Abstract

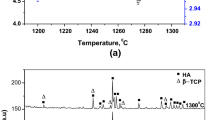

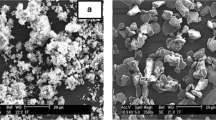

Microwave sintering is traditionally employed to reduce the sintering temperature required to densify powder compacts. The effect of microwave heating on hydroxyapatite (HA)–zirconia (ZrO2) green bodies has been investigated in order to understand how microwave energy may affect the physical and mechanical properties of the resultant densified composites. Laboratory synthesised nano-sized HA and a commercial nano-sized ZrO2 powder have been ball milled to create mixtures containing 0–5 wt% ZrO2 loadings. Compacts were microwave sintered at either 700, 1000 or 1200°C with a 1 h hold time. Comparative firings were also performed in a resistive element furnace using the same heating profile in order to assess the differences between conventional and microwave heating on the physical, mechanical and microstructural properties of the composites. Samples sintered at 700°C show little sign of densification with open porosities of approximately 50%. Composites conventionally sintered at 1000°C were between 65 and 75% dense, whereas the samples microwave sintered at this temperature were between 55 and 65% dense. Samples sintered at 1200°C showed the greatest degree of densification (>80%) with a corresponding reduction in open porosities. TCP generation occurred as a consequence of sintering at 1200°C, even with 0 wt% ZrO2, and increased degradation of the HA phase to form significant amounts of TCP occurred with increasing additions of ZrO2, along with increasing open porosity. Nanosized ZrO2 prevents the densification of the HA matrix by effectively pinning grain boundaries and this effect is more pronounced in the MS materials. Similar strengths are achieved between the microwave and conventionally sintered samples. Greater amount of open porosity and pore interconnectivity are seen in the MS samples, which are considered to be useful for biomedical applications as they can promote osteo-integration.

Similar content being viewed by others

References

Kalita SJ, Bhardwaj A, Bhatt HA. Nanocrystalline calcium phosphate ceramics in biomedical engineering. Mater Sci Eng C. 2006;27(3):441–9.

Prabakaran K, Kannan S, Rajeswari S. Development and characterisation of zirconia and hydroxyapatite composites for orthopaedic applications. Trends Biomater Artif Organs. 2005;18(2):114–6.

Manley MT, Sutton K, Dumbleton J. Calcium phosphates: a survey of the orthopaedic literature. In: Epinette JA, Manley MT, editors. Fifteen years of clinical experience with hydroxyapatite coatings in joint arthroplasty. New York: Springer-Verlag; 2004. p. 452.

Itoh S, Kikuchi M, Takakuda K, Koyama Y, Matsumoto HN, Ichinose S, et al. The biocompatibility and osteoconductive activity of a novel hydroxyapatite/collagen composite biomaterial, and its function as a carrier of rhBMP-2. J Biomed Mater Res. 2000;54(3):445–53.

Anselme K, Noel B, Flautre B, Blary MC, Delecourt C, Descamps M, et al. Association of porous hydroxyapatite and bone marrow cells for bone regeneration. Bone. 1999;25(2):51S–4S.

Erbe EM, Marx JG, Clineff TD, Bellincampi LD. Potential of an ultraporous β-tricalcium phosphate synthetic cancellous bone void filler and bone marrow aspirate composite graft. Eur Spine J. 2001;10(2):S141–6.

Heimann RB, Vu TA. Effects of CaO on thermal decomposition during sintering of composite hydroxyapatite–zirconia mixtures for monolithic bioceramic implants. J Mater Sci Lett. 1997;16(6):437–9.

White AA, Best SM, Kinloch IA. Hydroxyapatite-carbon nanotube composites for biomedical applications: a review. Int J Appl Ceram Technol. 2007;4(1):1–13.

Bernache-Assollant D, Ababou A, Champion E, Heughebaert M. Sintering of calcium phosphate hydroxyapatite Ca10(PO4)6(OH)2. I Calcination and grain growth. J Eur Ceram Soc. 2003;23(2):229–41.

Hing KA, Gibson IR, Di Silvio L, Best SM, Bonfield W. Effect of variation in Ca:P ratio on the cellular response of primary human osteoblast-like cells to hydroxyapatite-based ceramics. Bioceramics. 1998;11:293–6.

Nagarajan VS, Rao KJ. Structural, mechanical and biocompatibility studies of hydroxyapatite-derived composites toughened by zirconia addition. J Mater Chem. 1993;3(1):43–51.

Brosnan KH. Sintering of alumina parts with microwave energy. USA: The Pennsylvania State University; 2002. p. 67.

Ciacchi FT, Nightingale SA, Badwal SPS. Microwave sintering of zirconia–yttria electrolytes and measurements of their ionic conductivity. Solid State Ion. 1996;86–88(2):1167–72.

Masonis JL, Bourne RB, Ries MD, McCalden RW, Salehi A, Kelman DC. Zirconia femoral head fractures: a clinical and retrieval analysis. J Arthroplast. 2004;19(7):898–905.

