Abstract

The high-velocity suspension flame spraying technique (HVSFS) was employed in order to deposit 45S5 bioactive glass coatings onto titanium substrates, using a suspension of micron-sized glass powders dispersed in a water + isopropanol mixture as feedstock. By modifying the process parameters, five coatings with different thickness and porosity were obtained. The coatings were entirely glassy but exhibited a through-thickness microstructural gradient, as the deposition mechanisms of the glass droplets changed at every torch cycle because of the increase in the system temperature during spraying. After soaking in simulated body fluid, all of the coatings were soon covered by a layer of hydroxyapatite; furthermore, the coatings exhibited no cytotoxicity and human osteosarcoma cells could adhere and proliferate well onto their surfaces. HVSFS-deposited 45S5 bioglass coatings are therefore highly bioactive and have potentials as replacement of conventional hydroxyapatite in order to favour osseointegration of dental and prosthetic implants.

Similar content being viewed by others

References

Cao W, Hench LL. Bioactive materials. Ceram Int. 1996;22:493–507.

Hench LL. Bioceramics. J Am Ceram Soc. 1998;81:1705–28.

Gross KA, Berndt CC. Biomedical application of apatites. In: Kohn MJ, Rakovan J, Hughes JM, editors. Phosphates: geochemical, geobiological, materials importance—reviews in mineralogy, geochemistry, vol. 48. Washington DC, USA: Mineralogical Society of America; 2002. p. 631–72.

Liu X, Chu PK, Ding C. Surface modification of titanium titanium alloys, and related materials for biomedical applications. Mater Sci Eng R. 2004;47:49–121.

Sun L, Berndt CC, Gross KA, Kucuk A. Material fundamentals and clinical performance of plasma-sprayed hydroxyapatite coatings: a review. J Biomed Mater Res. 2001;58:570–92.

García C, Ceré S, Durán A. Bioactive coatings deposited on titanium alloys. J Non-Cryst Solids. 2006;352:3488–95.

Kačiulis S, Mattogno G, Pandolfi L, Cavalli M, Gnappi G, Montenero A. XPS study of apatite-based coatings prepared by sol–gel technique. Appl Surf Sci. 1999;151:1–5.

Gyorgy E, Grigorescu S, Socol G, Mihailescu IN, Janackovic D, Dindune A, Kanepe Z, Palcevskis E, Zdrentu EL, Petrescu SM. Bioactive glass and hydroxyapatite thin films obtained by pulsed laser deposition. Appl Surf Sci. 2007;253:7981–6.

Yang Y, Kim K-H, Ong JL. A review on calcium phosphate coatings produced using a sputtering process—an alternative to plasma spraying. Biomaterials. 2005;26:327–37.

Trommer RM, Santos LA, Bergmann CP. Alternative technique for hydroxyapatite coatings. Surf Coat Technol. 2007;201:9587–93.

Paital SR, Dahotre NB. Calcium phosphate coatings for bio-implant applications: materials performance factors, and methodologies. Mater Sci Eng R. 2009;66:1–70.

de Groot K, Wolke JGC, Jansen JA. Calcium phosphate coatings for medical implants. Proc Inst Mech Eng H J Eng Med. 1998;212:137–47.

Herman H, Sampath S, McCune R. Thermal spraying: current status and future trends. Mater Res Soc Bull. 2000;25(7):17–25.

Sun L, Berndt CC, Khor KA, Cheang NH, Gross KA. Surface characteristics and dissolution behavior of plasma-sprayed hydroxyapatite coating. J Biomed Mater Res. 2002;62:228–36.

Dyshlovenko S, Pawlowski L, Roussel P, Murano D, Le Maguer A. Relationship between plasma spray operational parameters and microstructure of hydroxyapatite coatings and powder particles sprayed into water. Surf Coat Technol. 2006;200:3845–55.

Dyshlovenko S, Pawlowski L, Pateyron B, Smurov I, Harding JH. Modelling of plasma particle interactions and coating growth for plasma spraying of hydroxyapatite. Surf Coat Technol. 2006;200:3757–69.

Heimann RB. Thermal spraying of biomaterials. Surf Coat Technol. 2006;201:2012–9.

Pierlot C, Pawlowski L, Tomaszek R, Dyshlovenko S, Bigan M. Interdependence of different properties of hydroxyapatite coatings and powders plasma sprayed into water. Chemom Intell Lab Syst. 2007;86:153–8.

Dyshlovenko S, Pierlot C, Pawlowski L, Tomaszek R, Chagnon P. Experimental design of plasma spraying and laser treatment of hydroxyapatite coatings. Surf Coat Technol. 2006;201:2054–60.

