Abstract

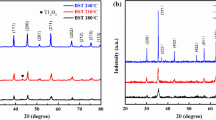

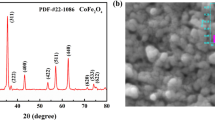

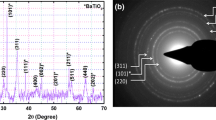

CoFe2O4 particles with two different sizes were prepared using hydrothermal method by controlling the technological parameters. On that basis, core–shell structure CoFe2O4@BaTiO3 (CFO@BTO) particles were prepared by sol–gel process. The surfactant treated composite particles were then distributed into a highly-insulating heptane to form CFO@BTO composite fluids. Influences of CFO particle size on the magnetodielectric and magnetoelectric coupling effect were comparatively investigated. XRD, TEM and SAED results indicate that the size of CFO particles are ~ 12 and ~ 18 nm, respectively, while the prepared CFO@BTO particles show bi-phase and core–shell composite structure, and the size of CFO@BTO particles are ~ 28 and ~ 35 nm, respectively. The composite fluids show quasi super paramagnetic behavior at room temperature due to the size effect and Brovnian motion. When the size of CFO is 18 nm, the CFO@BTO composite fluids shows larger remnant magnetization and coercive field. Strong dependence of dielectric properties on external magnetic field has been observed, of which the composite fluids show negative magnetodielectric effect, and the value of permittivity was decreased by 8% at 500 Oe. When size of CFO is 12 nm, the corresponding specimen with shows more obvious magnetic response, and it has larger remnant polarization. The values of both coercive electric field and remnant polarization of the two kinds of CFO@BTO composite fluids have been enhanced distinctly under the action of external magnetic field. When the particle size of CFO is smaller, the magnetolectric coupling coefficient αE of CFO@BTO composite fluid is larger, and this value decreases with increasing external magnetic field. When the particle sizes of CFO are 12 and 18 nm, the maximal values of αE are about 7 and 10 V/cm·Oe, respectively. These values are several orders of magnitude larger than that of CFO/BTO and other magnetoelectric composite ceramics. The strong coupling effect can be explained based on the formation, movement and variation of chain-like structure in the presence of external field. These results may supply useful information for enhancing coupling effect and might play important roles in practical applications in novel magnetoelectric devices.

Similar content being viewed by others

References

R.L. Gao, Z.H. Wang, G. Chen, X.L. Deng, W. Cai, C.L. Fu, Ceram. Int. 44, S84–S87 (2018)

X.Y. Gao, L.G. Li, D. Zhang, X.J. Wang, J. Jian, Z.H. He, H.Y. Wang, Nanoscale 12(10), 5914–5921 (2020)

R.L. Gao, H.W. Yang, Y.S. Chen, J.R. Sun, Y.G. Zhao, B.G. Shen, J. Alloy. Compd. 591, 346 (2014)

R.C. Xu, Z.H. Wang, R.L. Gao, S.L. Zhang, Q.W. Zhang, Z.D. Li, C.Y. Li, G. Chen, X.L. Deng, W. Cai, C.L. Fu, J. Mater. Sci. Mater. Electron. 29, 16226–16237 (2018)

R.L. Gao, Y.S. Chen, J.R. Sun, Y.G. Zhao, J.B. Li, B.G. Shen, J. Appl. Phys. 113, 183501 (2013)

H. Wang, Y.Y. Dai, Z.R. Liu, Q.D. Xie, C. Liu, W.N. Lin, L. Liu, P. Yang, J. Wang, T.V. Venkatesan, G.M. Chow, H. Tian, Z.D. Zhang, J.S. Chen, Adv. Mater. 32(8), 1904415 (2020)

R.L. Gao, Z.Y. Xu, L. Bai, Q.M. Zhang, Z.H. Wang, W. Cai, G. Chen, X.L. Deng, X.L. Cao, X.D. Luo, C.L. Fu, Adv. Electron. Mater. 4(6), 1800030 (2018)

K.K. Mishra, A.A. Instan, S. Kumari, J.F. Scott, R.S. Katiyar, Sci. Rep. 10, 2991 (2020)

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, W. Cai, G. Chen, X.L. Deng, X.L. Cao, X.D. Luo, C.L. Fu, Nanoscale 10(25), 11750–11759 (2018)

Z.Y. Xiao, R.L. Conte, M.G. Goikoetxea, R.V. Chopdekar, C.H. Lambert, X. Li, A.T. N'Diaye, P. Shafer, S. Tiwari, A. Barra, A. Chavez, K.P. Mohanchandra, G.P. Carman, K. Wang, S. Salahuddin, E. Arenholz, J. Bokor, R.N. Candler, ACS Appl. Mater. Interfaces. 12(5), 6752–6760 (2020)

H. Wu, R.C. Xu, X.F. Qin, R.L. Gao, S.L. Zhang, C. Zhou, S.L. Xing, W. Cai, J. Mater. Sci. Mater. Electron. 31, 885–895 (2019)

R.L. Gao, Q.Z. Leng, Z.H. Wang, G. Chen, C.L. Fu, X.L. Deng, W. Cai, Mater. Res. Express. 6, 026308 (2019)

J.P. Peters, N.C. Bristowe, D. Rusu, G. Apachitei, R. Beanland, M. Alexe, A.M. Sanchez, ACS Appl. Mater. Interfaces. 12(9), 10657–10663 (2020)

