Abstract

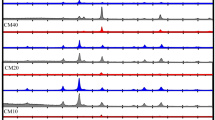

M-type hexagonal SrCoxFe12−xO19 (x = 0, 0.1, 0.2, and 0.3) have been synthesized by the ball-milling assisted ceramic process. The influence of Co substitutions on the crystalline structure, lattice strain, morphology, and magnetic behaviors has been investigated. The results show that a high-crystallized hexagonal SrCoxFe12−xO19 is obtained when the precursor is calcined at 950 °C in air for 3 h. Lattice parameters and grain size of SrCoxFe12−xO19 increase with the increase in substitution content (x). Hysteresis behavior varies with substitution content (x) and calcination temperature. M-type hexagonal SrCoxFe12−xO19 (x = 0, 0.1, and 0.2), calcined at 950 °C, with uniaxial anisotropy exhibits a broad M–H loop and rectangular shape. At higher calcination temperature (1050 and 1200 °C) or substitution content (x) is equal to 0.3, the character of the hysteresis loop of SrCoxFe12−xO19 changes from hard into semi-hard. The trend of specific saturation magnetization of SrCoxFe12−xO19, calcined at 950 °C, increases with the decrease in lattice strains. SrFe12O19, calcined at 950 °C, has the highest specific saturation magnetization value (91.30 emu/g) and magnetic moment (17.36 µ B). With the increase of calcination temperature, magnetic domain type of ferrites changes from a single magnetic domain to a multi-domain type.

Similar content being viewed by others

References

T.Y. Hwang, J. Lee, H.R. Lim, S.J. Jeong, G.H. An, J. Kim, Y.H. Choa, Ceram. Int. 43, 3879–3884 (2017)

F. Rhein, R. Karmazin, M. Krispin, T. Reimann, O. Gutfleisch, J. Alloys Compd. 690, 979–985 (2017)

M. Cernea, S.G. Sandu, C. Galassi, R. Radu, V. Kuncser, J. Alloys Compd. 561, 121–128 (2013)

R.C. Pullar, Prog. Mater. Sci. 57, 1191–1334 (2012)

S. Bierlich, F. Gellersenb, A. Jacob, J. Töpfer, Mater. Res. Bull. 86, 19–23 (2017)

G. Qiang, Y. Jin, X.W. Lu, X.P. Cui, D.M. Deng, B.J. Kang, W.G. Yang, S.X. Cao, J.C. Zhang, Appl. Phys. A 122, 681 (2016)

R.A. Pawar, S.S. Desai, Q.Y. Tamboli, S.E. Shirsath, S.M. Patange, J. Magn. Magn. Mater 378, 59–63 (2015)

J.R. Liu, R.Y. Hong, W.G. Feng, D. Badami, Y.Q. Wang, Powder Technol. 262, 142–149 (2014)

C.L. Lei, S.L. Tang, Y.W. Du, Ceram. Int. 42, 15511–15516 (2016)

L. Peng, L.Z. Li, R. Wang, Y. Hu, X.Q. Tu, X.X. Zhong, J. Magn. Magn. Mater 404, 170–174 (2016)

L. Lechevallier, J.M. Le Breton, J.F. Wang, I.R. Harris, J. Magn. Magn. Mater. 269, 192–196 (2004)

H. Mocuta, L. Lechevallier, J.M. Le Breton, J.F. Wang, I.R. Harris, J. Alloys Compd. 364, 48–52 (2004)

C.C. Liu, X.S. Liu, S.J. Feng, K.M.U. Rehman, M.L. Li, C. Zhang, H.H. Li, X.Y. Meng, J. Magn. Magn. Mater. 436, 126–129 (2017)

J. Singh, C. Singh, D. Kaur, S. Bindra Narang, R. Jotania, R. Joshi, J. Alloys Compd. 695, 792–798 (2017)

W. Onreabroy, K. Papato, G. Rujijanagul, K. Pengpat, T. Tunkasiri, Ceram. Int. 38, S415–S419 (2012)

X.S. Liu, L. Fernandez-Garcia, F. Hu, D.R. Zhu, M. Suárez, J.L. Menéndez, Mater. Chem. Phys. 133, 961–964 (2012)

J.H. Luo, Mater. Lett. 80, 162–164 (2012)

S.D. Kim, J.S. Kim, J. Magn. Magn. Mater. 307, 295–300 (2006)

T.T.V. Nga, N.P. Duong, T.D. Hien, J. Magn. Magn. Mater. 324, 1141–1146 (2012)

K. Alamelu Mangai, K. Tamizh Selvi, M. Priya, M. Rathnakumari, P. Sureshkumar, S. Sagadevan, J. Mater. Sci. 28, 2910–2922 (2017)