Yang C-W, Lee T-M, Lui T-S, Chang E. Effect of post vacuum heating on the microstructural feature and bonding strength of plasma-sprayed hydroxyapatite coatings. Mater Sci Eng C. 2006;26:1395–400.

Lugscheider E, Knepper M, Nyland A. Characterization of thermal sprayed bioactive coatings. Colloids Surf B. 1996;6:1–7.

Gabbi C, Cacchioli A, Locardi B, Guadagnino E. Bioactive glass coating: physicochemical aspects and biological findings. Biomaterial. 1995;16:515–20.

Schrooten J, Helsen JA. Adhesion of bioactive glass coating to Ti6Al4V oral implant. Biomaterial. 2000;21:1461–9.

Lee TM, Chang E, Wang BC, Yang CY. Characteristics of plasma-sprayed bioactive glass coatings on Ti–6A1–4V alloy: an in vitro study. Surf Coat Technol. 1996;79:170–7.

Oliva A, Salerno A, Locardi B, Riccio V, Della Ragione F, Iardino P, Zappia V. Behaviour of human osteoblasts cultured on bioactive glass coatings. Biomaterial. 1998;19:1019–25.

Foppiano S, Marshall SJ, Marshall GW, Saiz E, Tomsia AP. Bioactive glass coatings affect the behavior of osteoblast-like cells. Acta Biomater. 2007;3:765–71.

Lopez-Estebana S, Saiz E, Fujino S, Oku T, Suganuma K, Tomsia AP. Bioactive glass coatings for orthopedic metallic implants. J Eur Ceram Soc. 2003;23:2921–30.

Bolelli G, Lusvarghi L, Manfredini T, Siligardi C. Influence of the manufacturing process on the crystallization behavior of a CZS glass system. J Non-Cryst Solids. 2005;351:2537–46.

Höland Wolfram. Biocompatible and bioactive glass-ceramics—state of the art and new directions. J Non-Cryst Solids. 1997;219:192–7.

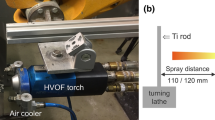

Killinger A, Kuhn M, Gadow R. High-velocity suspension flame spraying (HVSFS), a new approach for spraying nanoparticles with hypersonic speed. Surf Coat Technol. 2006;201:1922–9.

Rauch J, Bolelli G, Killinger A, Gadow R, Cannillo V, Lusvarghi L. Advances in high velocity suspension flame spraying (HVSFS). Surf Coat Technol. 2009;203:2131–8.

Gadow R, Killinger A, Rauch J. New results in high velocity suspension flame spraying (HVSFS). Surf Coat Technol. 2008;202:4329–36.

Bolelli G, Rauch J, Cannillo V, Killinger A, Lusvarghi L, Gadow R. Investigation of high-velocity suspension flame sprayed (HVSFS) glass coatings. Mater Lett. 2008;62:2772–5.

Cannillo V, Pierli F, Sampath S, Siligardi C. Thermal and physical characterisation of apatite/wollastonite bioactive glass–ceramics. J Eur Ceram Soc. 2007;27:4575–88.

Bolelli G, Cannillo V, Gadow R, Killinger A, Lusvarghi L, Rauch J. Microstructural and in vitro characterisation of high-velocity suspension flame sprayed (HVSFS) bioactive glass coatings. J Eur Ceram Soc. 2009;29:2249–57.

Hench LL. Bioceramics: from concept to clinic. J Am Ceram Soc. 1991;74:1487–510.

Bolelli G, Cannillo V, Gadow R, Killinger A, Lusvarghi L, Rauch J, Romagnoli M. Effect of the suspension composition on the microstructural properties of high velocity suspension flame sprayed (HVSFS) Al2O3 coatings. Surf Coat Technol. 2010;204:1163–79.

Oliver WC, Pharr GM. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res. 1992;7:1564–83.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterial. 2006;27:2907–15.

Giordano C, Sandrini E, Busini V, Chiesa R, Fumagalli G, Giavaresi G, Fini M, Giardino R, Cigada A. A new chemical etching process to improve endosseous implant osseointegration: In vitro evaluation on human osteoblast-like cells. Int J Artif Organs. 2006;29:772–80.

De Nardo L, Raffaini G, Ganazzoli F, Chiesa R. Surface modification of biomaterials: methods, analysis and applications. In: Williams R, editor. Metal surface oxidation and surface interactions. Cambridge: Woodhead; 2011. p. 102–42.

De Nardo L, Moscatelli M, Silvi F, Tanzi MC, Yahia LH, Farè, S. Chemico-physical modifications induced by plasma and ozone sterilizations on shape memory polyurethane foams. J Mater Sci Mater Med. 2010;21:2067–78.

