Abstract

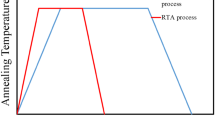

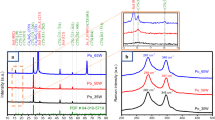

In this study, Cu2SnS3 (CTS) thin films prepared by a two-step sulfurization process were characterized. Cu and Sn metallic layers were first deposited on glass substrates by sputtering and then annealed in-situ while in the sputtering chamber to obtain CuSn (CT) alloys. This was followed by a pre-treatment step at temperatures between 200 and 350 °C in presence of S vapors. Finally, a full sulfurization step was performed at 525 °C to obtain the desired CTS phase. CTS films were characterized using EDX, XRD, Raman spectroscopy, SEM, optical transmission and Van der Pauw methods. It was found that all CTS samples had Cu-poor chemical composition. XRD data revealed only diffraction peaks belonging to CTS structure after the full sulfurization step. Raman spectra of the samples showed that except for the CTS sample pre-treated at 250 °C (CTS-250), which displayed the tetragonal crystal system, the films were dominated by the monoclinic structure. SEM surface images showed dense and polycrystalline microstructure, CTS-200 sample exhibiting a more uniform morphology. Optical band gap values were found to be ranging from 0.92 to 1.19 eV. All samples showed p-type conductivity but the sample pre-treated at 350 °C had higher resistivity and lower carrier concentration values. Overall, the CTS layer prepared using the pre-treatment step at 200 °C exhibited more promising structural and optical properties for potential photovoltaic applications. This work demonstrated that it is possible to change the crystal structure of sulfurized CTS thin films through a pre-treatment step.

Similar content being viewed by others

References

M. Nakamura, K. Yamaguchi, Y. Kimoto, Y. Yasaki, T. Kato, H. Sugimoto, IEEE J. Photovolt. 9, 1863–1867 (2019)

M.A. Green, E.D. Dunlop, J. Hohl-Ebinger, M. Yoshita, N. Kopidakis, X. Hao, Prog. Photovolt. Res. Appl. 28, 629–638 (2020)

H. Katagiri, N. Sasaguchi, S. Hando, S. Hoshino, J. Ohashi, T. Yokota, Sol. Energy Mater. Sol. Cells 49, 407–414 (1997)

W. Wang, M.T. Winkler, O. Gunawan, T. Gokmen, T.K. Todorov, Y. Zhu, D.B. Mitzi, Adv. Energy Mater. 4, 1301465 (2014)

I.D. Olekseyuk, I.V. Dudchak, L.V. Piskach, J. Alloy Compd. 368, 135–143 (2004)

M.A. Olgar, M. Tomakin, T. Kucukomeroglu, E. Bacaksız, Mater. Res. Express 6, 056401 (2019)

P.A. Fernandes, P.M.P. Salomé, AFd. Cunha, J. Phys. D 43, 215403 (2010)

N. Aihara, H. Araki, A. Takeuchi, K. Jimbo, H. Katagiri, Physica Status Solidi (c) 10, 1086–1092 (2013)

T. Bayazıt, M.A. Olgar, T. Küçükömeroğlu, E. Bacaksız, M. Tomakin, J. Mater. Sci. 30, 1–7 (2019)

M. Olgar, Superlattice Microstruct. 106366 (2019)

J.Y. Lee, I.Y. Kim, M.P. Surywanshi, U.V. Ghorpade, D.S. Lee, J.H. Kim, Sol. Energy 145, 27–32 (2017)

U. Chalapathi, B. Poornaprakash, S.-H. Park, Vacuum 131, 22–27 (2016)

T. Raadik, M. Grossberg, J. Krustok, M. Kauk-Kuusik, A. Crovetto, R. Bolt Ettlinger, O. Hansen, J. Schou, Appl. Phys. Lett. 110, 261105 (2017)

M.H. Sayed, E.V.C. Robert, P.J. Dale, L. Gütay, Thin Solid Films 669, 436–439 (2019)

E.V. Robert, J. De Wild, P.J. Dale, Cu2SnS3-based thin film solar cell from electrodeposition-annealing route, 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), IEEE, pp. 1–4 (2015)

A. Cho, S. Banu, Y. Cho, S.K. Ahn, J.H. Yun, J.-S. Cho, Sol. Energy 185, 131–145 (2019)

G. Nabi, F. Amin, J. Jacob, M.B. Tahir, M. Tanveer, Z. Usman, S. Hussain, Phys. B 602, 412498 (2021)

E.K. Ozsoy, F. Atay, O. Buyukgungor, Sol. Energy 214, 179–188 (2021)

P.R. Guddeti, P.M.B. Devi, K.R. Reddy, Chin. J. Phys. 67, 458–472 (2020)

W. Magdy, A. Kanai, F. Mahmoud, E. El Shenawy, S. Khairy, H. Hassan, M. Sugiyama, Jpn. J. Appl. Phys. 59, 105503 (2020)

G. Yang, X. Li, X. Ji, X. Xu, A. Wang, J. Huang, Y. Zhu, G. Pan, S. Cui, Sol. Energy 208, 206–211 (2020)

H.D. Shelke, A.C. Lokhande, J.H. Kim, C.D. Lokhande, J. Alloy Compd. 831, 154768 (2020)

E. Zaretskaya, V. Gremenok, V. Ivanov, A. Stanchik, O. Borodavchenko, D. Zhyhulin, S. Özçelik, N. Akçay, J. Appl. Spectrosc. 87, 488–494 (2020)