C. Liu, F. An, P.S.M. Gharavi, Q.W. Lu, J.K. Zha, C. Chen, L.M. Wang, X.Z. Zhan, Z.D. Xu, Y. Zhang, K. Qu, J.M. Yao, Y. Ou, Z.M. Zhao, X.L. Zhong, D.W. Zhang, N. Valanoor, L. Chen, T. Zhu, D.Y. Chen, X.F. Zhai, P. Gao, T.T. Jia, S.H. Xie, G.K. Zhong, J.Y. Li, Natl. Sci. Rev. 7(1), 84–91 (2020)

R.C. Xu, S.L. Zhang, F.Q. Wang, Q.W. Zhang, Z.D. Li, Z.H. Wang, R.L. Gao, C.L. Fu, J. Electron. Mater. 48(1), 386–400 (2019)

R.G. Cai, V.A. Antohe, B. Nysten, L. Piraux, A.M. Jonas, Adv. Func. Mater. 30(8), 1910371 (2020)

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, G. Chen, X.L. Deng, C.L. Fu, W. Cai, Compos. B 166, 204–212 (2019)

F. Narita, M. Fox, Adv. Energy Mater. 20(5), 1700743 (2017)

X.Z. Chen, M. Hoop, N. Shamsudhin, T. Huang, B. Özkale, Q. Li, E. Siringil, F. Mushtaq, L.D. Tizio, B.J. Nelson, S. Pa, Adv. Mater. 29(8), 1605458 (2017)

H. Wu, R.C. Xu, X.F. Qin, R.L. Gao, Z.H. Wang, C.L. Fu, W. Cai, G. Chen, X.L. Deng, Appl. Phys. A 126, 94–104 (2020)

R.L. Gao, J. Li, S.N. Han, B.C. Wen, T.Z. Zhang, H. Miao, Q.M. Zhang, J. Exp. Nanosci. 7, 282 (2012)

Y.Z. Xue, R.C. Xu, Z.H. Wang, R.L. Gao, C.Y. Li, G. Chen, X.L. Deng, W. Cai, C.L. Fu, J. Electron. Mater. 48(8), 4806–4817 (2019)

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, G. Chen, C.L. Fu, X.L. Deng, W. Cai, ACS Appl. Electron. Mater. 1(7), 1120–1132 (2019)

J.M. Zhang, Y. Huang, L. Jin, F. Rosei, F. Vetrone, J.P. Claverie, ACS Appl. Mater. Interfaces. 9(9), 8142–8150 (2017)

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, C.L. Fu, G. Chen, X.L. Deng, X.D. Luo, Y. Qiu, Wei Cai. J. Mater. Sci. 30(11), 10256–10273 (2019)

W.M. Xia, J.H.G. Zhou, T.L. Hu, P.G. Ren, G.J. Zhu, Y.L. Yin, J.L. Li, Z.C. Zhang, Compos. Part A 131, 105805 (2020)

A. Ahlawat, A.A. Khan, P. Desmukh, M. Shirolkar, J.N. Li, H.Q. Wang, S. Satapathy, A.K. Karnal, Mater. Lett. 261, 127082 (2020)

R.L. Gao, X.F. Qin, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, C.L. Fu, G. Chen, X.L. Deng, W. Cai, J. Alloy. Compd. 795, 501–512 (2019)

R.M. Thankachan, B. Raneesh, A. Mayeen, S. Karthika, S. Vivek, S.S. Nair, S. Thomas, N. Kalarikkal, J. Alloy. Compd. 731, 288–296 (2018)

A.R. Abraham, S. Joseph, M. Arif, P.M.G. Nambissan, D. Das, D. Rouxel, O.S. Oluwafemi, S. Thomas, N. Kalarikkal, Phys. Chem. Chem. Phys. 21, 8709–8720 (2019)

R.L. Gao, X.F. Qin, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, C.L. Fu, G. Chen, X.L. Deng, W. Cai, Mater. Chem. Phys. 232, 428–437 (2019)

N. Sheoran, V. Kumar, A. Kumar, J. Magn. Magn. Mater. 475, 30–37 (2019)

T. Woldu, B. Raneesh, B.K. Hazra, S. Srinath, P. Saravanan, M.V.R. Reddy, N. Kalarikkal, J. Alloy. Compd. 691, 644–652 (2017)

Acknowledgements

The present work has been supported by the Chongqing Research Program of Basic Research and Frontier Technology (CSTC2018jcyjAX0416, CSTC2019jcyj-msxmX0071), the Science and Technology Research Program of Chongqing Municipal Education Commission (KJZD-M201901501), the Scientific and Technological Research Young Program of Chongqing Municipal Education Commission (KJQN201801509, KJQN20190150), the Program for Creative Research Groups in University of Chongqing (Grant No. CXQT19031), the Innovation Program for Chongqing's Overseas Returnees (cx2019159), the Excellent Talent Project in University of Chongqing (Grant No. 2017-35), the Science and Technology Innovation Project of Social Undertakings and Peoples Livelihood Guarantee of Chongqing (cstc2017shmsA90015), the Leading Talents of Scientific and Technological Innovation in Chongqing (CSTCCXLJRC201919), the Program for Technical and Scientific Innovation Led by Academician of Chongqing, the Latter Foundation Project of Chongqing University of Science & Technology (CKHQZZ2008002), and the Scientific & Technological Achievements Foundation Project of Chongqing University of Science & Technology (CKKJCG2016328).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, R., Xue, Y., Wang, Z. et al. Effect of particle size on magnetodielectric and magnetoelectric coupling effect of CoFe2O4@BaTiO3 composite fluids. J Mater Sci: Mater Electron 31, 9026–9036 (2020). https://doi.org/10.1007/s10854-020-03436-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03436-1