Abstract

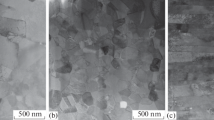

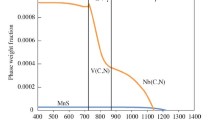

An alloy composition of reduced-activation Cr–W–V ferritic steels for nuclear fusion reactors was studied. The formation of nano-metric precipitates through standardized heat treatments in Cr–W–V alloy system is investigated using microscopic observations. Metallography studies have revealed that the micro-structure of alloy after tempering has been Martensite. Also after tempering, the matrix structure of alloy and the formation of nano-scale precipitates on grain and lath boundaries were confirmed by the Scanning Electron Microscope observations. By the application of X-ray Diffraction spectra analysis and transmission electron microscopy (TEM) electron diffraction patterns, it was shown that the type of precipitates extracted from alloy, would be M23C6 and M7C3 that include a cubic and trigonal crystal structure, respectively. TEM analysis has revealed that the morphology of these structural components is mainly spherical and blocky shapes and the average length and thickness of them would be 65 and 50 nm, respectively.

Similar content being viewed by others

References

B. van der Schaaf, D.S. Gelles, S. Jitsukawa, A. Kimura, R.L. Klueh, A. Moslang, G.R. Odette, J. Nucl. Mater. 283, 52–59 (2000)

K. Asakura, Y. Yamashita, T. Yamada, K. Shibata, Effects of Ta and Nb on microstructures and mechanical properties of low activation ferritic 9Cr–2W–0.2 V steel for fusion reactor. ISIJ Int. 30(1), 937–946 (1990)

P. Chakraborty et al., J. Fusion Energ. (In press, November 2014). doi:10.1007/s10894-014-9800-8

R. Jayaram, R.L. Klueh, Micro-structural characterization of 5 to 9 pct Cr-2 pct W–V–Ta martensitic steels. Metall. Trans. 29A, 1551–1558 (1998)

R.L. Klueh, Elevated-temperature ferritic and martensitic steels and their applications to future nuclear reactors. Int. Mater. Rev. 50(5), 287 (2004)

H. Sakasegawa, T. Hirose, A. Kohyama, Y. Katoh, T. Harada, K. Asakura, T. Kumaga, Effects of precipitation morphology on toughness of reduced activation ferritic/martensitic steels. J. Nucl. Mater. 307–311, 490–494 (2002)

Elarbi, Y. M., Weldability of high Cr and 1 % tungsten alloyed creep resistant martensitic steel, Budapest University of Technology and Economics Faculty of Mechanical Engineering, Department of Material Science Engineering, Thesis, 2008

P. Fernandez, M. Garc-Mazar, A.M. Lancha, J. Lapena, Grain boundary microchemistry and metallurgical characterization of Eurofer 97 after simulated service conditions. J. Nucl. Mater. 329–333, 273–277 (2004)

J. Janovec, M. Svoboda, J. Blach, Evolution of secondary phases during quenching and tempering 12 %Cr steel. Mater. Sci. Eng. 249A, 184–189 (1998)

T. Okuno, Effect of microstructure on the toughness of hot work tool steels, AISI H13, H10, and H19. ISIJ Int. 27, 51–59 (1987)

R.C. Thomson, H.K.D.H. Bhadeshia, Changes in chemical composition of carbides in 2.25Cr–1Mo power plant steel part 2: mixed microstructure. Mater. Sci. Tech. 10, 205–208 (1994)

F. Yana, H. Shib, J. Fanb, Z. Xua, An investigation of secondary carbides in the spray-formed high alloyed vanadis 4 steel during tempering. Mater. Character. 59, 883–889 (2008)

N. Fujita, Modeling carbide precipitation in alloy steels, Department of Material Science and Metallurgical, University of Cambridge, Thesis, 2000

C.A. Danon, C. Servant, Thermodynamic modeling in reduced activation steels. ISIJ Int. 45(6), 903–912 (2005)

R. Viswanathan, W. Bakker, J. Mater. Eng. Perf. 10, 81–95 (2001)

S.I. Porollo, A.M. Dvoriashin, Y.V. Konobeev, F.A. Garner, Microstructure and mechanical properties of ferritic/martensitic steel EP-823 after neutron irradiation to high doses in BOR-60. J. Nucl. Mater. 329–333, 314–318 (2004)

Yamasaki, S., Modeling precipitation of carbides in martensitic steels, University of Cambridge, Thesis, 2005

P. Fernandez, A.M. Lancha, J. Lapena, M. Hernandez-Mayoral, Metallurgical characterization of the reduced activation ferritic/martensitic steel Eurofer 97 on as-received condition. Fus. Eng. Des. 58–59, 787–792 (2001)

S. Das, A. Joarder, Effect of long-term service exposure at elevated temperature on microstructural changes of 5Cr–0.5Mo steels. Metall. Mater. Trans. A 28A, 1607–1616 (1997)

D.R.G. Mitchell, C.J. Ball, A quantitative X-ray diffraction and analytical electron microscopy study of service exposed 2.25Cr–1Mo steels. Mater. Character. 47, 17–26 (2001)

P. Fernandez, M. Hernandez-Mayoral, J. Lapena, A.M. Lancha, G. De Diego, Correlation between microstructure and mechanical properties of reduced activation modified F–82H ferritic martensitic steel. Mater. Sci. Tech. 18, 1353–1361 (2002)

V. Thomas Paul, S. Saroja, M. Vijayalakshmi, Microstructural stability of modified 9Cr–1Mo steel during long term exposures at elevated temperatures. J. Nucl. Mater. 378, 273–281 (2008)

J.D. Robson, H.K.D.H. Bhadeshia, Modeling precipitation sequences in power plant steels part 2—application of kinetic theory. Mater. Sci. Tech. 13, 640–644 (1997)

H Magnusson, Creep modelling of particle strengthened steels, Department Material Science Engineering, Royal Institute of Technology, Thesis, 2007

J.M. Race, H.K.D.H. Bhadeshia, Precipitation sequences during carburization of Cr–Mo steel. Mater. Sci. Tech. 8, 875–882 (1992)

Robson, J. D., Modeling of carbide and laves phase precipitation in 9–12 wt% chromium steels, University of Cambridge, Thesis, 1996

D. Gaude-Fugarolas, Y. De Carlan, Modelling precipitate distribution in reduced-activation steels. J. Nucl. Mater. 374, 109–115 (2008)

R. Schaublin, P. Spatig, M. Victoria, Microstructure assessment of the low activation ferritic/martensitic steel F–82H. J. Nucl. Mater. 258–263, 1178–1182 (1998)

M. Tamura, H. Kusuyama, K. Shinozuka, H. Saka, Tempering process and precipitation behavior of 8 %Cr–2 %WTa steel. ISIJ Int. 47(2), 317–326 (2007)

Z. Chen, Z.W. Shan et al., Fine carbide strengthened 3Cr–3WVTa bainitic steel. Metall. Mater. Trans. A 35A, 1281–1287 (2004)

Acknowledgments

The authors would like to thank the advanced materials group of materials research school (NSTRI) for its financial supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moniri, S., Ghoranneviss, M., Hantehzadeh, M.R. et al. Nano-Scale Precipitates of Reduced Activation Steels for the Application of Nuclear Fusion Reactors. J Fusion Energ 34, 449–455 (2015). https://doi.org/10.1007/s10894-014-9822-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10894-014-9822-2