Abstract

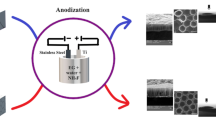

Surface-porous titanium samples were prepared by anodic oxidation in H2SO4, H3PO4 and CH3COOH electrolytes under various electrochemical conditions. X-ray diffraction (XRD), scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDX) were employed to characterize the structure, morphology and chemical composition of the surface layer, respectively. Closer analysis on the effect of the electrochemical conditions on pore configuration was involved. It can be indicated that porous titania was formed on the surface layer, and the pore configuration was influenced by electrolyte composition and crystal structure of the titania. The fibroblast cells experiment showed that anodic oxidation of titanium surface could promote fibroblast adhesion on Ti substrate. The results suggested that anodic oxidation of Ti in CH3COOH was suitable to obtain surface-porous titanium oxides layers, which might be beneficial for better soft tissue ingrowths.

Similar content being viewed by others

References

Van Noort R. Titanium: the implant material of today. J Mater Sci. 1987;22:3801–11.

Wang K. The use of titanium for medical applications in the USA. Mater Sci Eng. 1996;213 A:134–7.

Brash JL. Biomaterials in Canada: the first four decades. Biomaterials. 2005;26:7209–20.

Puleo DA, Kissling RA, Sheu MS. A technique to immobilize bioactive proteins, including bone morphogenetic protein-4 (BMP-4), on titanium alloy. Biomaterials. 2002;23:2079–87.

Caulier H, Vercaigne S, Naert I, Waerden JVD, Wolke J, Kalke W, et al. The effect of Ca-P plasma-sprayed coatings on the initial bone healing of oral implants: an experimental study in the goat. J Biomed Mater Res. 1997;34:121–8.

Kim HM, Miyaji F, Kokubo T, Nishuguchi S, Nakamura T. Grade surface structure of bioactive titanium prepared by chemical treatment. J Biomed Mater Res. 1999;45:100–7.

Kim HM, Miyaji F, Kokubo T, Nakamura T. Effect of heat treatment on apatite-forming ability of Ti metal induced by alkali treatment. J Mater Sci: Mater Med. 1997;8:341–7.

Kim HM, Kokubo T, Miyaji F, Nakamura T. Preparation of bioactive Ti and its alloys via simple chemical surface treatment. J Biomed Mater Res. 1996;32:409–17.

Liang B, Fujibayashi S, Neo M, Tamura J, Kim HM, Uchida M, et al. Histological and mechanical investigation of the bone-bonding ability of anodically oxidized titanium in rabbits. Biomaterials. 2003;24:4959–66.

Yang BC, Uchida M, Kim HM, Zhang XD, Kokubo T. Preparation of bioactive titanium metal via anodic oxidation treatment. Biomaterials. 2004;25:1003–10.

Cui X, Kim HM, Kawashit M, Wang L, Xiong T, Kokubo T, et al. Preparation of bioactive titania films on titanium metal via anodic oxidation. Dent Mater. 2009;25:80–6.

Oh HJ, Lee JH, Kim YJ, Suh SJ, Lee JH, Chi CS. Surface characteristics of porous anodic TiO2 layer for biomedical applications. Mater Chem Phys. 2008;109:10–4.

Pilliar RM. Powder metal-made orthopedic implants with porous surface for fixation by tissue ingrowth. Clin Orthop. 1983;176:42–51.

Gottsauner-Wolf F, Egger EL, Schultz FM, Sim FH, Chao EY. Tendons attached to prostheses by tendon-bone block fixation: an experimental study in dogs. J Orthop Res. 1994;12:814–21.

LaBerge M, Bobyn JD, Rivard CH, Drouin G, Duval P. Study of soft tissue ingrowth into canine porous coated femoral implants designed for osteosarcomas management. J Biomed Mater Res. 1990;24:959–71.

Bobyn JD, Hacking SA, Tanzer M, Krygier JJ. Tissue response to porous coated acetabular cups: a canine model. J Arthrop. 1999;14:347–54.

Kon M, Hirakata LM, Asaoka K. Porous Ti-6Al-4 V alloy fabricated by spark plasma sintering for biomimetic surface modification. J Biomed Mater Res. 2004;68B:88–93.

Thelen S, Barthelat F, Brinson LC. Mechanics considerations for microporous titanium as an orthopedic implant material. J Biomed Mater Res. 2004;69A:601–10.

Assad M, Jarzem P, Leroux MA, Coillard C, Chernyshov AV, Charette S, et al. Porous titanium–nickel for intervertebral fusion in a sheep model: part 1. Histomorphometric and radiological analysis. J Biomed Mater Res. 2003;64B:107–20.

