Abstract

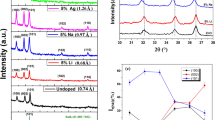

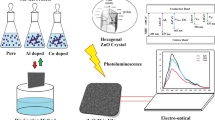

This study deals with the influence of the concentration and ionic radius of the bivalent dopant on the structural, morphological and optical properties of the sol–gel-derived ZnO thin films. For that, different concentrations of dopants with different radii (Ni2+, Cu2, Fe2+) have been chosen to synthesize many ZnO thin films. The X-ray diffraction confirms that all the obtained films exhibit a pure hexagonal wurtzite structure. Meanwhile, it appears that both the preferential film orientation and the crystal quality are strongly affected when varying the ionic radius or the concentration of dopant. We note also that the lattice parameters decrease when the electronegativity of the dopant increases. This behavior has been explained at the light of a simple schematic model, based on the electrostatic forces involved in chemical bonding. The Scherer formula reveals that the average size of the crystallites is ranged between 20 and 35 nm. On the other hand, as confirmed by the SEM analysis, all the deposited films present a compact, uniform and nanocrystalline morphology. Nonetheless, the optical analysis indicates that the Ni- and Fe-doped films are highly transparent (greater than 90%) in the visible region, while the Cu-doped ones exhibit the lowest transmission (about 76%). Additionally, a blue shift of the bandgap is noticed when doping with Ni or Fe, whereas the doping with Cu induces a red shift.

Similar content being viewed by others

References

R. Bekkari, L. Laânab, D. Boyer, R. Mahiou, B. Jaber, Mater. Sci. Semicond. Process. 71, 181–187 (2017)

D. Sivaganesh, S. Saravanakumar, V. Sivakumar, K.S.S. Ali, E. Akapo, E. Alemayehu, R. Rajajeyaganthan, R. Saravanan, J. Mater. Sci. Mater. Electron. 30, 2966 (2019)

X. Wei, B. Man, C. Xue, C. Chen, M. Liu, Jpn. J. Appl. Phys. 45, 8586 (2006)

A. Mallick, D. Basak, Prog. Mater. Sci. 96, 86 (2018)

V.L. Patil, S.A. Vanalakar, P.S. Patil, J.H. Kim, Sens. Actuators B Chem. 239, 1185 (2017)

R. Haarindraprasad, U. Hashim, S.C.B. Gopinath, M. Kashif, P. Veeradasan, S.R. Balakrishnan, K.L. Foo, P. Poopalan, Y.K. Mishra, PLoS ONE 10, 1 (2015)

P.S. Shewale, Y.S. Yu, J. Alloys Compd. 654, 79 (2016)

V. Kumar, O.M. Ntwaeaborwa, H.C. Swart, J. Colloid Interface Sci. 465, 295 (2016)

M. Karimipour, M. Sadeghian, M. Molaei, J. Mater. Sci. Mater. Electron. 29, 13782 (2018)

M. Huang, S. Wang, G. Wan, X. Zhang, Y. Zhang, K. Ou, L. Yi, J. Mater. Sci. Mater. Electron. 29, 7213 (2018)

M. Xin, J. Theor. Appl. Phys. 12, 177 (2018)

M. Murugesan, D. Arjunraj, J. Mayandi, V. Venkatachalapathy, J.M. Pearce, Mater. Lett. 222, 50 (2018)

S. Zhang, N.D. Pham, T. Tesfamichael, J. Bell, H. Wang, Sustain. Mater. Technol. 18, e00078 (2018)

Z.N. Kayani, H. Bashir, S. Riaz, S. Naseem, Mater. Res. Bull. 115, 121 (2019)

S.I. Shanthi, S. Poovaragan, M.V. Arularasu, S. Nithya, R. Sundaram, C.M. Magdalane, K. Kaviyarasu, M. Maaza, J. Nanosci. Nanotechnol. 18, 5441 (2018)

M. Wu, S. Yu, G. Chen, L. He, L. Yang, W. Zhang, Appl. Surf. Sci. 324, 791 (2015)

T. Wakano, N. Fujimura, Y. Morinaga, N. Abe, A. Ashida, T. Ito, Phys. E Low-Dimens. Syst. Nanostruct. 10, 260 (2001)

K.T. Kim, G.H. Kim, J.C. Woo, C.I. Kim, Surf. Coatings Technol. 202, 5650 (2008)

