Abstract

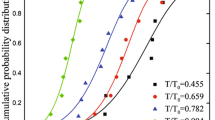

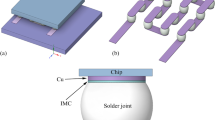

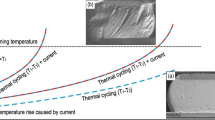

In this paper, the physical and mechanical properties of Sn–3.0Ag–0.5Cu (SAC305) solder and the thermal fatigue properties of solder joints under different electric current densities and heat sink temperatures are investigated. The thermal and electrical conductivities of the SAC305 specimens are measured for the electric current density between 6.37 × 102 A/cm2 and 2.55 × 103 A/cm2. Through comparisons against the experimental results, it is found that the prediction results of finite element simulations can reasonably characterize the mechanical properties of SAC305 solder materials. In order to evaluate the effect on mechanical behaviour of solder alloys, a typical solder joint of mechanical properties for the upper and lower bounds under thermo-electric coupling conditions are analyzed by finite element simulations. The original Coffin–Manson model is improved to predict the fatigue life of SAC305 solder joints under temperature cycling coupled with electric current. Comparisons show that the different mechanical behaviour of SAC305 solder materials results in different performances at varying electric current densities and heat sink temperatures. For low current densities and heat sink temperatures, the solder material with lower yielding and ultimate strengths has a higher fatigue life. On the contrary, at high current densities and heat sink temperatures, the solder material with higher yielding and ultimate strengths will exhibit advantages in terms of fatigue life. From the numerical simulation point of view, this study reveals the performance advantages of lead-free solders with higher yielding and ultimate strengths in terms of thermal fatigue and current density for high temperature and power applications.

Similar content being viewed by others

References

A. Michaelowa, F. Jotzo, Energy Policy 33, 511–523 (2005)

IPC-SM-785, Guidelines for Accelerated Reliability Testing of Surface Mount Solder Attachments (IPC, Northbrook, 1992)

T. Takemoto, in 6th International Conference on Electronics Packaging Technology (ICEPT), August 30-September 2, Shenzhen, China (2005)

EEC, D., in Directive of the European parliament and of the council on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS) (recast)

G. Lee, P. Liang, J. Lin, in International Microsystems, Packaging, Assembly & Circuits Technology Conference (IMPACT), 2008

Norway POHS, in Prohibition on Certain Hazardous Substances in Consumer Products, 2007

J. Nouri, S. Toutounchian, Int. J. Environ. Sci. Technol. 1, 109–117 (2004)

D.S. Steinberg, Preventing Thermal Cycling and Vibration Failures in Electronic Equipment (Wiley, Hoboken, 2001)

W. Yurkowsky, R.E. Schafter, J.M. Finkelstein, Accelerated Testing Technology, Technical Report No. RADC-TR-67-420 (Rome Air Development Center, 1967)

S. Özsoy, M. Çelik, F.S. Kadıoğlu, Eng. Fail. Anal. 15, 946–957 (2008)

H. Hirose, IEEE Trans. Reliab. 42, 650–657 (1993)

A.J. Watkins, IEEE Trans. Reliab. 43, 361–365 (1996)

J.A. Nachlas, Qual. Reliab. Eng. Int. 2, 3–6 (2010)

H. Cui, in Proceedings of 2005 International Conference on Reliability and Maintainability Symposium. (2005)

I. Shohji, H. Mori, Y. Orii, Microelectron. Reliab. 44, 269–274 (2004)

C.L. Liang, K.L. Lin, Mater. Charact. 145, 545–555 (2018)

Z. Zhang, X. Hu, X. Jiang, Y. Li, Metall. Mat. Trans. A. 50, 1–13 (2019)

Dassault Systemes Simulia Corp., ABAQUS User’s Manual 2017 (Hibbitt, Karlsson & Sorensen, Rhode Island, 2017)

Y. Yao, J. Fry, M.E. Fine, L.M. Keer, Acta Mater. 61, 1525–1536 (2013)

L. Qi, J. Zhao, X.M. Wang, L. Wang, in Proceedings of 2004 International Conference on the Business of Electronic Product Reliability and Liability, 2004

X. Long, Y. Liu, Y. Yao, F. Jia, C. Zhou, Y. Fu, Y. Wu, AIP Adv. 8, 085001 (2018)

X. Long, W. Tang, S. Wang, X. He, Y. Yao, J. Mater. Sci. Mater. Electron. 29, 7177–7187 (2018)

T.J. Kilinski, J.R. Lesniak, B.I. Sandor, Solder Joint Reliability: Theory and Applications (1991), pp. 384–405

J. Schijve, Mater. Sci. 25, 679–702 (2003)

R.P. Skelton, Metal Sci. J. 7, 427–440 (2013)

N. Bai, X. Chen, H. Gao, Mater. Des. 30, 122–128 (2009)

N. Bai, X. Chen, Int. J. Plast. 25, 2181–2203 (2009)

W. Engelmaier, IEEE Trans. Compon. Packag. Manuf. 6, 232–237 (2003)

W. Engelmaier, A.I. Attarwala, IEEE Trans. Compon. Packag. Manuf. 12, 284–296 (1989)

Z. Wen, H. Pei, H. Yang, Y. Wu, Z. Yue, Int. J. Fatigue 111, 243–255 (2018)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51508464 and U1537104), the Natural Science Foundation of Shaanxi Province (No. 2017JM1013), the Astronautics Supporting Technology Foundation of China (No. 2019-HT-XG), and the Fundamental Research Funds for the Central Universities (No. 3102018ZY015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Long, X., Liu, Y., Jia, F. et al. Thermal fatigue life of Sn–3.0Ag–0.5Cu solder joint under temperature cycling coupled with electric current. J Mater Sci: Mater Electron 30, 7654–7664 (2019). https://doi.org/10.1007/s10854-019-01081-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01081-x