M. Zargar Shoushtari, S.E. Mousavi Ghahfarokhi, F. Ranjbar, J. Supercond. Nov. Magn. 28, 1601–1609 (2015)

S.E. Mousavi Ghahfarokhi, F. Ranjbar, M. Zargar Shoushtari, J. Magn. Magn. Mater. 349, 80–87 (2014)

A.L. Xia, C.H. Zuo, L. Chen, C.G. Jin, Y.H. Lv, J. Magn. Magn. Mater. 332, 186–191 (2013)

Z.P. Zhou, Z.Y. Wang, X.T. Wang, X.R. Wang, J.S. Zhang, F.K. Dou, M.L. Jin, J.Y. Xu, J. Alloys Compd. 610, 264–270 (2014)

L. Peng, L.Z. Li, R. Wang, Y. Hu, X.Q. Tu, X.X. Zhong, J. Alloys Compd. 656, 290–294 (2016)

B.K. Rai, S.R. Mishra, V.V. Nguyen, J.P. Liu, J. Alloys Compd. 581, 275–281 (2013)

W. Chen, W.W. Wu, M.M. Mao, C. Zhou, S.F. Zhou, M.Y. Li, Q. Wang, J. Supercond. Nov. Magn. 30, 707–714 (2017)

K.W. Zhou, W. Chen, X.H. Wu, W.W. Wu, C.W. Lin, J. Wu, J. Electron. Mater. 46, 4618–4626 (2017)

M.A. Amer, J. Magn. Magn. Mater. 426, 771–778 (2017)

X.H. Wu, W. Chen, W.W. Wu, Y.Y. Chen, T.W. Li, C.Y. Zhang, H.X. Zhang, J. Mater. Sci. 52, 10085–10097 (2017)

K.W. Zhou, X.H. Wu, W.W. Wu, J. Xie, S.Q. Tang, S. Liao, Adv. Powder Technol. 24, 359–363 (2013)

W. Chen, W.W. Wu, X.H. Wu, T.W. Li, J. Wu, H.X. Zhang, J. Mater. Sci. 28, 7874–7883 (2017)

Y. Zhou, X.H. Wu, W.W. Wu, X.S. Huang, W. Chen, Y.L. Tian, D. He, Mater. Sci. Semicond. Process 41, 162–167 (2016)

W. Chen, W.W. Wu, S.Q. Liu, J.W. Xu, D.S. Liu, X.H. Wu, Y. Zhou, J. Wu, Mater. Sci. Semicond. Process 39, 544–550 (2015)

Y.L. Chai, Y.S. Chang, G.J. Chen, Y.J. Hsiao, Mater. Res. Bull. 43, 1066–1073 (2008)

X.Z. Guo, H. Yang, M. Cao, C. Han, F.F. Song, Trans. Nonferrous Met. Soc. China 16, 593–597 (2006)

W. Chen, Y. Zhou, J.Y. Lu, X.S. Huang, W.W. Wu, C.W. Lin, Q. Wang, Ceram. Int. 42, 1114–1121 (2016)

W. Abbas, I. Ahmad, M. Kanwal, G. Murtaza, I. Ali, M.A. Khan, M.N. Akhtar, M. Ahmad, J. Magn. Magn. Mater. 374, 187–191 (2015)

V.C. Chavan, S.E. Shirsath, M.L. Mane, R.H. Kadam, S.S. More, J. Magn. Magn. Mater. 398, 32–37 (2016)

S.F. Kong, P.P. Zhang, X.F. Wen, P.H. Pi, J. Cheng, Z.R. Yang, J. Hai, Particuology 6, 185–190 (2008)

G. Mendoza-Suarez, L.P. Rivas-Vazquez, J.C. Corral-Huacuz, A.F. Fuentes, J.I. Escalante-Garcia, Physica B 339, 110–118 (2003)

K.K. Mallick, P. Shepherd, R.J. Green, J. Magn. Magn. Mater. 312, 418–429 (2007)

D.A. Vinnik, D.A. Zherebtsov, L.S. Mashkovtseva, S. Nemrava, A.S. Semisalova, D.M. Galimov, S.A. Gudkova, I.V. Chumanov, L.I. Isaenko, R. Niewa, J. Alloys Compd. 628, 480–484 (2015)

M.A. Amer, T.M. Meaz, S.S. Attalah, A.I. Ghoneim, J. Alloys Compd. 654, 45–55 (2016)

W. Chen, W.W. Wu, D.S. Liu, J. Wu, J. Mater. Sci. 28, 2901–2909 (2017)

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Grant No. 21603040) and the Guangxi Natural Science Foundation of China (Grant Nos. 2016GXNSFDA380034, 2016GXNSFBA380062).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, X., Chen, W., Wu, W. et al. Synthesis of hexagonal Co3+-substituted Sr-ferrites via ball-milling assisted ceramic process and their magnetic properties. J Mater Sci: Mater Electron 28, 18815–18824 (2017). https://doi.org/10.1007/s10854-017-7831-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7831-4