Abstract

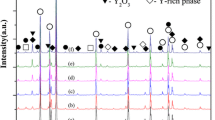

With the rapid development of electronic components toward miniaturization and integration, ZnO-based varistor ceramics sintered at a low temperature below 961 °C have received extensive attention. This work systematically explored the effect of sintering temperature on the microstructure and electrical properties of 98 mol%ZnO + 0.5 mol%V2O5 + 0.5 mol%TiO2 + 0.5 mol%Co2O3 + 0.5 mol%MnO (short for ZVTCM) ceramics prepared via a conventional solid-state method. The X-ray diffraction results revealed that all the ZVTCM ceramics consist of major ZnO grains, and minor secondary phases, including Zn3(VO4)2 and Mn2TiO4. Furthermore, the average grain size was found to increase from 2.69 to 11.42 μm until the sintering temperature reaches up to 925 °C. Higher sintering temperature results in an abnormal grain growth behavior and increased content of oxygen vacancies in ZVTCM ceramics, tending to degrade the varistor properties. Excellent varistor properties can be available in the ZVTCM ceramic sintered at 850 °C, involving a nonlinear coefficient (α) of 21.9, a leakage current density (JL) of 59.4 μA/cm2, and a breakdown electric field (E1mA) of 523 V/mm.

Similar content being viewed by others

Data availability

Data available on request from the authors.

References

T.K. Gupta, J. Am. Ceram. Soc. 73, 1817 (1990)

Y.Y. Gong, R.Q. Chu, Z.J. Xu, J. Sun, F.X. Chao, S. Ma, J.G. Hao, H.Y. Li, G.R. Li, Ceram. Int. 41, 9183 (2015)

T.Y. Li, M. Zhao, X. Li, J. Mater. Sci.: Mater. Electron. 29, 2758 (2018)

T. Tian, L.Y. Zheng, M. Podlogar, Z.Y. Man, X.Z. Ruan, X. Shi, S. Bernik, G.R. Li, J. Eur. Ceram. Soc. 42, 2268 (2022)

J.K. Liu, Z.Z. Li, S.H. Liu, R.K. Xu, J.J. Chen, J.F. Su, L. Li, W.B. Cao, J. Mater. Sci.: Mater. Electron. 33, 12104 (2022)

J.Z. Zhao, B.X. Wang, K. Lu, Ceram. Int. 40, 14229 (2014)

F.C. Peng, D.C. Zhu, Ceram. Int. 44, 21034 (2018)

A. Marino-Gamez, M. Miranda-Lopez, M. Hernandez, A. Bondarchuk, L. Falcon-Franco, L. Garica-Ortiz, J. Aguilar-Martinez, J. Alloy Compd. 880, 160529 (2021)

G.Z. Zang, J. Du, R.Q. Chu, Z.J. Xu, J. Mater. Sci.: Mater. Electron. 30, 3865 (2019)

T.G. Wang, G.Q. Shao, W.J. Zhang, X.B. Li, X.H. Yu, Ceram. Int. 36, 1063 (2010)

J.Y. Li, K.N. Wu, R. Jia, L.L. Hou, L. Gao, S.T. Li, Mater. Design 92, 546 (2016)

M. Jiang, Z. Cheng, D. Zhao, L. Zhang, D. Xu, T. Nonferr, Metal. Soc. 32, 1589 (2022)

P.F. Meng, J. Hu, J.L. He, Mater. Lett. 195, 209 (2017)

D.R. Clarke, J. Am. Ceram. Soc. 82, 485 (1999)

C.W. Nahm, Ceram. Int. 38, 6651 (2012)

C.W. Nahm, J. Alloy Compd. 578, 132 (2013)

T.K. Roy, Ceram. Int. 47, 35152 (2021)

S. Roy, D. Das, T.K. Roy, J. Eur. Ceram. Soc. 41, 5184 (2021)

M. Zhao, Y.H. Wang, X. Li, H.H. Song, T.T. Sun, Ceram. Int. 46, 20923 (2020)

S. Roy, T.K. Roy, D. Das, Ceram. Int. 45, 24835 (2019)

F. Kharchouche, J. Mater. Sci.: Mater. Electron. 29, 3891 (2018)

X. Qu, W.J. Sun, M.H. Wang, Y. Chen, H.P. Zhang, J. Mater. Sci.: Mater. Electron. 28, 1909 (2017)

H. Hng, K. Knowles, J. Am. Ceram. Soc. 83, 2455 (2000)

C.W. Nahm, J. Am. Ceram. Soc. 94, 3227 (2011)

C.W. Nahm, J. Mater. Sci.: Mater. Electron. 24, 4839 (2013)

M. Zhao, X. Li, Y. Shi, T.Y. Li, B.W. Li, Ceram. Int. 44, 6912 (2018)

C.T. Kuo, C.S. Chen, I.N. Lin, J. Am. Ceram. Soc. 81, 2942 (1998)

