Abstract

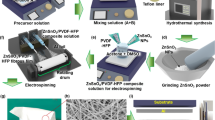

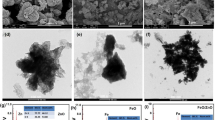

Fibrous piezoelectric structures as an organic structure constitute a new area of advanced materials for flexible and stretchable sensors and actuators. It is highly desirable to design the structure of piezoelectric generator that the external force can be well-distributed across the entire piezoelectric layer to maximize their power generation. This paper presents a multilayer hybrid structure utilizing electrospun nanofibers and three different materials as passive layers (non-piezoelectric layers) to improve the stress/strain distribution across the piezoelectric layer. Results showed that adding a passive layer could increase the bending modulus of the samples and reduce flexibility. However, they still have the required flexibility to be used in a flexible piezoelectric energy harvester. Under the tapping state, the electrical output of polyvinylidene fluoride (PVDF) nanogenerator devices is highly dependent on the passive layer materials. Furthermore, the results under bending showed that electrical output could be increased using any types of passive layers. It was concluded that adding aluminum, cellulose and polyester as passive layers could increase the electrical output about 4.7, 3 and 4.2 times more than the sample without any passive layer, respectively. Finally, the fabricated nanogenerator showed promising potential for applications such as smart textiles and self-powered wearable devices.

Similar content being viewed by others

References

Vivekananthan, V., et al., Triboelectric Nanogenerators: Design, Fabrication, Energy Harvesting, and Portable-Wearable Applications, in Nanogenerators. 2020, IntechOpen.

P. Costa et al., Recent progress on piezoelectric, pyroelectric, and magnetoelectric polymer-based energy-harvesting devices. Energy Technol. 7(7), 1800852 (2019)

K. Polat, Energy harvesting from a thin polymeric film based on PVDF-HFP and PMMA blend. Appl. Phys. A 126, 1–8 (2020)

F. Narita, M. Fox, A review on piezoelectric, magnetostrictive, and magnetoelectric materials and device technologies for energy harvesting applications. Adv. Eng. Mater. 20(5), 1700743 (2018)

M.S. Bafqi, R. Bagherzadeh, M. Latifi, Nanofiber alignment tuning: An engineering design tool in fabricating wearable power harvesting devices. J. Ind. Text. 47(4), 535–550 (2017)

H. Liu et al., A comprehensive review on piezoelectric energy harvesting technology: materials, mechanisms, and applications. Appl. Phys. Rev. 5(4), 041306 (2018)

Bafqi, M.S., et al., Design and fabrication of a piezoelectric out-put evaluation system for sensitivity measurements of fibrous sensors and actuators. J. Ind. Text., 2019: p. 1528083719867443.

Y. Zhang et al., Ferroelectric and piezoelectric effects on the optical process in advanced materials and devices. Adv. Mater. 30(34), 1707007 (2018)

M.S.S. Bafqi, R. Bagherzadeh, M. Latifi, Fabrication of composite PVDF-ZnO nanofiber mats by electrospinning for energy scavenging application with enhanced efficiency. J. Polym. Res. 22(7), 130 (2015)

Y. Zou, L. Bo, Z. Li, Recent progress in human body energy harvesting for smart bioelectronic system. Fundame Res 21, 3806 (2021)

G. Zandesh et al., Piezoelectric electrospun nanofibrous energy harvesting devices: influence of the electrodes position and finite variation of dimensions. J. Ind. Text. 47(3), 348–362 (2017)

M.T. Todaro et al., Biocompatible, flexible, and compliant energy harvesters based on piezoelectric thin films. IEEE Trans. Nanotechnol. 17(2), 220–230 (2018)

Bafqi, M.S., et al., Expected lifetime of fibrous nanogenerator exposed to cyclic compressive pressure. 2020: p. 1528083720915835.

