Abstract

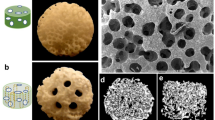

The development of a biomaterial substitute that can promote bone regeneration in massive defects has remained as a significant clinical challenge even using bone marrow cells or growth factors. Without an active, thriving cell population present throughout and stable anchored to the construct, exceptional bone regeneration does not occur. An engineered micro-channel structures scaffold within each trabecular has been designed to overcome some current limitations involving the cultivation and habitation of cells in large, volumetric scaffolds to repair massive skeletal defect. We created a scaffold with a superior fluid retention capacity that also may absorb bone marrow cells and provide growth factor-containing body fluids such as blood clots and/or serum under physiological conditions. The scaffold is composed of 3 basic structures (1) porous trabecular network (300–400 μm) similar to that of human trabecular bones, (2) micro-size channels (25–70 μm) within each trabecular septum which mimic intra-osseous channels such as Haversian canals and Volkmann’s canals with body fluid access, diffusion, nutritional supply and gas exchange, and (3) nano-size pores (100–400 nm) on the surface of each septum that allow immobilized cells to anchor. Combinatorial effects of these internal structures result in a host-adapting construct that enhances cell retention and habitation throughout the 3 cm-height and 4 cm-length bridge-shaped scaffold.

Similar content being viewed by others

References

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials. 2005;26:5474–91.

Vats A, Tolley NS, Polak JM, Gough JE. Scaffolds and biomaterials for tissue engineering: a review of clinical applications. Clin Otolaryngol Allied Sci. 2003;28:165–72.

Hutmacher DW. Scaffolds in tissue engineering bone and cartilage. Biomaterials. 2000;21:2529–43.

Arinzeh TL, Tran T, Mcalary J, Daculsi G. A comparative study of biphasic calcium phosphate ceramics for human mesenchymal stem-cell-induced bone formation. Biomaterials. 2005;26:3631–8.

Zou XH, Cai HX, Yin Z, Chen X, Jiang YZ, Hu H, Ouyang HW. A novel strategy incorporated the power of mesenchymal stem cells to allografts for segmental bone tissue engineering. Cell Transplant. 2009;18:433–41.

Ono I, Yamashita T, Jin HY, Ito Y, Hamada H, Akasaka Y, et al. Combination of porous hydroxyapatite and cationic liposomes as a vector for BMP-2 gene therapy. Biomaterials. 2004;25:4709–18.

Woodard JR, Hilldore AJ, Lan SK, Park CJ, Morgan AW, Eurell JA, et al. The mechanical properties and osteoconductivity of hydroxyapatite bone scaffolds with multi-scale porosity. Biomaterials. 2007;28:45–54.

Manjubala I, Woesz A, Pilz C, Rumpler M, Fratzl-Zelman N, Roschger P, et al. Biomimetic mineral-organic composite scaffolds with controlled internal architecture. J Mater Sci Mater Med. 2005;16:1111–9.

Unger RE, Sartoris A, Peters K, Motta A, Migliaresi C, Kunkel M, et al. Tissue-like self-assembly in cocultures of endothelial cells and osteoblasts and the formation of microcapillary like structures on three-dimensional porous biomaterials. Biomaterials. 2007;28:3965–76.

Goldstein AS, Juarez TM, Helmke CD, Gustin MC, Mikos AG. Effect of convection on osteoblastic cell growth and function in biodegradable polymer foam scaffolds. Biomaterials. 2001;22:1279–88.

Hofmann S, Hagenmüller H, Koch AM, Müller R, Vunjak-Novakovic G, Kaplan DL, et al. Control of in vitro tissue-engineered bone-like structures using human mesenchymal stem cells and porous silk scaffolds. Biomaterials. 2007;28:1152–62.

Gauthier O, Bouler JM, Aguado E, Pilet P, Daculsi G. Macroporous biphasic calcium phosphate ceramics: influence of macropore diameter and macroporosity percentage on bone ingrowth. Biomaterials. 1998;19:133–9.

Bignon A, Chouteau J, Chevalier J, Fantozzi G, Carret JP, Chavassieux P, et al. Effect of micro- and macroporosity of bone substitutes on their mechanical properties and cellular response. J Mater Sci Mater Med. 2003;14:1089–97.

Mathieu LM, Mueller TL, Bourban PE, Pioletti DP, Muller R, Manson JA. Architecture and properties of anisotropic polymer composite scaffolds for bone tissue engineering. Biomaterials. 2006;27(6):905–16.

Tsutsumi H, Shibasaki Y, Onimura K, Oishi T. Preparation of photo-patterned polymer–hydroxyapatite composites. Polymer. 2003;44(20):6297–301.

