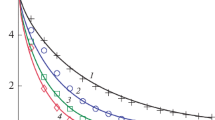

Based on the zonal method, the temperature and concentration dependences of the moisture diffusion coefficient in materials subject to shrinkage in the process of drying (plates cut from apple, carrot, and beet) were found experimentally. The concentration dependences of the moisture diffusion coefficient in these materials were determined from drying curves obtained in the absence of external diffusion resistance. Shrinkage of materials was determined experimentally, the temperature dependences of the obtained diffusion coefficients were described on the basis of the theory of activated molecular diffusion of moisture in the material. It is shown that the temperature dependence of the moisture diffusion coefficient in the indicated materials is described satisfactorily by the Arrhenius equation, on the basis of which, for these materials, formulas were obtained that express the dependence of the coefficient of moisture diffusion in them on their moisture content and temperature and that can be used in engineering calculations. The obtained data on the moisture diffusion coefficient in the studied materials are compared with similar data obtained for other materials. It is shown that the concentration dependences of the moisture diffusion coefficients of materials subject to shrinkage during drying have the same nature and order of magnitude as similar dependences for materials without shrinkage. The drying curves calculated using the obtained formulas were compared with the experimental drying curves, which showed their satisfactory similarity.

Similar content being viewed by others

References

G. K. Filonenko, M. A. Grishin, Ya. M. Gol’denberg, and V. K. Kossek, Drying of Food Plant Materials [in Russian], Pishchevaya Promyshlennost′, Moscow (1971).

V. I. Atanazevich, Drying of Food Products [in Russian], Spravochnoe Posobie, Delhi, Moscow (2000).

T. Kudra and A. Mujumdar, Advanced Drying Technologies, Marcel Dekker, Inc., New York (2002).

Arun S. Mujumdar et al., Handbook of Industrial Drying, A. S. Mujumdar (Ed.), 3rd edn., Taylor & Francis Group (2006).

S. V. Jangam, C. L. Law, and A. S. Mujumdar (Eds.), Drying of Foods, Vegetables, and Fruits, Vol. 2, Singapore (2011).

Z. Pakowski and A. Adamski, The comparison of two models of convective drying of shrinking materials using apple tissue as an example, Dry. Technol., 25, Nos. 7–8, 1139–1147 (2007).

B. Honarvar and D. Mowla, Theoretical and experimental drying of a cylindrical sample by applying hot air and infrared radiation in an inert medium fluidized bed, Brazil. J. Chem. Eng., 29, No. 2, 231–242 (2012).

C. Martínez-Vera and M. Vizcarra-Mendoza, Fluidized bed drying simulation considering solid shrinkage, in: Proc. 6th Nordic Drying Conf., June 5–7, Copenhagen, Denmark (2013).

S. P. Rudobashta, É. M. Kartashov, and G. A. Zueva, Mathematical modeling of the process of convective drying of materials taking into account their shrinkage, J. Eng. Phys. Thermophys., 93, No. 6, 1394–1401 (2020).

A. V. Luikov, Theory of Drying [in Russian], 2nd revised and enlarged edn., Énergiya, Moscow (1968).

N. N. Sorokovaya, Yu. F. Snezhkin, R. A. Shapar’, and R. Ya. Sorokovoi, Mathematical simulation and optimization of the continuous drying of thermolabile materials, J. Eng. Phys. Thermophys., 92, No. 5, 1180–1190 (2019).

P. V. Akulich, Simulation of heat and mass transfer of droplets in drying an overheated liquid under conditions of combined energy effect, J. Eng. Phys. Thermophys., 92, No. 2, 389–397 (2019).

V. A. Sychevskii, Heat and mass transfer in convective wood-drying plants, J. Eng. Phys. Thermophys., 91, No. 3, 705–711 (2018).

É. N. Ochnev, S. P. Rudobashta, A. N. Planovskii, and V. M. Dmitriev, Zonal method for determining the dependence of mass conductivity on concentration, Teor. Osn. Khim. Tekhnol., IX, No. 4, 491–495 (1975).

S. P. Rudobashta, Mass Transfer in Systems with a Solid Phase [in Russian], Khimiya, Moscow (1980).

S. P. Rudobashta and V. M. Dmitriev, Kinetics and apparatus-technological arrangement of convective drying of disperse polymer materials, J. Eng. Phys. Thermophys., 78, No. 3, 463–473 (2005).

S. P. Rudobashta, G. A. Zueva, E. A. Muravleva, and V. M. Dmitriev, Mass conductivity of capillary-porous colloidal materials subjected to convective drying, J. Eng. Phys. Thermophys., 91, No. 4, 845–853 (2018).

S. P. Rudobashta, A. S. Stolbova, and V. M. Dmitriev, Shrinkage of sliced carrots during drying, in: Proc. 7th Int. Sci.-Pract. Conf. “Modern Energy-Saving Thermal Technologies (Drying and Thermal Processes), SETT-2020” dedicated to the 110 anniversary of the birth of Academician A. V. Luikov, October 13–15, 2020, pp. 189–192.