Y. Zhao, L. Chang, X.-F. Dong, H.-X. Zhang, Y. Li, J.-B. Chen, Sol. Energy 201, 190–194 (2020)

M.A. Olgar, Superlattice Microstruct. 138, 106366 (2020)

M. Umehara, S. Tajima, Y. Aoki, Y. Takeda, T. Motohiro, Appl. Phys. Express 9, 072301 (2016)

J. Chantana, K. Tai, H. Hayashi, T. Nishimura, Y. Kawano, T. Minemoto, Sol. Energy Mater. Sol. Cells 206, 110261 (2020)

S. Rahaman, M.K. Singha, M.A. Sunil, K. Ghosh, Superlattice Microst. 106589 (2020)

Y. Zhao, X. Han, B. Xu, C. Dong, J. Li, X. Yan, J. Mater. Sci.: Mater. Electron. 30, 17947–17955 (2019)

Y.S. Ocak, Mater. Res. Express 6, 126443 (2020)

M.R. Pallavolu, C.-D. Kim, V.R.M. Reddy, S. Gedi, C. Park, Sol. Energy 188, 209–217 (2019)

R. Bodeux, J. Leguay, S. Delbos, Thin Solid Films 582, 229–232 (2015)

M. He, A.C. Lokhande, I.Y. Kim, U.V. Ghorpade, M.P. Suryawanshi, J.H. Kim, J. Alloy Compd. 701, 901–908 (2017)

M.S. Abdel-Latif, W. Magdy, T. Tosuke, A. Kanai, A. Hessein, N. Shaalan, K. Nakamura, M. Sugiyama, A. Abdel-Moniem, J. Mater. Sci. 31, 14577–14590 (2020)

E.S. Hossain, P. Chelvanathan, S.A. Shahahmadi, B. Bais, M. Akhtaruzzaman, S.K. Tiong, K. Sopian, N. Amin, Sol. Energy 177, 262–273 (2019)

Y. Dong, J. He, X. Li, Y. Chen, L. Sun, P. Yang, J. Chu, J. Alloy Compd. 665, 69–75 (2016)

Y. Dong, J. He, J. Tao, L. Sun, P. Yang, J. Chu, J. Mater. Sci. 26, 6723–6729 (2015)

Y. Dong, X. Lu, P. Shen, Y. Chen, F. Yue, P. Xiang, L. Sun, P. Yang, J. Chu, Mater. Sci. Semicond. Process. 84, 124–130 (2018)

Y. Liu, J. Xu, Y. Yang, Z. Xie, J. Renew. Sustain. Energy 11, 023501 (2019)

M.A. Olgar, J. Klaer, R. Mainz, L. Ozyuzer, T. Unold, Thin Solid Films 628, 1–6 (2017)

M.A. Olgar, B.M. Basol, M. Tomakin, A. Seyhan, E. Bacaksiz, Mater. Sci. Semicond. Process. 88, 234–238 (2018)

L.L. Baranowski, K. McLaughlin, P. Zawadzki, S. Lany, A. Norman, H. Hempel, R. Eichberger, T. Unold, E.S. Toberer, A. Zakutayev, Phys. Rev. Appl. 4, 044017 (2015)

J. De Wild, E.V. Robert, B. El Adib, D. Abou-Ras, P.J. Dale, Sol. Energy Mater. Sol. Cells 157, 259–265 (2016)

A. Patterson, Phys. Rev. 56, 978 (1939)

D.M. Berg, R. Djemour, L. Gütay, S. Siebentritt, P.J. Dale, X. Fontane, V. Izquierdo-Roca, A. Pérez-Rodriguez, Appl. Phys. Lett. 100, 192103 (2012)

P.K. Sarswat, M. Snure, M.L. Free, A. Tiwari, Thin Solid Films 520, 1694–1697 (2012)

U. Chalapathi, Y. Jayasree, S. Uthanna, V. Sundara Raja, Physica Status Solidi (a) 210, 2384–2390 (2013)

D.M. Berg, R. Djemour, L. Gütay, G. Zoppi, S. Siebentritt, P.J. Dale, Thin Solid Films 520, 6291–6294 (2012)

M. Nakashima, J. Fujimoto, T. Yamaguchi, M. Izaki, Appl. Phys. Express 8, 042303 (2015)

Y.-X. Guo, W.-J. Cheng, J.-C. Jiang, J.-H. Chu, J. Mater. Sci. 27, 4636–4646 (2016)

H. Guan, H. Shen, C. Gao, X. He, J. Mater. Sci. 24, 1490–1494 (2013)

M. Umehara, Y. Takeda, T. Motohiro, T. Sakai, H. Awano, R. Maekawa, Appl. Phys. Express 6, 045501 (2013)

M. Kamalanathan, H. Shamima, R. Gopalakrishnan, K. Vishista, Mater. Technol. 33, 72–78 (2018)

B. Patel, R.K. Pati, I. Mukhopadhyay, A. Ray, J. Anal. Appl. Pyrol. 136, 35–43 (2018)

Acknowledgements

We gratefully acknowledge the help of A.O. Sarp with sample preparation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Olgar, M.A., Başol, B.M., Tomakin, M. et al. Phase transformation in Cu2SnS3 (CTS) thin films through pre-treatment in sulfur atmosphere. J Mater Sci: Mater Electron 32, 10018–10027 (2021). https://doi.org/10.1007/s10854-021-05660-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05660-9