Abstract

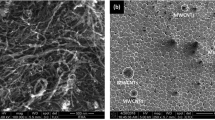

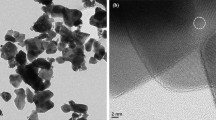

In this study, the joint effect of rice husk ash (RHA) reinforcement as an alternative silica source and electroless nickel immersion silver (ENIAg) surface finish on the intermetallic compound (IMC) formation and shear strength of the Sn–0.7Cu solder system was investigated. A series of plain and composite lead-free solder systems (Sn–0.7Cu−xRHA; x = 0, 0.01, 0.05 and 0.1 wt%) was successfully developed and subjected to reflow soldering on bare Cu and ENIAg surface finish. After conducting a comprehensive microstructural study using the scanning electron microscopy and energy dispersive spectroscopy techniques, the Cu6Sn5 and Cu3Sn intermetallic compound (IMC) phases were observed at the interface of the Sn–0.7Cu−xRHA/Cu composite solder joints. On the other hand, the (Cu,Ni)6Sn5 and Ni3Sn4 IMC phases dominated the interface of the Sn–0.7Cu−xRHA/ENIAg counterparts. Given the promising potential of the ENIAg surface finish, the Sn–0.7Cu−xRHA/ENIAg exhibited IMC thickness values within a range of 3.81–4.74 µm as compared to the 6.13–9.3 µm range exhibited by the Sn–0.7Cu−xRHA/Cu counterpart. More so, the ENIAg surface finish was effective in improving the shear strength of the plain solder joint, with the Sn–0.7Cu/ENIAg exhibiting 13.44 MPa relative to the 11.5 MPa exhibited by the Sn–0.7Cu/Cu counterpart. Overall, the strengthening effect of the RHA reinforcement was well marked in the Sn–0.7Cu−xRHA/Cu composite solder joints with the composite having 0.1 wt% RHA exhibiting the highest shear strength (14.6 MPa) across the board.

Similar content being viewed by others

References

T.T. Dele-Afolabi, M.A. Hanim, M. Norkhairunnisa, H.M. Yusoff, M.T. Suraya, Investigating the effect of isothermal aging on the morphology and shear strength of Sn-5Sb solder reinforced with carbon nanotubes. J. Alloys Compd. 649, 368–374 (2015)

K.M. Kumar, V. Kripesh, A.A. Tay, Single-wall carbon nanotube (SWCNT) functionalized Sn–Ag–Cu lead-free composite solders. J. Alloys Compd. 450(1–2), 229–237 (2008)

T.T. Dele-Afolabi, M.A. Hanim, M. Norkhairunnisa, M.T. Suraya, H.M. Yusoff, Influence of multi-walled carbon nanotubes on melting temperature and microstructural evolution of Pb-free Sn-5Sb/Cu solder joint, vol. 238, in IOP Conference Series: Materials Science and Engineering (IOP Publishing, Bristol, 2017). p. 012010

T. Wang, P. Zhou, F. Cao, H. Kang, Z. Chen, Y. Fu, Q. Yuan, Growth behavior of Cu6Sn5 in Sn–6.5 Cu solders under DC considering trace Al: in situ observation. Intermetallics 58, 84–90 (2015)

M.S. Gumaan, R.M. Shalaby, E.A.M. Ali, M. Kamal, Copper effects in mechanical, thermal and electrical properties of rapidly solidified eutectic Sn–Ag alloy. J. Mater. Sci.: Mater. Electron. 29(11), 8886–8894 (2018)

R.M. Shalaby, M. Kamal, E.A. Ali, M.S. Gumaan, Microstructural and mechanical characterization of melt spun process Sn-3.5 Ag and Sn-3.5 Ag-xCu lead-free solders for low cost electronic assembly. Mater. Sci. Eng. A 690, 446–452 (2017)

S. Xu, Y.C. Chan, K. Zhang, K.C. Yung, Interfacial intermetallic growth and mechanical properties of carbon nanotubes reinforced Sn3. 5Ag0. 5Cu solder joint under current stressing. J. Alloys Compd. 595, 92–102 (2014)

N. Bao, X. Hu, Y. Li, X. Jiang, Effects of thermal aging on growth behavior of interfacial intermetallic compound of dip soldered Sn/Cu joints. J. Mater. Sci.: Mater. Electron. 29(10), 8863–8875 (2018)

N. Mookam, K. Kanlayasiri, Evolution of intermetallic compounds between Sn-0.3 Ag-0.7 Cu low-silver lead-free solder and Cu substrate during thermal aging. J. Mater. Sci. Technol. 28(1), 53–59 (2012)

Q.K. Zhang, W.M. Long, Z.F. Zhang, Growth behavior of intermetallic compounds at Sn–Ag/Cu joint interfaces revealed by 3D imaging. J. Alloys Compd. 646, 405–411 (2015)