Bolelli G, Cannillo V, Lusvarghi L, Manfredini T, Siligardi C, Bartuli C, Loreto A, Valente T. Plasma-sprayed glass-ceramic coatings on ceramic tiles: microstructure, chemical resistance and mechanical properties. J Eur Ceram Soc. 2005;25:1835–53.

Gout R, Oelkers EH, Schoit J, Zwick A. The surface chemistry and structure of acid-leached albite: New insights on the dissolution mechanism of the alkali feldspars. Geochim Cosmochim Acta. 1997;61:3013–8.

Gao X, Wachs IE. Structural characteristics and reactivity properties of highly dispersed Al2O3/SiO2 and V2O5/Al2O3/SiO2 catalysts. J Catal. 2000;192:18–28.

Galeener FL, Mikkelsen JC Jr. Raman studies of the thermal oxide of silicon. Solid State Commun. 1981;37:719–23.

Xie S, Iglesia E, Bell AT. Effects of hydration and dehydration on the structure of silica-supported vanadia species. Langmuir. 2000;16:7162–7.

Murray CA, Gretyak TJ. Intrinsic surface phonons in amorphous silica. Phys Rev B Condens Matter Mater Phys. 1979;20:3368–87.

Delbos C, Fazilleau J, Rat V, Coudert JF, Fauchais P, Pateyron B. Phenomena involved in suspension plasma spraying. Part 2: zirconia particle treatment and coating formation. Plasma Chem Plasma Process. 2006;26:393–414.

Kaβner H, Vaβen R, Stöver D. Study on instant droplet and particle stages during suspension plasma spraying (SPS). Surf Coat Technol. 2008;202:4355–61.

Fauchais P, Rat V, Coudert J-F, Etchart-Salas R, Montavon G. Operating parameters for suspension and solution plasma-spray coatings. Surf Coat Technol. 2008;202:4309–17.

Oberste Berghaus J, Legoux J-G, Moreau C, Tarasi F, Chráska T. Mechanical and thermal transport properties of suspension thermal-sprayed alumina-zirconia composite coatings. J Therm Spray Technol. 2008;17:91–104.

Pawlowski L. Suspension and solution thermal spray coatings. Surf Coat Technol. 2009;203:2807–29.

Lefebvre L, Gremillard L, Chevalier J, Zenati R, Bernache-Assolant D. Sintering behaviour of 45S5 bioactive glass. Acta Biomater. 2008;4:1894–903.

Lefebvre L, Chevalier J, Gremillard L, Zenati R, Thollet G, Bernache-Assolant D, Govin A. Structural transformations of bioactive glass 45S5 with thermal treatments. Acta Mater. 2007;55:3305–13.

Lin C-C, Huang L-C, Shen P. Na2CaSi2O6–P2O5 based bioactive glasses. Part 1: elasticity and structure. J Non-Cryst Solids. 2005;351:3195–203.

Dongmo E, Wenzelburger M, Gadow R. Analysis and optimization of the HVOF process by combined experimental and numerical approaches. Surf Coat Technol. 2008;202:4470–8.

Poirier T, Planche MP, Landemarre O, Coddet C. Particles spreading phenomena in the case of glass thermal spraying. J Therm Spray Technol. 2008;17:564–73.

Jiang X, Wan Y, Herman H, Sampath S. Role of condensates and adsorbates on substrate surface on fragmentation of impinging molten droplets during thermal spray. Thin Solid Films. 2001;385:132–41.

Chandra S, Fauchais P. Formation of solid splats during thermal spray deposition. J Therm Spray Technol. 2009;18:148–80.

Bolelli G, Rauch J, Cannillo V, Killinger A, Lusvarghi L, Gadow R. Microstructural and tribological investigation of high-velocity suspension Flame sprayed (HVSFS) Al2O3 coatings. J Therm Spray Technol. 2009;18:35–49.

Srivatsan VR, Dolatabadi A. Simulation of particle-shock interaction in a high velocity oxygen fuel process. J Therm Spray Technol. 2006;15:481–7.

Arcondéguy A, Grimaud A, Denoirjean A, Gasgnier G, Huguet C, Pateyron B, Montavon G. Flame-sprayed glaze coatings: effects of operating parameters and feedstock characteristics onto coating structures. J Therm Spray Technol. 2007;16:978–90.

Gross KA, Saber-Samandari S, Heemann KS. Evaluation of commercial implants with nanoindentation defines future development needs for hydroxyapatite coatings. J Biomed Mater Res B. 2010;93:1–8.

