Abstract

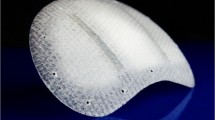

The aim of this study was to characterize the microstructure and mechanical properties of porous fiber-reinforced composites (FRC). Implants made of the FRC structures are intended for cranial applications. The FRC specimens were prepared by impregnating E-glass fiber sheet with non-resorbable bifunctional bis-phenyl glycidyl dimethacrylate and triethylene glycol dimethacrylate resin matrix. Four groups of porous FRC specimens were prepared with a different amount of resin matrix. Control group contained specimens of fibers, which were bound together with sizing only. Microstructure of the specimens was analyzed using a micro computed tomography (micro-CT) based method. Mechanical properties of the specimens were measured with a tensile test. The amount of resin matrix in the specimens had an effect on the microstructure. Total porosity was 59.5 % (median) in the group with the lowest resin content and 11.2 % (median) in the group with the highest resin content. In control group, total porosity was 94.2 % (median). Correlations with resin content were obtained for all micro-CT based parameters except TbPf. The tensile strength of the composites was 21.3 MPa (median) in the group with the highest resin content and 43.4 MPa (median) in the group with the highest resin content. The tensile strength in control group was 18.9 MPa (median). There were strong correlations between the tensile strength of the specimens and most of the micro-CT based parameters. This experiment suggests that porous FRC structures may have the potential for use in implants for cranial bone reconstructions, provided further relevant in vitro and in vivo tests are performed.

Similar content being viewed by others

References

Vallittu PK. Flexural properties of acrylic resin polymers reinforced composite with unidirectional and woven glass fibers. J Prosthet Dent. 1999;81:318–26.

Vallittu PK, Sevelius C. Resin-bonded, glass fiber-reinforced composite fixed partial dentures: a clinical study. J Prosthet Dent. 2000;84:413–8.

Tuusa SM, Peltola MJ, Tirri T, Lassila LV, Vallittu PK. Frontal bone defect repair with experimental glass-fiber-reinforced composite with bioactive glass granule coating. J Biomed Mater Res B Appl Biomater. 2007;82:149–55.

Tuusa SM-R, Peltola MJ, Tirri T, Puska MA, Röyttä M, Aho H, Sandholm J, Lassila LVJ, Vallittu PK. Reconstruction of critical size calvarial bone defects in rabbits with glass-fibre-reinforced composite with bioactive glass granule coating. J Biomed Mater Res B Appl Biomater. 2007;82:149–55.

Aitasalo K, Rekola J, Piitulainen J, Vallittu PK. Craniofacial bone reconstruction with a novel bioactive composite implant. J Neurol Surg B. 2012;73:A099.

Aitasalo KM, Piitulainen JM, Rekola J, Vallittu PK. Craniofacial bone reconstruction with bioactive fibre-reinforced composite implant. Head Neck. 2013 in press.

Nganga S, Zhang D, Moritz N, Vallittu PK, Hupa L. Multi-layer porous fiber-reinforced composites for implants: in vitro calcium phosphate formation in the presence of bioactive glass. Dent Mater. 2012;28(11):1134–45.

ASTM D638-00. Standard Test Method for Tensile Properties of Plastics. The American Society for Testing and Materials; 2000.

ISO 527. Plastics - Determination of tensile properties. The International Organization for Standardization; 1997.

Hulbert SF, Young FA, Mathews RS, Klawitter JJ, Talbert CD, Stelling FH. Potential of ceramic materials as permanently implantable skeletal prostheses. J Biomed Mater Res. 1970;4:433–56.

Kienapfel H, Sprey C, Wilke A, Griss P. Implant fixation by bone ingrowth. J Arthroplasty. 1999;14:355–68.

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials. 2005;26:5474–91.

Jones JR, Atwood RC, Poologasundarampillai G, Yue S, Lee PD. Quantifying the 3D macrostructure of tissue scaffolds. J Mater Sci Mater Med. 2009;2:463–71.

Itälä AI, Ylänen HO, Ekholm C, Karlson KH, Aro HT. Pore diameter of more than 100 μm is not requisite for bone ingrowth in rabbits. J Biomed Mater Res. 2001;58(6):679–83.

Feldkamp LA, Goldstein SA, Parfitt AM, Jesion G, Kleerekoper M. The direct examination of three-dimensional bone architecture in vitro by computed tomography. J Bone Miner Res. 1989;4:3–11.