S. P. Rudobashta, S. P. Grabov, and V. M. Dmitriev, Shrinkage of sliced carrots during drying, in: Proc 7th Int. Sci.-Pract. Conf. “Modern Energy-Saving Thermal Technologies (Drying and Thermal Processes), SETT-2020” dedicated to the 110 anniversary of the birth of Academician A. V. Luikov, October 13–15, 2020, pp. 187–189.

S. P. Rudobashta and É. M. Kartashov, Chemical Technology: Diffusion Processes, in 2 parts. Pt. 1, 3rd revised and enlarged edn., Yurait, Moscow (2018).

S. P. Rudobashta and É. M. Kartashov, Chemical Technology: Diffusion Processes, in 2 parts. Pt. 2, 3rd revised and enlarged edn., Yurait, Moscow (2018).

S. P. Rudobashta, S. P. Zueva, V. M. Dmitriev, and N. A. Zuev, Mass conduction during drying of colloidal capillary-porous materials, Izv. Vyssh. Uchebn. Zaved., Khim. Khim. Tekhnol., 57, Issue 1, 103–107 (2014).

H. Tavakolipour, A. A. Kalbasi, and A. Basiri, Effect of drying parameters on quality index of Damghan pistachio and determination of effective diffusion indexes at modified conditions of this process, J. Food Sci. Technol., 5, No. 4, 47–56 (2008).

O. Sobukola, Effect of pre-treatment on the drying characteristics and kinetics of okra (Abelmoschus esculetus L. Moench) slices, Int. J. Food Eng., 5, No. 2, 1–22 (2009).

I. Doymaz, Drying kinetics of white mulberry, J. Food Eng., 61, 341–346 (2004).

J. M. F. Faustino, M. J. Barroca, and R. P. F. Guine, Study of the drying kinetics of green bell pepper and chemical characterization, Food Bioprod. Process., 85, No. 3, 163–170 (2007).

F. Khanzadeh, H. Tavakolipour, and F. Rahmani, Convection drying kinetics of asian white radish (Raphanus sativus L.) slices, in: Proc 17th Int. Drying Symp. IDS 2010, October 3–6, Magdeburg, Germany (2010), pp. 552–558.

M. Aghamasihi, I. J. Khazaei, and A. A. S. Akmal, A new way to produce dietary potato chips: drying the potato steamed crisps in hot air, in: Proc. XIII Polish Drying Symp., September 5–6, Szczecin–Kołobrzeg (2013).

Hii Ching Lik and Cobham E. Itam, Convective air drying of raw and cooked chicken meat, in: Proc. XIII Polish Drying Symp., September 5–6, Szczecin–Kołobrzeg (2013).

O. Alves-Filho, W. Senadeera, and T. Eikevik, Influence of drying conditions on the moisture diffusion during single stage and two stage fluidized bed drying of bovine intestine for pet food, in: Proc. 6th Nordic Drying Conf., June 5–7, Copenhagen, Denmark (2013).

K. Mukhatov and O. Alves-Filho, Study of the effect of drying conditions in atmospheric heat pump drying of green peas, in: Proc. 6th Nordic Drying Conf., June 5–7, Copenhagen, Denmark, (2013).

R. Adamski, A. Adamska, and Z. Pakowski, Identification of moisture transport coefficients in unsaturated material during convective drying of apple tissue, in: Proc. 6th European Drying Conf. “EuroDrying’2017”, June 19–21, Liege, Belgium (2017), pp. 27–28.

F. Vallespir, O. Rodriguez, J. Carcel, A. Femenia, and S. Simal, Intensification of beetroot and eggplant convective drying by freezing pre-treatments, in: Proc. 6th European Drying Conf. “EuroDrying’2017”, June 19–21, Liege, Belgium (2017), pp. 83–84.

D. Castillo, A. Mulet, S. Simal, J. Fernandez-Salguero, J. V. Garcia-Perez, and J. A. Carcel, Ultrasonically assited hot air drying of pepper influence on drying kinetics, in: Proc. 6th European Drying Conf. “EuroDrying’2017”, June 19–21, Liege, Belgium (2017), pp. 156–157.

A. S. Ginzburg (Ed.), Thermophysical Characteristics of Food Products and Materials, Texbook, Pischevaya Promyshlennost’, Moscow (1975).

A. S. Kholmanskii, A. Z. Tilov, and E. Yu. Sorokina, Physical and chemical modeling of the process of drying vegetables and fruits, Sovr. Probl. Nauki. Obrazov., 5, 85–92 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Inzhenerno-Fizicheskii Zhurnal, Vol. 95, No. 6, pp. 1381–1389, November–December, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rudobashta, S.P., Dmitriev, V.M. Investigation of the Diffusion Properties of Plant Capillary-Porous Colloidal Materials with Regard to Their Shrinkage. J Eng Phys Thermophy 95, 1357–1365 (2022). https://doi.org/10.1007/s10891-022-02604-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10891-022-02604-w