Abstract

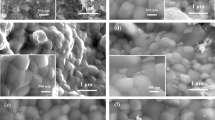

In order to synthesize nanocrystalline MoSi2, pure molybdenum and silicone powders were milled using an attritor mill with the molar ratio of Mo:Si being equal to 1:2. Mechanically alloyed (MAed) powders were heated in an atmosphere controlled furnace at various temperatures and holding times. The nanopowder characteristics were evaluated by field emission scanning electron microscopy, X-ray diffraction technique, and differential thermal analysis. The obtained results were compared for all prepared samples. The results did not confirm the presence of any related intermetallics after MA. However, Mo5Si3 was formed during heating at 900 °C. An increase in temperature caused the enhancement of the volume fraction of Mo5Si3 and formation of MoSi2. Further heating at 1,100 °C caused the enhancement of the volume fraction of MoSi2, while that of Mo5Si3 was decreased, as during heating at 1,100 °C for 7 h the volume fraction of Mo5Si3 was negligible.

Similar content being viewed by others

References

R. Darolia, J. Lewandowski, C. Liu, P. Martin, D. Miracle, and M. Nathal Structural Intermetallics (The Minerals Metals and Materials Society, USA, 1993).

M. Yamaguchi, H. Inui, and K. Ito (2000). High-temperature structural intermetallics. Acta Mater. 48, 307–322.

F. Chu, M. Lei, S. Maloy, J. Petrovic, and T. Mitchell (1996). Elastic properties of C40 transition metal disilicides. Acta Mater. 44, 3035–3048.

H. Okamoto Desk Handbook: Phase Diagrams for Binary Alloys, 2nd ed (ASM International, USA, 2010).

A. Vasudevan and J. Petrovic (1992). A comparative overview of molybdenum disilicide composites. Mater. Sci. Eng. A 155, 1–17.

Z. Yao, J. Stiglich, and T. Sudarshan (1999). Molybdenum silicide based materials and their properties. J. Mater. Eng. Perform. 8, 291–304.

E. Courtright (1999). A comparison of MoSi2 matrix composites with other silicon-base composite systems. Mater. Sci. Eng. A 261, 53–63.

D. Mason and D. Van Aken (1995). On the creep of directionally solidified MoSi2–Mo5Si3 eutectics. Acta Metall. Mater. 43, 1201–1210.

D. Mason and D. Van Aken (1993). The effect of microstructural scale on hardness of MoSi2–Mo5Si3 eutectics. Scripta Metall. Mater. 28, 185–189.

H. Zhang, S. Tang, J. Yan, and C. Zhang (2008). Fabrication and wear characteristics of MoSi2 matrix composites reinforced by La2O3 and Mo5Si3. Int. J. Refract. Met. H. 26, 115–119.

P. Peralta, R. Dickerson, J. Michael, K. McClellan, F. Chu, and T. Mitchell (1999). Residual thermal stresses in MoSi2–Mo5Si3 in situ composites. Mater. Sci. Eng. A 261, 261–269.

J. Schneibel and J. Sekhar (2003). Microstructure and properties of MoSi2–MoB and MoSi2–Mo5Si3 molybdenum silicides. Mater. Sci. Eng. A 340, 204–211.

R. Gibala, A. Ghosh, D. Van Aken, D. Srolovitz, A. Basu, H. Chang, D. Mason, and W. Yang (1992). Mechanical behavior and interface design of MoSi2-based alloys and composites. Mater. Sci. Eng. A 155, 147–158.

Y. Jeng and E. Lavernia (1994). Processing of molybdenum disilicide. J. Mater. Sci. 29, 2557–2571.

S. Deevi (1992). Diffusional reaction in the combustion synthesis of MoSi2. Mater. Sci. Eng. A 149, 241–251.

C. Yeh and W. Chen (2007). Combustion synthesis of MoSi2 and MoSi2–Mo5Si3 composites. J. Alloy. Compd. 438, 165–170.

J. Subrahmanyam (1994). Combustion synthesis of MoSi2–Mo5Si3 composites. J. Mater. Res. 9, 2620–2626.

J. Yan, H. Xu, H. Zhang, and S. Tang (2009). MoSi2 oxidation resistance coatings for Mo5Si3/MoSi2 composites. Rare Met. 28, 418–422.

