Abstract

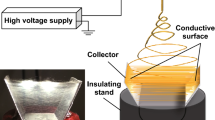

A new electrospinning apparatus was developed to generate nanofibrous materials with improved organizational control. The system functions by oscillating the deposition signal (ODS) of multiple collectors, allowing significantly improved nanofiber control by manipulating the electric field which drives the electrospinning process. Other electrospinning techniques designed to impart deposited fiber organizational control, such as rotating mandrels or parallel collector systems, do not generate seamless constructs with high quality alignment in sizes large enough for medical devices. In contrast, the ODS collection system produces deposited fiber networks with highly pure alignment in a variety of forms and sizes, including flat (8 × 8 cm2), tubular (1.3 cm diameter), or rope-like microbundle (45 μm diameter) samples. Additionally, the mechanism of our technique allows for scale-up beyond these dimensions. The ODS collection system produced 81.6 % of fibers aligned within 5° of the axial direction, nearly a four-fold improvement over the rotating mandrel technique. The meshes produced from the 9 % (w/v) fibroin/PEO blend demonstrated significant mechanical anisotropy due to the fiber alignment. In 37 °C PBS, aligned samples produced an ultimate tensile strength of 16.47 ± 1.18 MPa, a Young’s modulus of 37.33 MPa, and a yield strength of 7.79 ± 1.13 MPa. The material was 300 % stiffer when extended in the direction of fiber alignment and required 20 times the amount of force to be deformed, compared to aligned meshes extended perpendicular to the fiber direction. The ODS technique could be applied to any electrospinnable polymer to overcome the more limited uniformity and induced mechanical strain of rotating mandrel techniques, and greatly surpasses the limited length of standard parallel collector techniques.

Similar content being viewed by others

References

Shenoy S, Bates W, Frisch H, Wnek G. Role of chain entanglements on fiber formation during electrospinning of polymer solutions: good solvent, non-specific polymer? polymer interaction limit. Polymer. 2005;46:3372–84.

Deitzel JM, Kleinmeyer JD, Hirvonen JK, Tan NC. Controlled deposition of electrospun poly(ethylene oxide) fibers. Polymer. 2001;42:8163–70.

Angammana C, Jayaram SH. The effects of electric field on the multijet electrospinning process and fiber morphology. Ind Appl IEEE. 2011;47:1028–35.

Schreuder-Gibson H, Gibson P, Tsai P, Gupta P, Wilkes G. Cooperative charging effects of fibers from electrospinning of electrically dissimilar polymers. Int Nonwovens J. 2005;13:39–45.

Reneker DH, Yarin AL, Fong H, Koombhongse S. Bending instability of electrically charged liquid jets of polymer solutions in electrospinning. J Appl Phys. 2000;87:4531.

Yarin AL, Koombhongse S, Reneker DH. Bending instability in electrospinning of nanofibers. J Appl Phys. 2001;89:3018.

Gaumer J, Prasad A, Lee D, Lannutti J. Structure–function relationships and source-to-ground distance in electrospun polycaprolactone. Acta Biomater. 2009;5:1552–61.

Stachewicz U, Peker I, Tu W, Barber AH. Stress delocalization in crack tolerant electrospun nanofiber networks. ACS Appl Mater Interfaces. 2011;3:1991–6.

Beachley V, Wen X. Effect of electrospinning parameters on the nanofiber diameter and length. Mater Sci Eng C. 2009;29:663–8.

Saraf A, Lozier G, Haesslein A, Kasper FK, Raphael RM, Baggett LS, Mikos AG. Fabrication of nonwoven coaxial fiber meshes by electrospinning. Tissue Eng C. 2009;15:333–44.

Thakur RA, Florek CA, Kohn J, Michniak BB. Electrospun nanofibrous polymeric scaffold with targeted drug release profiles for potential application as wound dressing. Int J Pharm. 2008;364:87–93.

Barnes CP, Pemble CW, Brand DD, Simpson DG, Bowlin GL. Cross-linking electrospun type II collagen tissue engineering scaffolds with carbodiimide in ethanol. Tissue Eng. 2007;13:1593–605.

Zhang X, Wang X, Keshav V, Wang X, Johanas JT, Leisk GG, Kaplan DL. Dynamic culture conditions to generate silk-based tissue-engineered vascular grafts. Biomaterials. 2009;30:3213–23.

Sell S A, Francis M P, Garg K, McClure M J, Simpson D G and Bowlin G L. Cross-linking methods of electrospun fibrinogen scaffolds for tissue engineering applications. Biomed. Mater. 2008;3: 045001.

