Abstract

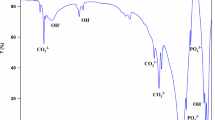

In situ hydroxyapatite/apatite–wollastonite glass ceramic composite was fabricated by a three dimensional printing (3DP) technique and characterized. It was found that the as-fabricated mean green strength of the composite was 1.27 MPa which was sufficient for general handling. After varying sintering temperatures (1050–1300°C) and times (1–10 h), it was found that sintering at 1300°C for 3 h gave the greatest flexural modulus and strength, 34.10 GPa and 76.82 MPa respectively. This was associated with a decrease in porosity and increase in densification ability of the composite resulting from liquid phase sintering. Bioactivity tested by soaking in simulated body fluid (SBF) and In Vitro toxicity studies showed that 3DP hydroxyapatite/A–W glass ceramic composite was non-toxic and bioactive. A new calcium phosphate layer was observed on the surface of the composite after soaking in SBF for only 1 day while osteoblast cells were able to attach and attain normal morphology on the surface of the composite.

Similar content being viewed by others

References

J.L. Simon, T.D. Roy, J.R. Parsons, E.D. Rekow, V.P. Thompson, J. Kemnitzer, J.L. Ricci, J. Biomed. Mater. Res. 66A, 275 (2003). doi:10.1002/jbm.a.10569

T.D. Roy, J.L. Simon, J.L. Ricci, E.D. Rekow, V.P. Thompson, J.R. Parsons, J. Biomed. Mater. Res. 67A, 1228 (2003). doi:10.1002/jbm.a.20034

H. Seitz, W. Rieder, S. Irsen, B. Leukers, C. Tille, J. Biomed. Mater. Res. Part B Appl. Biomater. 74B, 782 (2005). doi:10.1002/jbm.b.30291

R. Chumnanklang, T. Panyathammaporn, K. Sitthiseripratip, J. Suwanprateeb, Mater. Sci. Eng. C 27, 914 (2007). doi:10.1016/j.msec.2006.11.004

J. Will, R. Melcher, C. Treul, N. Travitzky, U. Kneser, E. Polykandriotis, R. Horch, P. Greil, J. Mater. Sci. Mater. Med. 19, 2781 (2008). doi:10.1007/s10856-007-3346-5

K.F. Leong, C.M. Cheah, C.K. Chua, Biomaterials 24(13), 2363 (2003). doi:10.1016/S0142-9612(03)00030-9

T. Boland, A. Ovsianikov, B.N. Chickov, A. Doraiswamy, R.J. Narayan, W.Y. Yeong, K.F. Leong, C.K. Chua, Adv. Mater. Process 165(4), 51–53 (2007)

B.D. Kernan, E.M. Sachs, S.M. Allen, A. Lorenz, C. Sachs, L. Raffenbeul, A. Pettavino, J. Metallur. Mater. Transac. A 36(10), 2815 (2005). doi:10.1007/s11661-005-0278-x

J. Suwanprateeb, Polym. Int. 55(1), 57 (2006). doi:10.1002/pi.1918

J. Suwanprateeb, J. Mater. Sci. Mater. Med. 17(12), 1383 (2006). doi:10.1007/s10856-006-0614-8

J. Suwanprateeb, Rapid Prototyping J. 13(1), 48 (2007). doi:10.1108/13552540710719217

J. Suwanprateeb, R. Sanngam, W. Suwanpreuk, J. Mater. Sci. Mater. Med. 19(7), 2637 (2008). doi:10.1007/s10856-007-3362-5

S. Padilla, J. Roman, S. Sanchez-Salcedo, M. Vallet-Regi, Acta Biomater. 2, 331 (2006). doi:10.1016/j.actbio.2006.01.006

Y.E. Greish, P.W. Brown, J. Biomed. Mater. Res. 52, 687 (2000). doi:10.1002/1097-4636(20001215)52:4<687::AID-JBM13>3.0.CO;2-K

D.C. Tancred, A.J. Carr, B.A.O. McCormack, J. Mater. Sci. Mater. Med. 12, 81 (2001). doi:10.1023/A:1026773522934

G. Georgiou, J.C. Knowles, Biomaterials 22, 2811 (2001). doi:10.1016/S0142-9612(01)00025-4

G. Goller, H. Demirkiran, F.N. Oktar, E. Demirkesen, Ceram. Int. 29, 721 (2003). doi:10.1016/S0272-8842(02)00223-7

S.J. Kalita, S. Bose, H.L. Hosick, A. Bandyopadhyay, Biomaterials 25, 2331 (2004). doi:10.1016/j.biomaterials.2003.09.012

T. Kokubo, S. Ito, M. Shigematsu, S. Sakka, J. Mater. Sci. 20, 2001 (1985). doi:10.1007/BF01112282

T. Kokubo, H.M. Kim, M. Kawashita, Biomaterials 24, 2161 (2003). doi:10.1016/S0142-9612(03)00044-9

T. Kokubo, H. Takadama, Biomaterials 27, 2907 (2006). doi:10.1016/j.biomaterials.2006.01.017

R.M. Shelton, A.C. Rasmussen, J.E. Davies, Biomaterials 9, 22 (1988). doi:10.1016/0142-9612(88)90065-8

J.F. Bredt, T.C. Anderson, D.B. Russel, Three Dimensional Printing Material System and Method. US Patent Application No US 2004/0138336 A1

S. Ramesh, C.Y. Tan, I. Sopyan, M. Hamdi, W.D. Teng, Sci. Technol. Adv. Mater. 8, 124 (2007). doi:10.1016/j.stam.2006.11.002

A.S. Kosmos, L.I. Bellic, D. Susnik, FIZIKA 2, 85 (1996)

W.D. Kingery, J. Appl. Phys. 30, 301 (1959). doi:10.1063/1.1735155

I. Oh, N. Nomura, N. Masahashi, S. Hanada, Scr. Mater. 49(12), 1197 (2003). doi:10.1016/j.scriptamat.2003.08.018

M. Milosevski, J. Bossert, D. Milosevski, N. Gruevska, Ceram. Int. 25(8), 693 (1999). doi:10.1016/S0272-8842(99)00003-6

H. Oonishi, L.L. Hench, J. Wilson, F. Sugihara, E. Tsuji, M. Matsuura, S. Kin, T. Yamamoto, S. Mizokawa, J. Biomed. Mater. Res. 51(1), 37 (2000). doi:10.1002/(SICI)1097-4636(200007)51:1<37::AID-JBM6>3.0.CO;2-T

H. Teramoto, A. Kawai, S. Sugihara, A. Yoshida, H. Inoue, Key. Eng. Mater. 240/242, 269 (2003)

J. Vandiver, N. Patel, W. Bonfield, C. Ortiz, Key. Eng. Mater. 284, 497 (2005). doi:10.4028/0-87849-961-x.497

Acknowledgement

This work was supported by a grant from National Metal and Materials Technology Center, National Science and Technology Development Agency. The authors would like to extend their gratitude to P. Tesavibul for helping in SBF soaking experiment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suwanprateeb, J., Sanngam, R., Suvannapruk, W. et al. Mechanical and in vitro performance of apatite–wollastonite glass ceramic reinforced hydroxyapatite composite fabricated by 3D-printing. J Mater Sci: Mater Med 20, 1281–1289 (2009). https://doi.org/10.1007/s10856-009-3697-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-009-3697-1