DeAza AH, Chevalier J, Fantozzi G, Schehl M, Torrecillas R. Crack growth resistance of alumina, zirconia and zirconia toughened alumina ceramics for joint prostheses. Biomaterials. 2001;23:937–45.

Kong Y, Yang Z, Zhang G, Yuan Q. Friction and wear characteristics of mullite. ZTM and TZP ceramics. Wear. 1998;218(2):159–66.

Casellas D, Nagl MM, Llanes L, Anglada M. Fracture toughness of alumina and ZTA ceramics: microstructural coarsening effects. J Mater Process Technol. 2003;143–144:148–52.

Towler MR, Gibson IR. The effect of low levels of zirconia addition on the mechanical properties of hydroxyapatite. J Mater Sci Lett. 2001;20(18):1719–22.

Evis Z. Reactions in hydroxylapatite-zirconia composites. Ceram Int. 2006;33(6):987–91.

Ruys AJ, Wei M, Sorrell CC, Dickson MR, Brandwood A, Milthorpe BK. Sintering effects on the strength of hydroxyapatite. Biomaterials. 1995;16(5):409–15.

Upadhyaya DD, Ghosh A, Gurumurthy KR, Prasad R. Microwave sintering of cubic zirconia. Ceram Int. 2001;27(4):415–8.

Goldstein A, Travitzky N, Singurindy A, Kravchik M. Direct microwave sintering of yttria-stabilized zirconia at 245 GHz. J Eur Ceram Soc. 1999;19(12):2067–72.

Ramesh PD, Brandon D, Schachter L. Use of partially oxidized SiC particle bed for microwave sintering of low loss ceramics. Mater Sci Eng. 1999;266(1–2):211–20.

Vaidhyanathan B, Binner JGP. Densification of nanostructured YSZ green compacts. Key Eng Mater. 2004;246–248:2339–42.

Thostenson ET, Chou TW. Microwave processing: fundamentals and applications. Composites A. 1999;30(9):1055–71.

Clark DE, Folz DC, West JK. Processing materials with microwave energy. Mater Sci Eng A. 2000;287(2):153–8.

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials. 2005;26(7):5474–91.

Klenke FM, Liu Y, Yuan H, Hunziker EB, Siebenrock KA. Impact of pore size on the vascularization and osseointegration of ceramic bone substitutes in vivo. J Biomed Mater Res A. 2008;85(3):777–86.

Chang BS, Lee CK, Hong KS, Youn HJ, Ryu HS, Chung SS, et al. Osteoconduction at porous hydroxyapatite with various pore configurations. Biomaterials. 2000;21(12):1291–8.

Kuboki Y, Takita H, Kobayashi D, Tsuruga E, Inoue M, Murata M, et al. BMP-induced osteogenesis on the surface of hydroxyapatite with geometrically feasible and nonfeasible structures: topology of osteogenesis. J Biomed Mater Res A. 1998;39(2):190–9.

Jarcho M, Bolen CH, Thomas MB, Bobick J, Kay JF, Doremus RH. Hydroxylapatite synthesis and characterisation in dense polycrystalline form. J Mater Sci. 1976;11(11):2027–35.

Ingel RP, Lewis D III. Lattice parameters and density for Y2O3-stabilized ZrO2. J Am Ceram Soc. 1986;69(4):325–32.

CEN. Dental ceramic (ISO 6872-1995). In: Standardization ECf, editor; 1998.

Evis Z, Usta M, Kutbay I. Hydroxyapatite and zirconia composites: effect of MgO and MgF2 on the stability of phases and sinterability. Mater Chem Phys. 2008;110(1):68–75.

Gross KA, Berndt CC. Thermal processing of hydroxyapatite for coating production. J Biomed Mater Res. 1998;39(4):580–7.

Pontier C, Viana M, Champion E, Chulia D. Apatitic calcium phosphates used in compression: rationalisation of the end-use properties. Powder Technol. 2002;130:436–41.

Elliot JC. Structure and chemistry of the apatites and other calcium orthophosphates. Amsterdam: Elsevier; 1994.

Evis Z, Ergun C, Doremus RH. Hydroxylapatite–zirconia composites: thermal stability of phases and sinterability as related to the CaO–ZrO2 phase diagram. J Mater Sci. 2005;40(5):1127–34.

Buys AJ, Sorrell CC, Brandwood A, Milthorpe BK. Hydroxyapatite sintering characteristics: correlation with powder morphology bv high-resolution microscopy. J Mater Sci Lett. 1995;14(10):744–7.

Acknowledgement

This work was funded by Enterprise Ireland Technology Development Grant EI/TD/2006/0328.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Curran, D.J., Fleming, T.J., Towler, M.R. et al. Mechanical properties of hydroxyapatite–zirconia compacts sintered by two different sintering methods. J Mater Sci: Mater Med 21, 1109–1120 (2010). https://doi.org/10.1007/s10856-009-3974-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-009-3974-z