Parfitt A, Drezner M, Glorieux F, Kanis J, Recker R. Bone histomorphometry: standardization of nomenclature, symbols and units. J Bone Miner Res. 1987;2:595–610.

Odgaard A, Gundersen HJ. Quantification of connectivity in cancellous bone, with special emphasis on 3D reconstructions. Bone. 1993;14(2):173–82.

Odgaard A. Three-dimensional methods for quantification of cancellous bone architecture. Bone. 1997;20(4):315–28.

Hildebrand T, Rüegsegger P. A new method for model-independent assesment of thickness in three-dimensional images. J Microscopy. 1997;185(1):67–75.

Goulet RW, Goldstein SA, Ciarelli MJ, Kuhn JL, Brown MB, Feldkamp LA. The relationship between the structural and orthogonal compressive properties of trabecular bone. J Biomech. 1994;27(4):375–89.

Ho ST, Hutmacher DW. A comparison of micro CT with other techniques used in the characterization of scaffolds. Biomaterials. 2006;27:1362–76.

Jones AC, Milthorpe B, Averdunk H, Limaye A, Senden TJ, Sakellariou A, et al. Analysis of 3D bone ingrowth into polymer scaffolds via micro-computed tomography imaging. Biomaterials. 2004;25:4947–54.

Otsuki B, Takemoto M, Fujibayashi S, Neo M, Kokubo T, Nakamura T. Pore throat size and connectivity determine bone and tissue ingrowth into porous implants: three-dimensional micro-CT based structural analyses of porous bioactive titanium implants. Biomaterials. 2006;27:5892–900.

Moore MJ, Jabbari E, Ritman EL, Lu L, Currier BL, Windebank AJ, Yaszemski MJ. Quantitative analysis of interconnectivity of porous biodegradable scaffolds with micro-computed tomography. J Biomed Mater Res. 2004;71A(2):258–67.

Weber E, Fernandez M, Wapner P, Hoffman W. Comparison of X-ray micro-tomography measurements of densities and porosity principally to values measured by mercury porosimetry for carbon–carbon composite. Carbon. 2010;48:2151–8.

Spowage AC, Shacklock AP, Malcom AA, May SL, Tong L, Kennedy AR. Development of characterization methodologies for macroporous materials. J Porous Mater. 2006;13:431–8.

Chu TMG, Orton DG, Hollister SJ, Feinberg SE, Halloran JW. Mechanical and in vivo performance of hydroxyapatite implants with controlled architectures. Biomaterials. 2002;23:1283–93.

Davis JR. Tensile testing. 2nd ed. ASM International; 2004.

McElhaney JH, Fogle JL, Melvin JW, Haynes RR, Roberts VL, Alem NM. Mechanical properties of cranial bone. J Biomech. 1970;3(5):495–511.

Wood JL. Dynamic response of human cranial bone. J Biomech. 1971;4(1):1–12.

Keller TS, Liebschner MA. Tensile and compression testing of bone. In: An YH, Draughn RA, eds. Mechanical testing of bone and the bone-implant interface. CRC Press; 1999. pp 175–205.

Motherway JA, Verschueren P, Van der Perre G, Vander Sloten J, Gilchrist MD. The mechanical properties of cranial bone: the effect of loading rate and cranial sampling position. J Biomech. 2009;42(13):2129–35.

An YH. Mechanical properties of bone. In: An YH, Draughn RA, editors. Mechanical testing of bone and the bone-implant interface. CRC Press; 1999. pp 41–63.

Lethaus B, Laak MP, Leaven P, Beerens M., Koper D, Poukens J, Kessler P. A treatment algorithm for patient with large skull bone defect and first results. J Craniomaxillofac. Surg. 2011;39(6):435–40.

Acknowledgments

This study was supported by TEKES (MIKAMA-project, grant #40095/07). AY-S whishes to thank the laboratory personnel of Turku Clinical Biomaterials Centre -TCBC for their help during the laboratory work. Study belongs to the activity of BioCity Turku Biomaterialds Research Program (www.biomaterials.utu.fi). In the memory of Dr. Matti Peltola, DDS, MD, PhD 1961–2011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ylä-Soininmäki, A., Moritz, N., Lassila, L.V.J. et al. Characterization of porous glass fiber-reinforced composite (FRC) implant structures: porosity and mechanical properties. J Mater Sci: Mater Med 24, 2683–2693 (2013). https://doi.org/10.1007/s10856-013-5023-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-013-5023-1