Abstract

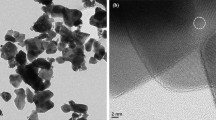

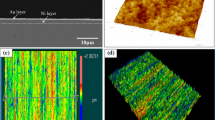

This paper investigates the growth behavior, morphology of intermetallic compound (IMC) layer and hardness of low melting temperature Sn–35Bi–1Ag (wt%) solders on different surface-finished Cu substrates i.e., immersion Ag (ImAg)-plated Cu and Ag/Ni-plated Cu substrates. From SEM observation, a scallop-shaped Cu6Sn5 IMC layer was found to adhere at initial reaction stage on Sn–Bi–Ag solders/ImAg-plated Cu substrate system. However, a very thin Cu3Sn IMC layer was clearly also observed between the Cu6Sn5 IMC layer and substrate after a lengthy reaction. On the other hand, in Sn–Bi–Ag solder and Ag/Ni-plated Cu substrate system, a scallop-shaped Ni3Sn4 IMC layer was observed at the interface without any Cu3Sn IMC layer formation. These IMC layers thicknesses were increased with increasing the reaction time and temperature. However, the growth behavior of Ni3Sn4 IMC layer was slower than that of Cu6Sn5 and Cu3Sn IMC layers. In solder ball regions, bright contrast Bi and needle-shaped Ag3Sn phases were clearly observed in the dark contrast β-Sn matrix in both type of solder systems. Furthermore, bright contrast Bi phase size was increased with the reaction time. However, in the Sn–35Bi–1Ag solder and Ag/Ni-plated Cu substrate system, the Bi phase appeared with fine microstructure as compared with the Sn–35Bi–1Ag solder/ImAg-plated Cu substrate system because the Ag layer dissolved into the molten solder and changed the diffusivity and chemical affinity. The hardness values of Sn–Bi–Ag solder joints on ImAg-plated Cu and Ag/Ni-plated Cu substrates after 5 min reaction at 230 °C were about 23.0 and 24.1 HV, respectively—and about 18.9 and 20.4 HV after 30 min reaction at 230 °C, respectively.

Similar content being viewed by others

References

R.L. Xu, Y.C. Liu, Y.J. Han, C. Wei, X. Wang, L.M. Yu, J. Mater. Sci. 20, 675 (2009)

P. Jiang, Y. Liu, C. Wei, J. Wan, R. Xu, Z. Gao, J. Mater. Sci. 20, 139 (2009)

F. Frongia, M. Pilloni, A. Scano, A. Ardu, C. Cannas, A. Musinu, G. Borzone, S. Delsante, R. Novakovic, G. Ennas, J. Alloys Compd. 623, 7 (2015)

S. Chellvarajoo, M.Z. Abdullah, Z. Samsudin, Mater. Des. 67, 197 (2015)

B. Kim, C.W. Lee, D. Lee, N. Kang, J. Alloys Compd. 592, 207 (2014)

X. Li, F. Zua, W. Gao, X. Cui, L. Wang, G. Ding, Appl. Surf. Sci 258, 5677 (2012)

A.K. Gain, L. Zhang, Y.C. Chan, J. Mater. Sci. 26, 7039 (2015)

X. Hua, W. Chen, B. Wu, Mater. Sci. Eng. 556, 816 (2012)

L. Zhang, K.N. Tu, Mater. Sci. Eng. 82, 1 (2014)

T. Fouzder, A.K. Gain, Y.C. Chan, A. Sharif, W.K.C. Yung, Microelectron. Reliab. 50, 2051 (2010)

A.K. Gain, L. Zhang, M.Z. Quadir, Mater. Des. 110, 275 (2016)

T. Fouzder, Q. Li, Y.C. Chan, D.K. Chan, J. Mater. Sci. 25, 2529 (2014)

A.K. Gain, Y.C. Chan, W.K.C. Yung, Mater. Sci. Eng. 162, 92 (2009)

J.E. Lee, K.S. Kim, M. Inoue, J. Jiang, K. Suganuma, J. Alloys Compd. 454, 310 (2008)

H. Li, H. Hanna, Wuhan Univ. J. Nat. Sci. 17(1), 79 (2012)

C. Jiqing, Electroplat. Pollut. Control 16(4), 10–12 (1996) (Ch)

Y.C. Chan, D. Yang, Prog. Mater. Sci. 55, 428 (2010)

A.K. Gain, T. Fouzder, Y.C. Chan, W.K.C. Yung, J. Alloys Compd. 509, 3319 (2011)

C.C. Chang, Y.W. Lin, Y.W. Wang, C.R. Kao, J. Alloys Compd. 492, 99 (2010)

F. Cheng, F. Gao, H. Nishikawa, T. Takemoto, J. Alloys Compd. 472, 530 (2009)

M. Sona, K.N. Prabhu, J. Mater. Sci. 25, 1446 (2014)

Q.V. Bui, S.B. Jung, J. Mater. Sci. 25, 423 (2014)

B.L. Silva, N. Cheung, A. Garcia, J.E. Spinelli, Mater. Lett. 142, 163 (2015)

L. Wang, D.Q. Yu, J. Zhao, M.L. Huang, Mater. Lett. 56, 1039 (2002)

V. Kripesh, M. Teo, C.T. Tai, G. Vishwanadam, Y.C. Mui, in Proceedings of the 51st Electronic Components and Technology Conference, pp. 665–670, June 2001

G. Ghosh, Acta Mater. 49, 2609 (2001)

T. Fouzder, Y.C. Chan, D.K. Chan, J. Mater. Sci 25, 5375 (2014)

A.K. Gain, Y.C. Chan, Intermetallics 29, 48 (2012)

P. Liu, P. Yao, J. Liu, J. Alloys Compd. 486, 474 (2009)

Acknowledgements

The authors would like to acknowledge the financial support provided by Chartermate Electronics Ltd., Hong Kong. The authors would also like to thank EPA Centre members, City University of Hong Kong, for using the facility to prepare the sample and SEM observation. Prof. Richard De La Rue is thanked for proof reading the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fouzder, T., Gain, A.K. & Chan, D.K. Microstructure, wetting characteristics and hardness of tin-bismuth-silver (Sn–Bi–Ag) solders on silver (Ag)-surface finished copper (Cu) substrates. J Mater Sci: Mater Electron 28, 16921–16931 (2017). https://doi.org/10.1007/s10854-017-7611-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7611-1