Cao N, Dong J, Wang Q, Ma Q, Xue C, Li M. An experimental bone defect healing with hydroxyapatite coating plasma sprayed on carbon/carbon composite implants. Surf Coat Technol. 2010;205:1150–6.

Valerio P, Pereira MM, Goes AM, Leite MF. The effect of ionic products from bioactive glass dissolution on osteoblast proliferation and collagen production. Biomaterial. 2004;25:2941–8.

Vitale Brovarone C, Verné E, Appendino P. Macroporous bioactive glass-ceramic scaffolds for tissue engineering. J Mater Sci Mater Med. 2006;17:1069–78.

Cuscó R, Guitián F, de Aza S, Artús L. Differentiation between hydroxyapatite and β-tricalcium phosphate by means of μ-Raman spectroscopy. J Eur Ceram Soc. 1998;18:1301–5.

Khavryuchenko VD, Khavryuchenko OV, Lisnyak VV. Quantum chemical and spectroscopic analysis of calcium hydroxyapatite and related materials. J Solid State Chem. 2007;180:702–12.

Agathopoulos S, Tulyaganov DU, Ventura JMG, Kannan S, Karakassides MA, Ferreira JMF. Formation of hydroxyapatite onto glasses of the CaO–MgO–SiO2 system with B2O3, Na2O, CaF2 and P2O5 additives. Biomaterial. 2006;27:1832–40.

Antonakos A, Liarokapis E, Leventouri T. Micro-Raman and FTIR studies of synthetic and natural apatites. Biomaterial. 2007;28:3043–54.

Cerruti M, Bianchi CL, Bonino F, Damin A, Perardi A, Morterra C. Surface modifications of bioglass immersed in TRIS-buffered solution. A multitechnical spectroscopic study. J Phys Chem B. 2005;109:14496–505.

Peitl O, Zanotto ED, Hench LL. Highly bioactive P2O5–Na2O–CaO–SiO2 glass-ceramics. J Non-Cryst Solids. 2001;292:115–26.

Price N, Bendall SP, Frondoza C, Jinnah RH, Hungerford DS. Human osteoblast-like cells (MG63) proliferate on a bioactive glass surface. J Biomed Mater Res. 1997;37:394–400.

Au AY, Au RY, Demko JL, McLaughlin RM, Eves BE, Frondoza CG. Consil® bioactive glass particles enhance osteoblast proliferation and selectively modulate cell signaling pathways in vitro. J Biomed Mater Res. 2010;94A:380–8.

Carinci F, Palmieri A, Martinelli M, Perrotti V, Piattelli A, Brunelli G, Arlotti M, Pezzetti F. Genetic portrait of osteoblast-like cells cultured on perioglas. J Oral Implant. 2007;33:327–33.

Anselme K, Sharrock P, Hardouin P, Dard M. In vitro growth of human adult bone-derived cells on hydroxyapatite plasma-sprayed coatings. J Biomed Mater Res. 1997;34:247–59.

Yang F, Xie Y, Li H, Tang T, Zhang X, Gan Y, Zheng X, Dai K. Human bone marrow-derived stromal cells cultured with a plasma sprayed CaO–ZrO2–SiO2 coating. J Biomed Mater Res B. 2010;95:192–201.

Gomes PS, Botelho C, Lopes MA, Santos JD, Fernandes MH. Evaluation of human osteoblastic cell response to plasma-sprayed silicon-substituted hydroxyapatite coatings over titanium substrates. J Biomed Mater Res. 2010;94:337–46.

Bhadang KA, Holding CA, Thissen H, McLean KM, Forsythe JS, Haynes DR. Biological responses of human osteoblasts and osteoclasts to flame-sprayed coatings of hydroxyapatite and fluorapatite blends. Acta Biomater. 2010;6:1575–83.

Heimann RB. Design of novel plasma sprayed hydroxyapatite-bond coat bioceramic systems. J Therm Spray Technol. 1999;8:597–604.

Acknowledgements

L. Altomare and L. De Nardo thank Dr. Monica Moscatelli and Prof. Silvia Farè for technical support in cell culture tests and acknowledge MIUR for FIRB grant “SAST”. L. De Nardo thanks Politecnico di Milano (Grant: 5 per Mille Junior) and the Italian Institute of Technology (IIT) for economic support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Altomare, L., Bellucci, D., Bolelli, G. et al. Microstructure and in vitro behaviour of 45S5 bioglass coatings deposited by high velocity suspension flame spraying (HVSFS). J Mater Sci: Mater Med 22, 1303–1319 (2011). https://doi.org/10.1007/s10856-011-4307-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4307-6