Yoshimatsu K, Ye L, Lindberg J, Chronakis IS. Selective molecular adsorption using electrospun nanofiber affinity membranes. Biosens Bioelectron. 2008;23:1208–15.

Cai Z-X, Mo X-M, Zhang K-H, Fan L-P, Yin A-L, He C-L, Wang H-S. Fabrication of chitosan/silk fibroin composite nanofibers for wound-dressing applications. Int J Mol Sci. 2010;11:3529–39.

Kempf M, Miyamura Y, Liu P-Y, Chen AC-H, Nakamura H, Shimizu H, Tabata Y, Kimble RM, McMillan JR. A denatured collagen microfiber scaffold seeded with human fibroblasts and keratinocytes for skin grafting. Biomaterials. 2011;32:4782–92.

Lee H, Yeo M, Ahn S, Kang D-O, Jang CH, Lee H, Park G-M, Kim GH. Designed hybrid scaffolds consisting of polycaprolactone microstrands and electrospun collagen-nanofibers for bone tissue regeneration. J Biomed Mater Res B. 2011;97:263–70.

Ahmad Z, Stride E, Edirisinghe M. Novel preparation of transdermal drug-delivery patches and functional wound healing materials. J Drug Target. 2009;17:724–9.

Yao L, O’Brien N, Windebank A, Pandit A. Orienting neurite growth in electrospun fibrous neural conduits. J Biomed Mater Res B. 2009;90:483–91.

Weber N, Lee Y-S, Shanmugasundaram S, Jaffe M, Arinzeh TL. Characterization and in vitro cytocompatibility of piezoelectric electrospun scaffolds. Acta Biomater. 2010;6:3550–6.

Ladd MR, Lee SJ, Stitzel JD, Atala A, Yoo JJ. Co-electrospun dual scaffolding system with potential for muscle–tendon junction tissue engineering. Biomaterials. 2011;32:1549–59.

Ma Z, Chen F, Zhu Y-J, Cui T, Liu X-Y. Amorphous calcium phosphate/poly(d, l-lactic acid) composite nanofibers: electrospinning preparation and biomineralization. J Colloid Interface Sci. 2011;359:371–9.

Murugan R, Ramakrishna S. Design strategies of tissue engineering scaffolds with controlled fiber orientation. Tissue Eng. 2007;13:1845–66.

Aviss KJ, Gough JE, Downes S. Aligned electrospun polymer fibres for skeletal muscle regeneration. Eur Cells Mater. 2010;19:193–204.

Xie J, MacEwan MR, Ray WZ, Liu W, Siewe DY, Xia Y. Radially aligned, electrospun nanofibers as dural substitutes for wound closure and tissue regeneration applications. ACS Nano. 2010;4:5027–36.

Xie J, Li X, Xia Y. Putting electrospun nanofibers to work for biomedical research. Macromol Rapid Commun. 2008;29:1775–92.

Xie J, Li X, Lipner J, Manning CN, Schwartz AG, Thomopoulos S, Xia Y. “Aligned-to-random” nanofiber scaffolds for mimicking the structure of the tendon-to-bone insertion site. Nanoscale. 2010;2:923–6.

Wolfe PS, Madurantakam P, Garg K, Sell S, Beckman MJ, Bowlin GL. Evaluation of thrombogenic potential of electrospun bioresorbable vascular graft materials: acute monocyte tissue factor expression. J Biomed Mater Res A. 2010;92:1321–8.

McClure MJ, Sell S, Simpson DG, Walpoth BH, Bowlin GL. A three-layered electrospun matrix to mimic native arterial architecture using polycaprolactone, elastin, and collagen: a preliminary study. Acta Biomater. 2010;6:2422–33.

Wu H, Fan J, Chu C-C, Wu J. Electrospinning of small diameter 3-D nanofibrous tubular scaffolds with controllable nanofiber orientations for vascular grafts. J Mater Sci Mater Med. 2010;21:3207–15.

Drilling S, Gaumer J, Lannutti J. Fabrication of burst pressure competent vascular grafts via electrospinning: effects of microstructure. J Biomed Mater Res A. 2009;88:923–34.

Liu X, Chen J, Gilmore KJ, Higgins MJ, Liu Y, Wallace GG. Guidance of neurite outgrowth on aligned electrospun polypyrrole/poly(styrene-beta-isobutylene-beta-styrene) fiber platforms. J Biomed Mater Res A. 2010;94:1004–11.

Griffin J, Delgado-Rivera R, Meiners S, Uhrich KE. Salicylic acid-derived poly(anhydride-ester) electrospun fibers designed for regenerating the peripheral nervous system. J Biomed Mater Res A. 2011;97:230–42.