M.G. Nair, M. Nirmala, K. Rekha, A. Anukaliani, Mater. Lett. 65, 1797 (2011)

H. Chen, J. Ding, S. Ma, Superlattices Microstruct. 49, 176 (2011)

S. Singhal, J. Kaur, T. Namgyal, R. Sharma, Phys. B Condens. Matter. 407, 1223 (2012)

H. Gómez-Pozos, E.J.L. Arredondo, A.M. Álvarez, R. Biswal, Y. Kudriavtsev, J.V. Pérez, Y.L. Casallas-Moreno, M.L.O. Amador, Materials (Basel) 9, 87 (2016)

P. Jongnavakit, P. Amornpitoksuk, S. Suwanboon, N. Ndiege, Appl. Surf. Sci. 258, 8192 (2012)

U. Alver, T. Kilinç, E. Bacaksiz, S. Nezir, Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 138, 74 (2007)

D. Ali, M.Z. Butt, B. Arif, A.A. Al-Ghamdi, F. Yakuphanoglu, Phys. B Condens. Matter 506, 83 (2017)

O. Dimitrov, D. Nesheva, V. Blaskov, I. Stambolova, S. Vassilev, Z. Levi, V. Tonchev, Mater. Chem. Phys. 148, 712–719 (2014)

R. Bekkari, B. Jaber, H. Labrim, M. Ouafi, N. Zayyoun, L. Laânab, Int. J. Photoenergy 2019, 1 (2019)

J.P. Mathew, G. Varghese, J. Mathew, S.O.P. Trans, Appl. Phys. 1, 27 (2014)

K. Joshi, M. Rawat, S.K. Gautam, R.G. Singh, R.C. Ramola, F. Singh, J. Alloys Compd. 680, 252 (2016)

T. Srinivasulu, K. Saritha, K.T.R. Reddy, Mod. Electron. Mater. 3, 76–85 (2017)

B.R. Kumar, T.S. Rao, Dig. J. Nanomater. Bios. 6, 1281 (2011)

A. Sreedhar, J.H. Kwon, J. Yi, J.S. Kim, J.S. Gwag, Mater. Sci. Semicond. Process. 49, 8 (2016)

R. Bekkari, L. Laânab, B. Jaber, J. Chem. 4, 2289 (2016)

A.A. Othman, M.A. Ali, E.M.M. Ibrahim, M.A. Osman, J. Alloys Compd. 683, 399 (2016)

R. Raji, K.G. Gopchandran, Mater. Res. Express 4, 025002 (2017)

K. Ahn, T. Deutsch, Y. Yan, C. Jiang, C.L. Perkins, K. Ahn, T. Deutsch, Y. Yan, C. Jiang, C.L. Perkins, J. Turner, M. Al-jassim, J. Appl. Phys. 102, 023517 (2007)

G. Li, X. Zhu, X. Tang, W. Song, Z. Yang, J. Dai, Y. Sun, X. Pan, S. Dai, J. Alloys Compd. 509, 4816 (2011)

M. Öztas, M. Bedir, Thin Solid Films 516, 1703 (2008)

G. Li, X. Zhu, H. Lei, W. Song, Z. Yang, J. Dai, Y. Sun, X. Pan, S. Dai, J. Alloys Compd. 505, 434 (2010)

F. Boudjouan, A. Chelouche, T. Touam, D. Djouadi, Y. Ouerdane, Mater. Sci. Semicond. Process. 41, 382–389 (2016)

J.A. Najim, J.M. Rozaiq, Int. Lett. Chem. Phys. Astron. 15, 137 (2013)

Y.S. Kim, W.P. Tai, S.J. Shu, Thin Solid Films 491, 153 (2005)

R.K. Rajakarthikeyan, S. Muthukumaran, Opt. Mater. (Amst). 69, 382–391 (2017)

R.A. Rakkesh, S. Balakumar, Process. Appl. Ceram. 8, 7–13 (2014)

Acknowledgements

The authors wish to thank the National Center of Scientific and Technical Research (CNRST) and the staff of the UATRS Division, for use of their equipment and technical assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bekkari, R., Laânab, L. & Jaber, B. Effect of the bivalent dopant ionic radius, electronegativity and concentration on the physical properties of the sol–gel-derived ZnO thin films. J Mater Sci: Mater Electron 31, 15129–15139 (2020). https://doi.org/10.1007/s10854-020-04078-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04078-z