T. Schubert, A. Bohm, B. Kieback, M. Achtermann, and R. Scholl (2002). Effects of high energy milling on densification behaviour of Mo–Si powder mixture during pressureless sintering. Intermetallics 10, 873–878.

A. G. Heron and G. B. Schaffer (2003). Mechanical alloying of MoSi2 with ternary alloying elements. Part1: experimental. Mater. Sci. Eng. A 325, 105–111.

M. Zakeri, R. Yazdani, M. H. Enayati, and M. R. Rahimpour (2005). Synthesis of nanocrystalline MoSi2 by mechanical alloying. J. Alloy. Compd. 403, 258–261.

H. Zhang and X. Liu (2001). Analysis of milling energy in synthesis and formation mechanism of molybdenum disilicide by mechanical alloying. Int. J. Refract. Met. H. 19, 203–208.

L. Liu and K. Cui (2003). Mechanical alloying of refractory metal–silicon systems. J. Mater. Process. Tech. 138, 394–398.

M. Sannia, R. Orru, J. E. Garay, G. Cao, and Z. A. Munir (2003). Effect of phase transformation during high energy milling of field activated synthesis of dense MoSi2. J. Mater. Sci. Eng. A 345, 270–277.

H. Saage and M. Kruger (2009). Ductilization of Mo–Si solid solutions manufactured by powder metallurgy. Acta Mater. 57, 3895–3901.

L. Liu, F. Padella, W. Guo, and M. Maginit (1995). Solid state alloying reactions include by mechanical in metal–silicon systems. Acta Metall. Mater. 43, 3755–3761.

P. Feng, A. Farid, Xi Wang, I. S. Humail, and X. Qu (2008). Mechanically activated reactive synthesis of refractory molybdenum and tungsten silicides. Int. J. Refract. Met. H. 26, 173–178.

C. Suryanarayana (2001). Mechanical alloying and milling. Mater. Sci. 46, 1–184.

E. Gaffett and N. Malhouroux-Gaffet (1994). Nanocrystalline MoSi2 phase formation induced by mechanically activated annealing. J. Alloy. Compd. 205, 27–261.

S. Zamani, H. R. Bakhsheshi-Rad, A. Shokuhfar, M. R. Vaezi, M. R. Abdul Kadir, and M. R. Mohammad Shafiee (2012). Synthesis and characterisation of MoSi2–Mo5Si3 nanocomposite by mechanical alloying and heat treatment. Int. J. Refract. Met. H. 31, 234–236.

P. Kang and Z. Yin (2004). Formation mechanism and nanocrystalline phase transformation of molybdenum disilicide by mechanical alloying. Nanotechnology 15, 851–855.

S. R. Bakhshi, M. Salehi, H. Edris, and G. H. Borhani (2008). Structural evaluation of Mo–Si–B multiphase alloy during mechanical alloying and heat treatment. Powder Metall. 51, 119–124.

B. Cullity and S. Stock Elements of X-ray Diffraction (Addison-Wesley, USA, 1956).

P. Kang and Z. Yin (2003). Phase formation during annealing as-milled powders of molybdenum disilicide. Mater. Lett. 57, 4412–4417.

D. L. Zhang (1995). Phase formation during mechanical alloying of Mo and Si powders. J. Mater. Sci. Lett. 14, 1508–1511.

M. Salavati-Niasari, M. R. Loghman-Estarki, and F. Davar (2008). Contorollable synthesis of nanocrystalline CdS with different morphologies. Chem. Eng. J. 145, 346–350.

Acknowledgments

The authors would like to appreciate the financial support of department of materials engineering of Malek Ashtar University of Technology (Shahin Shahr, Isfahan, Iran).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Erfanmanesh, M., Bakhshi, S.R. Synthesis and Characterization of Nanocrystalline MoSi2 by Mechanical Alloying and Heat Treating. J Clust Sci 24, 133–143 (2013). https://doi.org/10.1007/s10876-012-0530-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10876-012-0530-7