S. Rabaie, A.H. Khafagy, M.T. Dawoud, M.T. Attia, Bull. Mater. Sci. 38, 773 (2015)

C.W. Nahm, J. Mater. Sci.: Mater. Electron. 22, 444 (2011)

C.W. Nahm, J. Rare Earth 32, 29 (2014)

C.W. Nahm, Mat. Sci. Semicon. Proc. 16, 1308 (2013)

M. Zhao, Y.H. Wang, T.T. Sun, H.H. Song, J. Mater. Sci.: Mater. Electron. 31, 8206 (2020)

H. Peng, B.Q. Shang, X. Wang, Z.H. Peng, X.L. Chao, P.F. Liang, Z.P. Yang, Ceram. Int. 44, 5768 (2018)

T.Y. Li, X.W. Jiang, J. Li, A.W. Xie, J. Fu, R.Z. Zuo, A.C.S. Appl, Mater. Interfaces 14, 22263 (2022)

T.Y. Li, W.J. Cao, P.F. Chen, J.S. Wang, C.C. Wang, J. Mat. Sci. 56, 13499 (2021)

D. Huang, Z.F. Liu, Y.X. Li, Y. Liu, J. Alloy Compd. 698, 200 (2017)

C.W. Nahm, Ceram. Int. 41, 5196 (2015)

X.M. Li, J.Z. Song, Y.L. Liu, H.B. Zeng, Curr. Appl. Phys. 14, 521 (2014)

T.Y. Li, F. Hong, K. Yang, B.B. Yue, N. Tamura, H. Wu, Z.X. Cheng, C.C. Wang, Sci. Bull. 65, 631 (2020)

T.Y. Li, R.J. Si, J. Wang, S.T. Wang, J. Sun, C.C. Wang, J. Am. Ceram. Soc. 102, 6688 (2019)

A. Biswas, U. Kar, N.R. Jana, Phys. Chem. Chem. Phys. 24, 13965 (2022)

T.Y. Li, R.J. Si, J. Sun, S.T. Wang, J. Wang, R. Ahmed, G.B. Zhu, C.C. Wang, Sensor. Actuat. B-Chem. 293, 151–158 (2019)

W.M. Zhong, X.G. Tang, Q.X. Liu, Y.P. Jiang, W.H. Li, J.L. Yue, Physical B 615, 413080 (2021)

M.W. Yao, Q.X. Li, F. Li, Y. Peng, Z. Su, X. Yao, Mater. Chem. Phys. 206, 48 (2018)

S.J. Chu, M. Zhang, H.L. Deng, Z.H. Wang, Y. Wang, Y.H. Pan, H. Yan, J. Alloy Compd. 689, 475 (2016)

N.N. Luo, K. Han, L.J. Liu, B.L. Peng, X.P. Wang, C.Z. Hu, H.F. Zhou, Q. Feng, X.Y. Chen, Y.Z. Wei, J. Am. Ceram. Soc. 102, 4640 (2019)

S.S. Wu, W.F. Zhu, L.J. Liu, D.P. Shi, S.Y. Zheng, Y.M. Huang, L. Fang, J. Electron Mater. 43, 1055 (2014)

X.J. Sun, J.M. Deng, L.J. Liu, S.S. Liu, D.P. Shi, L. Fang, B. Elouadi, Mater. Res. Bull. 73, 437 (2016)

S. Pandey, D. Kumar, O. Parkash, Ceram. Int. 42, 9686 (2016)

Acknowledgements

The authors acknowledge financial support from the National Natural Science Foundation of China (Grant No. 52072103 and U19A2087), the AHPU innovation team project (S022021058), the Scientific Research Starting Foundation of Anhui Polytechnic University (Grant No. 2021YQQ031), and the Natural Science Foundation of Anhui Polytechnic University (Grant No. Xjky2022029).

Funding

The National Natural Science Foundation of China, No. 52072103, Ruzhong Zuo, U19A2087, Ruzhong Zuo, the AHPU innovation team project, S022021058, Ruzhong Zuo, the Scientific Research Starting Foundation of Anhui Polytechnic University, 2021YQQ031, Tianyu Li, and the Natural Science Foundation of Anhui Polytechnic University, Xjky2022029, Tianyu Li

Author information

Authors and Affiliations

Contributions

TL contributed to investigation, writing of the original draft. WG, AX, and CZ contributed to investigation. DX contributed to editing. RZ contributed to validation, resources, and writing, reviewing, and editing of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflict of financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, T., Guo, W., Xie, A. et al. Structural and electrical properties of ZnO–V2O5–TiO2–Co2O3–MnO varistor ceramics with low sintering temperature. J Mater Sci: Mater Electron 34, 607 (2023). https://doi.org/10.1007/s10854-023-09935-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-09935-1