Ahmad Z, Nangrejo M, Edirisinghe M, Stride E, Colombo P, Zhang HB. Engineering a material for biomedical applications with electric field assisted processing. Appl Phys A. 2009;97:31–7.

Lovett M, Cannizzaro C, Daheron L, Messmer B. Silk fibroin microtubes for blood vessel engineering. Biomaterials. 2007;28:5271–9.

Lu S, Wang X, Lu Q, Zhang X, Kluge Ja, Uppal N, Omenetto F, Kaplan DL. Insoluble and flexible silk films containing glycerol. Biomacromolecules. 2010;11:143–50.

Jin H-J, Fridrikh SV, Rutledge GC, Kaplan DL. Electrospinning Bombyx mori silk with poly(ethylene oxide). Biomacromolecules. 2002;3:1233–9.

Zhang X, Reagan MR, Kaplan DL. Electrospun silk biomaterial scaffolds for regenerative medicine. Adv Drug Deliv Rev. 2009;61:988–1006.

Jin H. Human bone marrow stromal cell responses on electrospun silk fibroin mats. Biomaterials. 2004;25:1039–47.

Wang H, Zhang Y, Shao H, Hu X. Electrospun ultra-fine silk fibroin fibers from aqueous solutions. J Mater Sci. 2005;40:5359–63.

Wang S, Zhang Y, Wang H, Yin G, Dong Z. Fabrication and properties of the electrospun polylactide/silk fibroin-gelatin composite tubular scaffold. Biomacromolecules. 2009;10:2240–4.

Wei K, Li Y, Kim K-O, Nakagawa Y, Kim B-S, Abe K, Chen G-Q, Kim I-S. Fabrication of nano-hydroxyapatite on electrospun silk fibroin nanofiber and their effects in osteoblastic behavior. J Biomed Mater Res A. 2011;97:272–80.

Min B-M, Lee G, Kim SH, Nam YS, Lee TS, Park WH. Electrospinning of silk fibroin nanofibers and its effect on the adhesion and spreading of normal human keratinocytes and fibroblasts in vitro. Biomaterials. 2004;25:1289–97.

Kumar A, Wei M, Barry C, Chen J, Mead J. Controlling fiber repulsion in multijet electrospinning for higher throughput. Macromol Mater Eng. 2010;295:701–8.

Timnak A, Gharebaghi FY, Shariati RP, Bahrami SH, Javadian S, Emami SH, Shokrgozar MA. Fabrication of nano-structured electrospun collagen scaffold intended for nerve tissue engineering. J Mater Sci Mater Med. 2011;22:1555–67.

Nandakumar A, Fernandes H, de Boer J, Moroni L, Habibovic P, van Blitterswijk Ca. Fabrication of bioactive composite scaffolds by electrospinning for bone regeneration. Macromol Biosci. 2010;10:1365–73.

Ramakrishna S. An introduction to electrospinning and nanofibers. Singapore: World Scientific Pub Co Inc.; 2005.

Vaquette C, Cooper-White J. Increasing electrospun scaffold pore size with tailored collectors for improved cell penetration. Acta Biomater. 2011;7:2544–57.

Kundu J, Dewan M, Ghoshal S, Kundu SC. Mulberry non-engineered silk gland protein vis-à-vis silk cocoon protein engineered by silkworms as biomaterial matrices. J Mater Sci Mater Med. 2008;19:2679–89.

Rajkhowa R, Levin B, Redmond SL, Li LH, Wang L, Kanwar JR, Atlas MD, Wang X. Structure and properties of biomedical films prepared from aqueous and acidic silk fibroin solutions. J Biomed Mater Res A. 2011;97A:37–45.

Tong H-W, Wang M, Lu WW. Electrospinning and evaluation of PHBV-based tissue engineering scaffolds with different fibre diameters, surface topography and compositions. J Biomater Sci Polym Ed. 2011;23:779–806.

Li X, Xie J, Lipner J, Yuan X, Thomopoulos S, Xia Y. Nanofiber scaffolds with gradations in mineral content for mimicking the tendon-to-bone insertion site. Nano Lett. 2009;9:2763–8.

Acknowledgments

Supported by National Science Foundation award CBET-0932456, and partially by NIH awards EY020856 and EB002520, and AFOSR award FA9550-10-1-0172. We thank Dr. Robert White for contributing microscale profilometry measurements, and Dr. Ethan Golden for his assistance in design and fabrication.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jose, R.R., Elia, R., Firpo, M.A. et al. Seamless, axially aligned, fiber tubes, meshes, microbundles and gradient biomaterial constructs. J Mater Sci: Mater Med 23, 2679–2695 (2012). https://doi.org/10.1007/s10856-012-4739-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-012-4739-7