A. Gomez et al., Piezo-generated charge mapping revealed through direct piezoelectric force microscopy. Nat. Commun. 8(1), 1–10 (2017)

Y. Zhang et al., Enhanced pyroelectric and piezoelectric properties of PZT with aligned porosity for energy harvesting applications. J. Mater. Chem. A 5(14), 6569–6580 (2017)

M. Habib et al., Enhanced piezoelectric performance of donor La3+-doped BiFeO3–BaTiO3 lead-free piezoceramics. Ceram. Int. 46(6), 7074–7080 (2020)

Gao, J. et al., Recent progress on BaTiO3-based piezoelectric ceramics for actuator applications in Actuators. 2017. Multidisciplinary Digital Publishing Institute.

Azimi, B. et al., Electrospinning piezoelectric fibers for biocompatible devices. Adv Healthcare Mat. 2019: p. 1901287.

Azimi, B. et al., Electrospun ZnO/poly (vinylidene fluoride-trifluoroethylene) scaffolds for lung tissue engineering. 2020(ja).

S. Tiwari et al., Enhanced piezoelectric response in nanoclay induced electrospun PVDF nanofibers for energy harvesting. Energy Harvest. Syst. 171, 485–492 (2019)

S.M. Damaraju et al., Structural changes in PVDF fibers due to electrospinning and its effect on biological function. Biomed. Mater. 8(4), 045007 (2013)

S. Gee, B. Johnson, A. Smith, Optimizing electrospinning parameters for piezoelectric PVDF nanofiber membranes. J. Membr. Sci. 563, 804–812 (2018)

S. Gowthaman et al., A review on energy harvesting using 3D printed fabrics for wearable electronics. J Inst. Eng. 99(4), 435–447 (2018)

G. Zhang et al., Harvesting energy from human activity: ferroelectric energy harvesters for portable, implantable, and biomedical electronics. Energy Technol. 6(5), 791–812 (2018)

L. Ruan et al., Properties and applications of the β phase poly (vinylidene fluoride). Polymers 10(3), 228 (2018)

S. Khalid et al., A review of human-powered energy harvesting for smart electronics: Recent progress and challenges. Int. J. Precis. Eng. Manuf.-Green Technol. 6(4), 821–851 (2019)

A. Talbourdet et al., 3D interlock design 100% PVDF piezoelectric to improve energy harvesting. Smart Mater. Struct. 27(7): 075010 (2018)

T. Park et al., Highly conductive PEDOT electrodes for harvesting dynamic energy through piezoelectric conversion. J. Mater. Chem. A 2(15), 5462–5469 (2014)

J. Zhao, Z. You, A shoe-embedded piezoelectric energy harvester for wearable sensors. Sensors 14(7), 12497–12510 (2014)

D. Chen, T. Sharma, J.X. Zhang, Mesoporous surface control of PVDF thin films for enhanced piezoelectric energy generation. Sens. Actuators A 216, 196–201 (2014)

S. Jana et al., The influence of hydrogen bonding on the dielectric constant and the piezoelectric energy harvesting performance of hydrated metal salt mediated PVDF films. Phys. Chem. Chem. Phys. 17(26), 17429–17436 (2015)

J.-H. Lee et al., Highly sensitive stretchable transparent piezoelectric nanogenerators. Energy Environ. Sci. 6(1), 169–175 (2013)

Y. Cho et al., Enhanced energy harvesting based on surface morphology engineering of P (VDF-TrFE) film. Nano Energy 16, 524–532 (2015)

Z. Pi et al., Flexible piezoelectric nanogenerator made of poly (vinylidenefluoride-co-trifluoroethylene)(PVDF-TrFE) thin film. Nano Energy 7, 33–41 (2014)

V. Bhavanasi et al., Enhanced piezoelectric energy harvesting performance of flexible PVDF-TrFE bilayer films with graphene oxide. ACS Appl. Mater. Interfaces 8(1), 521–529 (2016)

M. Nuawi et al., Comparative study of whole-body vibration exposure between train and car passengers: a case study in malaysia. Int. J. Automot. Mech. Eng. 4, 490–503 (2011)

A. Ismail et al., Whole-body vibration exposure of Malaysian taxi drivers. Int. J. Automot. Mech. Eng. 11, 2786 (2015)

Mineto, A., et al., Modelling of a cantilever beam for piezoelectric energy harvesting. In: 9th Brazilian conference on Dynamics, control and their applications, Sao Carlos, 2010.