Wang Y-W, Wu Q, Chen J, Chen GQ. Evaluation of three-dimensional scaffolds made of blends of hydroxyapatite and poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) for bone reconstruction. Biomaterials. 2005;26(8):899–904.

Kim S-S, Sun Park M, Jeon O, Yong Choi C, Kim B-S. Poly(lactide-co-glycolide)/hydroxyapatite composite scaffolds for bone tissue engineering. Biomaterials. 2006;27(8):1399–409.

Mathieu LM, Mueller TL, Bourban PE, Pioletti DP, Müller R, Månson JA. Architecture and properties of anisotropic polymer composite scaffolds for bone tissue engineering. Biomaterials. 2006;27:905–16.

Wang YW, Wu Q, Chen J, Chen GQ. Evaluation of three-dimensional scaffolds made of blends of hydroxyapatite and poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) for bone reconstruction. Biomaterials. 2005;26:899–904.

Kim SS, Sun Park M, Jeon O, Yong Choi C, Kim B-S. Poly(lactide-co-glycolide)/hydroxyapatite composite scaffolds for bone tissue engineering. Biomaterials. 2006;27:1399–409.

Sachlos E, Czernuszka JT. Making tissue engineering scaffolds work. Review: the application of solid freeform fabrication technology to the production of tissue engineering scaffolds. Eur Cells Mater. 2003;5:29–40.

Hutmacher DW, Sittinger M, Risbud MV. Scaffold-based tissue engineering: rationale for computer-aided design and solid free-form fabrication systems. Trends Biotechnol. 2004;22:354–62.

Sachlos E, Czernuszka JT. Making tissue engineering scaffolds work. Review on the application of solid freeform fabrication technology to the production of tissue engineering scaffolds. Eur Cell Mater. 2003;5:29–40.

Oh DS, Kim YH, Ganbat D, Han MH, Lim PH, Back JH, et al. Bone marrow absorption and retention properties of engineered scaffolds with micro-channels and nano-pores for tissue engineering: a proof of concept. Ceram Int. 2013;39:8401–10.

COMSOL CFD Module User’s Guide. Comsol AB. 2010.

Mitton D, Cendre E, Roux JP, Arlot ME, Peix G, Rumelhart C, et al. Mechanical properties of ewe vertebral cancellous bone compared with histomorphometry and high-resolution computed tomography parameters. Bone. 1998;22(6):651–8.

Goldstein SA. The mechanical properties of trabecular bone: dependence on anatomic location and function. J Biomech. 1987;20(11–12):1055–61.

Rosenson RS, McCormick A, Uretz EF. Distribution of blood viscosity values and biochemical correlates in healthy adults. Clin Chem. 1996;42:1189–95.

Rosina J, Kvasnák E, Suta D, Kolárová H, Málek J, Krajci L. Temperature dependence of blood surface tension. Physiol Res. 2007;56:S93–8.

Cohen IM, Kundu PK. Fluid mechanics. 4th ed. Burlington; 2007. p. 765–830.

Tsuruga E, Takita H, Itoh H, Wakisaka Y, Kuboki Y. Pore size of porous hydroxyapatite as the cell-substratum controls BMP-induced osteogenesis. J Biochem. 1997;121:317–24.

Yuan H, Kurashina K, de Bruin JD, Li Y, de Groot K, Zhang X. A preliminary study on osteoinduction of two kinds of calcium phosphate ceramics. Biomaterials. 1999;20:1799–806.

Wan Y, Wang Y, Liu Z, Qu X, Han B, Bei J, Wang S. Adhesion and proliferation of OCT-1 osteoblast-like cells on micro- and nano-scale topography structured poly(l-lactide). Biomaterials. 2005;26:4453–9.

Zhao L, Mei S, Chu PK, Zhang Y, Wu Z. The influence of hierarchical hybrid micro/nano-textured titanium surface with titania nanotubes on osteoblast functions. Biomaterials. 2010;31:5072–82.

Acknowledgement

This work was partially supported by National Agenda Project (NAP) funded by Korea Research Council of Fundamental Science & Technology (P-09-JC-LU63-C01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Min-Ho Hong and Yoon Hyuk Kim are equally contributed for this work.

Rights and permissions

About this article

Cite this article

Hong, MH., Kim, Y.H., Ganbat, D. et al. Capillary action: enrichment of retention and habitation of cells via micro-channeled scaffolds for massive bone defect regeneration. J Mater Sci: Mater Med 25, 1991–2001 (2014). https://doi.org/10.1007/s10856-014-5225-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-014-5225-1