disruption, which leads to the cell death. Gram-positive bacteria have only one membrane, so they are very sensitive to the biocidal action of the t-butylamino group in agreement with Jerome’s mechanism. On the other hand double membranes cells of Proteus vulgaris and Pseudomonas aeruginosa make the lysis of the cells difficult, although in the case of Escherichia coli the presence of the second membrane does not give the bacteria cell sufficient protection.

In contrast to the data from aqueous solutions, the results of the examination of antibacterial activity of water insoluble polymers (Table 2) can be only compared on a qualitative basis. We believe that the interaction of the polymer with a bacterial cell occurs mostly at the polymer–water interface, although we cannot reject the possibility that a negatively charged bacterial cell in contact with the polymer surface extracts some macromolecules to the aqueous phase. Some of the copolymers studied here were washed eight-times with water after coating the bottom of the multi-dish wells. This operation did not cause a substantial difference in the biocidal activity of these materials as demonstrated in Fig. 3.

The reduction of Staphylococcus aureus in its aqueous suspension being in contact with poly-2-t-butylaminoethyl methacrylate grafted on polydimethylsiloxane, copolymer 6b: solid lines the copolymer used after 8-fold washing with water, dashed lines the copolymer used without the prewashing operation

However, the results in Table 2 unambiguously point to a high antibacterial activity of our copolymers. Both of them, i.e., one having t-butylamine groups pendant to polysiloxane chain and one with the oligo-2-(t-butylamino)ethyl methacrylate grafted on polysiloxane, are very active against the bacterial strains studied. In particular, they also exhibit a high potency against the Gram-negative strains, which are resistant to their water soluble protonated derivatives. Our preliminary study by SEM showed no bacteria on the biocidal polymer surface after the two-phase system experiment; therefore, the reduction of CFU does not seem to be due to the adsorption of bacteria by biocidal surface. The above observations in combination with the results obtained in aqueous solutions may mean that the mechanism of the biocidal action of t-butylamino-substituted polymers is more complex than it has so far been assumed. In any case, the structure of our copolymers, in particular those of 3a and 3b, are different from the polymers and copolymers of 2(t-butylamino)ethyl methacrylate that were studied in Ref. [25–27]. Therefore, their high antibacterial activity indicates that a high biocidal potency of the t-butylamine-substituted methacrylate chain is not only due to a specific structure of the helical polymethacrylate chain, but is rather a general feature of the t-butylamino substituent in a polymer chain.

4 Conclusions

New siloxane copolymers bearing t-butylamine function were synthesized and shown to be active bacteriocides. Polysiloxanes with 3-t-butylaminopropyl groups pendant to polymer chain may be synthesized by the reaction of 3-chloropropylmethylpolysiloxane with t-butylamine followed by dehydrochlorination with triethylamine and pyridine. Grafting of poly-2(t-butylamino)ethyl methacrylate on the polysiloxane chain may be performed by free radical polymerization of 2(t-butylamino)ethyl methacrylate in the presence of a polysiloxane substituted with 3-mercaptopropyl group that is pendant to the polysiloxane chain. The chain transfer constant to the 3-mercaptopropyl group in this process is 0.6 (60 °C), thus is fairly close to 1, which means that the molar ratio of monomer-to-chain transfer groups is little changed as the reaction proceeds. Poly{[3(t-butylamino)propyl]methylsiloxane-co-(3-chloropropyl)methylsiloxane} and poly[dimethylsiloxane-co-(3-mercaptopropyl)methylsiloxane]-g-poly(2-t-butylaminoethyl methacrylate) show a high antibacterial potency against Gram-positive and Gram-negative bacterial strains when these copolymers are in contact with an aqueous suspension of bacteria. Aqueous solutions of water-soluble derivatives of these polymers, poly{[3(t-butylamonio)propyl]methylsiloxane chloride-co-3-chloropropylmethylsiloxane} and poly[dimethylsiloxane-co-(3-mercaptopropyl)methylsiloxane]-g-poly [2(N,N-t-butylethylammonio)ethyl methacrylate bromide], show a high biocidal activity against Gram-positive bacterial strains (Staphylococcus aureus and Enterococcus hirae). In most cases their MIC and MBC values are in the range of 20–80 μg/mL. Their activity against Gram-negative bacteria (Proteus vulgaris and Pseudomonas aeruginosa) is very low; however, they exhibit moderate activity against Escherichia coli (MIC and MBC are 80–300 μg/mL).

The biocidal properties of t-butyl-substituted polymers are rather general and are related to the presence of t-butyl group. The mechanism of the biocidal action of t-butylamine substituted polymers is more complex as suggested earlier [25–27]. Antibacterial properties are not only the result of a specific helical conformation of the polymethacrylate chain that bears the amine groups nor are they solely due to a protonated structure of this amine. The biocidal polymers obtained here are uncharged and contain a polysiloxane chain so they should be more compatible with silicone materials as compared with charge-loaded polymers such as cationic polymer biocides.