M. Abtew, G. Selvaduray, Lead-free solders in microelectronics. Mater. Sci. Eng. R 27(5–6), 95–141 (2000)

Y. Gao, C. Zou, B. Yang, Q. Zhai, J. Liu, E. Zhuravlev, C. Schick, Nanoparticles of SnAgCu lead-free solder alloy with an equivalent melting temperature of SnPb solder alloy. J. Alloys Compd. 484(1–2), 777–781 (2009)

Y.T. Chen, Y.T. Chan, C.C. Chen, Wettability and interfacial reactions between the molten Sn–3.0 wt% Ag–0.5 wt% Cu solder (SAC305) and Ni–Co alloys. J. Alloys Compd. 507(2), 419–424 (2010)

F.X. Che, W.H. Zhu, E.S. Poh, X.W. Zhang, X.R. Zhang, The study of mechanical properties of Sn–Ag–Cu lead-free solders with different Ag contents and Ni doping under different strain rates and temperatures. J. Alloys Compd. 507(1), 215–224 (2010)

A.K. Gain, T. Fouzder, Y.C. Chan, A. Sharif, N.B. Wong, W.K. Yung, The influence of addition of Al nano-particles on the microstructure and shear strength of eutectic Sn–Ag–Cu solder on Au/Ni metallized Cu pads. J. Alloys Compd. 506(1), 216–223 (2010)

X. Hu, Y. Li, Y. Liu, Z. Min, Developments of high strength Bi-containing Sn0. 7Cu lead-free solder alloys prepared by directional solidification. J. Alloys Compd. 625, 241–250 (2015)

W.Y. Chen, T.C. Chiu, K.L. Lin, Y.S. Lai, Electrorecrystallization of intermetallic compound in the Sn0. 7Cu solder joint. Intermetallics 26, 40–43 (2012)

A.A. El-Daly, A.E. Hammad, Enhancement of creep resistance and thermal behavior of eutectic Sn–Cu lead-free solder alloy by Ag and In-additions. Mater. Design 40, 292–298 (2012)

H. Gao, F. Wei, Y. Sui, J. Qi, Y. He, Q. Meng, Effect of nickel (Ni) on the growth rate of Cu 6 Sn 5 intermetallic compounds between Sn–Cu–Bi solder and Cu substrate. J. Mater. Sci.: Mater. Electron. 30(3), 2186–2191 (2019)

X. Hu, Y. Lai, X. Jiang, Y. Li, Effects of In addition on the wettability, interfacial characterization and properties of ternary Sn–Cu–Ni solders. J. Mater. Sci.: Mater. Electron. 29(21), 18840–18851 (2018)

A.K. Gain, Y.C. Chan, The influence of a small amount of Al and Ni nano-particles on the microstructure, kinetics and hardness of Sn–Ag–Cu solder on OSP-Cu pads. Intermetallics 29, 48–55 (2012)

H.Y. Jing, H.J. Guo, L.X. Wang, J. Wei, L.Y. Xu, Y.D. Han, Influence of Ag-modified graphene nanosheets addition into Sn–Ag–Cu solders on the formation and growth of intermetallic compound layers. J. Alloys Compd. 702, 669–678 (2017)

T.T. Dele-Afolabi, M.A. Hanim, O.J. Ojo-Kupoluyi, R. Calin, Impact of different isothermal aging conditions on the IMC layer growth and shear strength of MWCNT-reinforced Sn–5Sb solder composites on Cu substrate. J. Alloys Compd. 808, 151714 (2019)

Y. Wang, X. Zhao, X. Xie, Y. Gu, Y. Liu, Effects of nano-SiO 2 particles addition on the microstructure, wettability, joint shear force and the interfacial IMC growth of Sn3. 0Ag0. 5Cu solder. J. Mater. Sci.: Mater. Electron. 26(12), 9387–9395 (2015)

J.C. Leong, L.C. Tsao, C.J. Fang, C.P. Chu, Effect of nano-TiO 2 addition on the microstructure and bonding strengths of Sn3. 5Ag0. 5Cu composite solder BGA packages with immersion Sn surface finish. J. Mater. Sci.: Mater. Electron. 22(9), 1443–1449 (2011)

A. Yakymovych, Y. Plevachuk, P. Švec, D. Janičkovič, P. Šebo, N. Beronská, H. Ipser, Morphology and shear strength of lead-free solder joints with Sn3. 0Ag0. 5Cu solder paste reinforced with ceramic nanoparticles. J. Electron. Mater. 45(12), 6143–6149 (2016)

A. Ourdjini, M.A. Hanim, S.J. Koh, I.S. Aisha, K.S. Tan, Y.T. Chin (2007, November). Effect of solder volume on interfacial reactions between eutectic Sn–Pb and Sn–Ag–Cu solders and Ni (P)–Au surface finish, in 2006 Thirty-First IEEE/CPMT International Electronics Manufacturing Technology Symposium, IEEE, pp. 437–442