A.G. Muthalif, N.D. Nordin, Optimal piezoelectric beam shape for single and broadband vibration energy harvesting: Modeling, simulation and experimental results. Mech. Syst. Signal Process. 54, 417–426 (2015)

M. Salim et al., New simulation approach for tuneable trapezoidal and rectangular piezoelectric bimorph energy harvesters. Microsyst. Technol. 23(6), 2097–2106 (2017)

H.-C. Song et al., Multilayer piezoelectric energy scavenger for large current generation. J. Electroceram. 23(2–4), 301 (2009)

Zhu, D., et al., A bimorph multi-layer piezoelectric vibration energy harvester. 2010.

M.S. Woo et al., Study on increasing output current of piezoelectric energy harvester by fabrication of multilayer thick film. Sens. Actuators A 269, 524–534 (2018)

Y. Bai, H. Jantunen, J. Juuti, Energy harvesting research: the road from single source to multisource. Adv. Mater. 30(34), 1707271 (2018)

D.-J. Shin et al., Multi-layered piezoelectric energy harvesters based on PZT ceramic actuators. Ceram. Int. 41, S686–S690 (2015)

M. Safaei, H.A. Sodano, S.R. Anton, A review of energy harvesting using piezoelectric materials: state-of-the-art a decade later (2008–2018). Smart Mater. Struct. 28(11), 113001 (2019)

W.-S. Jung et al., Powerful curved piezoelectric generator for wearable applications. J. Nano Energy 13, 174–181 (2015)

K.-I. Park et al., Piezoelectric BaTiO3 thin film nanogenerator on plastic substrates. Nano Lett. 10(12), 4939–4943 (2010)

Bagherzadeh, R., et al., Flexible and stretchable nanofibrous piezo-and triboelectric wearable electronics.

Z. Yang et al., High-performance piezoelectric energy harvesters and their applications. Joule 2(4), 642–697 (2018)

S. Paquin, Y. St-Amant, Improving the performance of a piezoelectric energy harvester using a variable thickness beam. Smart Mater. Struct. 19(10), 105020 (2010)

Nguyen Thai, C., et al., On the nanoscale mapping of the mechanical and piezoelectric properties of poly (L-Lactic Acid) electrospun nanofibers. 2020.

S. Satapathy et al., Effect of annealing on phase transition in poly (vinylidene fluoride) films prepared using polar solvent. Bull. Mater. Sci. 34(4), 727 (2011)

L. Persano et al., High performance piezoelectric devices based on aligned arrays of nanofibers of poly (vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 4, 1633 (2013)

M.-H. You et al., A self-powered flexible hybrid piezoelectric–pyroelectric nanogenerator based on non-woven nanofiber membranes. J. Mater. Chem. A 6(8), 3500–3509 (2018)

A. Hartono et al., Effect of mechanical treatment temperature on electrical properties and crystallite size of PVDF Film. Adv. Mater. Phys. Chem. 3(1), 71–76 (2013)

J.I. Langford, A. Wilson, Scherrer after sixty years: a survey and some new results in the determination of crystallite size. J. Appl. Crystallogr. 11(2), 102–113 (1978)

Acknowledgements

The support provided by the ATMT Institute, Department of Electrical and Computer Engineering, Deakin University, University of Donghua, and INSF (Grant No 97016813) are highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yahyapour, R., Sorayani Bafqi, M.S., Latifi, M. et al. Hybrid multilayered piezoelectric energy harvesters with non-piezoelectric layers. J Mater Sci: Mater Electron 33, 1783–1797 (2022). https://doi.org/10.1007/s10854-021-07296-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07296-1