References

E.R. Kenawy, S.D. Worley, R. Broughton, Biomacromolecules 8, 1359 (2007)

S.D. Worley, G. Sun, Trends Polym. Sci. 4, 364 (1996)

A.M. Klibanov, J. Mater. Chem. 17, 2479 (2007)

T. Tashiro, Macromol. Mater. Eng. 286, 63 (2001)

J. Hazziza-Laskar, G. Helary, G. Sauvet, J. Appl. Polym. Sci. 58, 63 (1995)

C.Z. Chen, N.C. Beck-Tan, P. Dhurjati, T.K. Van Dyck, R.A. LaRossa, S.L. Cooper, Biomacromolecules 1, 473 (2000)

A.D. Fuchs, J.C. Tiller, Angew. Chem. Int. Ed. 45, 6759 (2006)

N. Nurdin, G. Helary, G. Sauvet, J. Appl. Polym. Sci. 50, 671 (1993)

B. Dizman, M.O. Elasri, L.J. Mathias, J. Polym. Sci. A 44, 5965 (2006)

G.Q. Lu, D.C. Wu, R.W. Fu, React. Funct. Polym. 67, 355 (2007)

C. Hugues, C. Bessy, P. Bartolomeo, A. Margaillan, Eur. Polym. J. 39, 319 (2003)

S. Punyani, H. Singh, J. Appl. Polym. Sci. 102, 1038 (2006)

C.Z.S. Chen, S.L. Cooper, Biomaterials 23, 3359 (2002)

S. Lenoir, C. Pagnoulle, C. Detrembleur, M. Galleni, R. Jerome, J. Polym. Sci. A 44, 1214 (2006)

E.R. Kenawy, F.I. Abdel-Hay, A.E.R.R. El-Shanshoury, M.H. El-Newehy, J. Polym. Sci. A 40, 2384 (2002)

A. Kanazawa, T. Ikeda, Coord. Chem. Rev. 198, 117 (2000)

A. Kanazawa, T. Ikeda, T. Endo, J. Polym. Sci. A 31, 1467 (1993)

G. Cerichelli, C. La Mesa, L. Luchetti, G. Mancini, Langmuir 16, 166 (2000)

G.J. Li, J.R. Shen, Y.L. Zhu, J. Appl. Polym. Sci. 78, 668 (2000)

J.C. Tiller, S.B. Lee, K. Lewis, A.M. Klibanov, Biotechnol. Bioeng. 79, 465 (2002)

U. Mizerska, W. Fortuniak, J. Chojnowski, R. Hałasa, A. Konopacka, W. Werel, Eur. Polym. J. 45, 779 (2009)

H. Caner, E. Yilmaz, O. Yilmaz, Carbohydr. Polym. 69, 318 (2007)

C. Soykan, R. Coskun, S. Kirbag, J. Macromol. Sci. A 44, 31 (2007)

M. Albert, P. Feiertag, G. Hayn, R. Saf, H. Hönig, Biomacromolecules 4, 1811 (2003)

S. Lenoir, C. Pagnoulle, M. Galleni, C. Compere, R. Jerome, C. Detrembleur, Biomacromolecules 7, 2291 (2006)

P. Ottersbach, B. Kossmann, German Patent DE 10,244,489 (2004)

P. Ottersbach, F. Sosna, Eur. Pat. Appl. EP 1,281,490 (2003)

J.M. Andrews, J. Antimicrob. Chemother. 48(Suppl. S1), 87 (2001)

G. Sauvet, S. Dupond, K. Kazmierski, J. Chojnowski, J. Appl. Polym. Sci. 75, 1005 (2000)

J.C. Saam, D.J. Gordon, J. Polym. Sci. A 8, 2509 (1970)

Acknowledgments

The research was supported from the state funds, Project no. N205 129935 and Project no. N205 012834. The supports from The Medical University of Gdansk and from The Center of Molecular and Macromolecular Studies of the Polish Academy of Sciences also are greatly appreciated. The improvement of English of this paper by Prof. Alan Bassindale is also warmly appreciated.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper is dedicated to Professor Charles U. Pittman Jr. in recognition of his significant contributions to the field of materials chemistry.

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Mizerska, U., Fortuniak, W., Chojnowski, J. et al. Antimicrobial Siloxane Statistical and Graft Copolymers Substituted with t-Butylamine and t-Butylammonium Biocidal Functions. J Inorg Organomet Polym 20, 554–563 (2010). https://doi.org/10.1007/s10904-010-9379-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-010-9379-0