J.W. Yoon, S.B. Jung, Effect of surface finish on interfacial reactions of Cu/Sn–Ag–Cu/Cu (ENIG) sandwich solder joints. J. Alloys Compd. 448(1–2), 177–184 (2008)

K.K. Alaneme, K.O. Sanusi, Microstructural characteristics, mechanical and wear behaviour of aluminium matrix hybrid composites reinforced with alumina, rice husk ash and graphite. Eng. Sci. Technol. Int. J. 18(3), 416–422 (2015)

D.S. Prasad, C. Shoba, Hybrid composites–a better choice for high wear resistant materials. J. Mater. Res. Technol. 3(2), 172–178 (2014)

D.S. Prasad, C. Shoba, Experimental evaluation onto the damping behavior of Al/SiC/RHA hybrid composites. J. Mater. Res. Technol. 5(2), 123–130 (2016)

L.C. Tsao, S.Y. Chang, Effects of nano-TiO2 additions on thermal analysis, microstructure and tensile properties of Sn3. 5Ag0. 25Cu solder. Mater. Design 31(2), 990–993 (2010)

A.A. El-Daly, A.E. Hammad, Elastic properties and thermal behavior of Sn–Zn based lead-free solder alloys. J. Alloys Compd. 505(2), 793–800 (2010)

N. Dariavach, P. Callahan, J. Liang, R. Fournelle, Intermetallic growth kinetics for Sn–Ag, Sn–Cu, and Sn–Ag–Cu lead-free solders on Cu, Ni, and Fe–42Ni substrates. J. Electron. Mater. 35(7), 1581–1592 (2006)

M.M. Jubair, M.S. Gumaan, R.M. Shalaby, Reliable Sn–Ag–Cu lead-free melt-spun material required for high-performance applications. Z. Kristallogr. Cryst. Mater. 234(11–12), 757–767 (2019)

M.R. Adawiyah, O.S. Azlina, Comparative study on the isothermal aging of bare Cu and ENImAg surface finish for Sn–Ag–Cu solder joints. J. Alloys Compd. 740, 958–966 (2018)

J.W. Yoon, B.I. Noh, J.H. Yoon, H.B. Kang, S.B. Jung, Sequential interfacial intermetallic compound formation of Cu6Sn5 and Ni3Sn4 between Sn–Ag–Cu solder and ENEPIG substrate during a reflow process. J. Alloys Compd. 509(9), L153–L156 (2011)

Y. Liu, F. Sun, H. Zhang, T. Xin, C.A. Yuan, G. Zhang, Interfacial reaction and failure mode analysis of the solder joints for flip-chip LED on ENIG and Cu-OSP surface finishes. Microelectron. Reliab. 55(8), 1234–1240 (2015)

J. James, M.S. Rao, Reactivity of rice husk ash. Cem. Concr. Res. 16(3), 296–302 (1986)

G.C. Cordeiro, T. Filho, R.D. Tavares, L.M. Fairbairn, E. D. M. R., & S. Hempel, Influence of particle size and specific surface area on the pozzolanic activity of residual rice husk ash. Cem. Concr. Compos. 33(5), 529–534 (2011)

J.M. Kim, M.H. Jeong, S. Yoo, C.W. Lee, Y.B. Park, Effects of surface finishes and loading speeds on shear strength of Sn–3.0 Ag–0.5 Cu solder joints. Microelectron. Eng. 89, 55–57 (2012)

M. Sona, K.N. Prabhu, The effect of reflow time on reactive wetting, evolution of interfacial IMCs and shear strength of eutectic Sn–Cu solder alloy. J. Mater. Sci.: Mater. Electron. 25(3), 1446–1455 (2014)

Z. Fathian, A. Maleki, B. Niroumand, Synthesis and characterization of ceramic nanoparticles reinforced lead-free solder. Ceram. Int. 43(6), 5302–5310 (2017)

X.L. Zhong, M. Gupta, Development of lead-free Sn–0.7 Cu/Al2O3 nanocomposite solders with superior strength. J. Phys. D 41(9), 095403 (2008)

H. Fei, K. Yazzie, N. Chawla, H. Jiang, Modeling fracture of Sn-rich (Pb-free) solder joints under mechanical shock conditions. J. Electron. Mater. 41(8), 2089–2099 (2012)

Acknowledgements

The authors are thankful to the Research Management Center of Universiti Putra Malaysia for providing financial support (UPM- Grant Putra; UPM/700-2/1/GPBI/2017/9553600) to carry out this research study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional ailiations.

Rights and permissions

About this article

Cite this article

Hanim, M.A.A., Kamil, N.M., Wei, C.K. et al. Microstructural and shear strength properties of RHA-reinforced Sn–0.7Cu composite solder joints on bare Cu and ENIAg surface finish. J Mater Sci: Mater Electron 31, 8316–8328 (2020). https://doi.org/10.1007/s10854-020-03367-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03367-x