Assad M, Chernyshov AV, Jarzem P, Leroux MA, Coillard C, Charette S, et al. Porous titanium–nickel for intervertebral fusion in a sheep model: part 2. Surface analysis and nickel release assessment. J Biomed Mater Res. 2003;64B:121–9.

Wen CE, Yamada Y, Shimojima K, Chino Y, Asahina T, Mabuchi M. Processing and mechanical properties of autogenous titanium implant materials. J Mater Sci: Mater Med. 2002;13:397–401.

Zardiackas LD, Parsell DE, Dillon LD, Mitchell DW, Nunnery LA, Poggie R. Structure, metallurgy, and mechanical properties of a porous tantalum foam. J Biomed Mater Res. 2001;58:180–7.

Garrett R, Abhay P, Dimitrios PA. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials. 2006;27:2651–70.

Fujibayashi S, Neo M, Kim HM, Kokubo T, Nakamura T. Osteoinduction of porous bioactive titanium metal. Biomaterials. 2004;25:443–50.

Park IS, Lee MH, Bae TS, Seol KW. Effects of anodic oxidation parameters on a modified titanium surface. J Biomed Mater Res Part B: Appl Biomater. 2008;84B:422–9.

Sul YT, Johansson CB, Jeong YS, Albrektsson T. The electrochemical oxide growth behaviour on titanium in acid and alkaline electrolytes. Med Eng Phys. 2001;23:329–46.

Kuromoto NK, Simão RA, Soares GA. Titanium oxide films produced on commercially pure titanium by anodic oxidation with different voltages. Mater Charact. 2007;58:114–21.

Zwilling V, Aucouturier M, Ceretti ED. Anodic oxidation of titanium and TA6 V alloy in chromic media. An electrochemical approach. Electrochim Acta. 1999;45:921–9.

Sul YT, Johansson CB, Petronis S, Krozer A, Jeong YS, Wennerberg A, et al. Characteristics of the surface oxides on turned and electrochemically oxidized pure titanium implants up to dielectric breakdown: the oxide thickness, micropore configurations, surface roughness, crystal structure and chemical composition. Biomaterials. 2002;23:491–501.

Lin CS, Chen MT, Liu JH. Structural evolution and adhesion of titanium oxide film containing phosphorus and calcium on titanium by anodic oxidation. J Biomed Mater Res. 2008;85A:378–87.

Oliveira MV, Pereira LC, Cairo CAA. Porous structure characterization in titanium coating for surgical implants. Mater Res. 2002;5:269–73.

Sul YT, Johansson CB, Jeong YS, Albrektsson T. The electrochemical oxide growth behaviour on titanium in acid and alkaline electrolytes. Med Eng Phys. 2001;23:329–46.

Wu HH, Lu XY, Long BH, Wang XQ, Wang JB, Jin ZS. The effects of cathodic and anodic voltages on the characteristics of porous nanocrystalline titania coatings fabricated by microarc oxidation. Mater Lett. 2005;59:370–5.

Dervos CT, Thirios Ef, Novacovich J, Vassiliou P, Skafidas P. Permittivity properties of thermally treated TiO2. Mater Lett. 2004;58:1502–7.

Christenson EM, Anseth KS. Nanobiomaterial applications in orthopedics. J Orthop Res. 2007;25:11–22.

Zhang F, Shi ZL, Chua PH, Kang ET, Neoh KG. Functionalization of titanium surfaces via controlled living radical polymerization: from antibacterial surface to surface for osteoblast adhesion. Ind Eng Chem Res. 2007;46:9077–86.

Ou KL, Shih YH, Huang CF, Chen CC, Liu CM. Preparation of bioactive amorphous-like titanium oxide layer on titanium by plasma oxidation treatment. Appl Surf Sci. 2008;255:2046–51.

Acknowledgment

This work has been supported by the National Natural Science Foundation of China (project no. 60871062 and 50873066). The supports of Sichuan Province through a Science Fund for Distinguished Young Scholars of Sichuan Province (08ZQ026-007) and Key Technologies Research and Development Program of Sichuan Province (2008SZ0021 and 2006Z08-001-1) are also acknowledged with gratitude. This work was also supported by the Specialized Research Fund for the Doctoral Program of Higher Education from Ministry of Education of China (No. 20070610131). We thank Analytical & Testing Center, Sichuan University for the assistance with the microscopy work. The authors would also like to thank Mrs. Hui Wang of Analytical & Testing Center, Sichuan University for her support and encouragement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, L., Yin, G., Yan, D. et al. Structure, morphology and fibroblasts adhesion of surface-porous titanium via anodic oxidation. J Mater Sci: Mater Med 21, 259–266 (2010). https://doi.org/10.1007/s10856-009-3832-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-009-3832-z