Abstract

The CdCl2 treatment used in the development of high efficiency CdTe solar cells is an essential processing step but remains fully unexplored. What really happens during this treatment is not yet fully understood. The changes in doping concentrations during this processing step are a key parameter to investigate. Determination of the position of the Fermi level (FL) is a good method to explore these changes and therefore photoelectrochemical cell method and ultraviolet photoelectron spectroscopy method have been used to investigate these trends. Four different CdTe layers prepared by electroplating have been used for this investigation. The overall observations indicate the settling down of the FL in the upper half of the bandgap after CdCl2 treatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Heat treatment of CdTe thin films in the presence of CdCl2 is a key step in fabricating high efficiency solar cells. Re-crystallisation to form large grains and defect passivation have been experimentally observed but the doping effects on the CdTe material have not been examined in detail [1]. The doping effects are key in electronic device performance, and therefore this is an important area needing careful experimentation in order to improve understanding of this crucial processing step.

The formation of a photovoltaic active rectifying junction in any solar cell mainly depends on the type (n-type or p-type) of the materials used, and the level of doping concentration of the main absorber layer, CdTe. The formation of a healthy depletion region in the junction mainly depends on the doping concentration. During the past few decades, the CdTe used in solar cell fabrication has been assumed to be p-type and therefore the junction was considered as a simple p–n junction. Since the CdTe material can exists in both n- and p-type electrical conduction forms, it is essential to know the type of the materials used and the doping concentrations, before critical analysis and interpretation of any experimental results. The photoelectrochemical (PEC) and ultraviolet photoelectron spectroscopy (UPS) measurements enable the scientists to find the electrical conductivity type of a semiconducting material. Furthermore, the position of the Fermi level (FL) is an indirect method to find the electrical conductivity type and estimate doping levels of the material. Electronic devices cannot be developed without knowing the electrical conductivity type and doping levels of the materials used.

Our most recent work with PEC cell measurements on as-deposited and CdCl2-treated CdTe produced some illuminating results [1, 2]. This work showed that the n-CdTe layers gradually move towards p-type, and p-CdTe layers gradually move towards n-type during the CdCl2 treatment of electrodeposited CdTe layers. This indicates a drastic doping effect, causing the movement of FL across the CdTe bandgap. To confirm this FL movement across the forbidden bandgap, UPS has been used to determine the position of the FL as a function of CdCl2 treatment. The results from PEC and UPS studies are presented and discussed in this communication.

2 Experimental

2.1 Growth of CdTe layers by electroplating

The CdTe layers used in this work were electrodeposited on glass/FTO (Flourine doped Tin Oxide)/CdS surfaces using aqueous solutions containing Cd-precursor and TeO2 solution. pH value was maintained at 2.00 at the start of the growth and temperature was raised to 85 °C for 2-electrode system and to 70 °C for 3-electrode system. A dilute TeO2 solution was added to the electrolyte at regular intervals in order to maintain a low level of Te ions in the deposition bath. Four different CdTe layers used in this work were grown using CdSO4 [3], Cd(NO3)2 [4] and CdCl2 [5] as precursors for Cd ions. The structures of the layers investigated using PEC cell and UPS were glass/FTO/CdTe and glass/FTO/CdS/CdTe respectively with the thickness of CdTe layer varying in the range 1.50–1.80 µm. The main aim of the UPS work was to examine the position of the FL and hence to explore the doping pattern of CdTe layers during CdCl2 treatment. This information will then lead to finding the most suitable CdTe layers for fabricating CdS/CdTe thin film solar cells.

2.2 Cadmium chloride treatment

As-deposited CdTe layers were CdCl2-treated in two stages in this work, in order to investigate the trend of movement of FL in the bandgap. Saturated CdCl2 solution was diluted to 1 % using de-ionized water. In the first step, CdTe layers were dipped in this solution for 5 min, allowed to dry and then heat-treated at 440 °C for 8 min. In the second step, the same CdTe layers were treated with CdCl2 again in a similar way and heat-treated at 440 °C for 16 min. In this two-stage treatment, temperature was kept constant, but the heat treatment duration was doubled to induce changes within the material. UPS studies were carried out on as-deposited samples and on the CdCl2-treated samples already treated in the two stages mentioned above. In device processing, the CdCl2 treatment has only one stage, but this work has been carried out in two stages in order to observe the trend in FL movement during this treatment. Although not ideal, this two stage treatment was purposely selected in order to observe gradual changes in the FL position.

2.3 Photoelectrochemical cell measurements

The photoelectrochemical (PEC) cell measurements were carried out on all electrodeposited layers in order to determine their electrical conductivity type. The CdCl2 treatment was carried out in one stage, very similar to the process carried out prior to device fabrication. CdTe surfaces were treated with 1 % CdCl2 solution, dried and heat treated at 440 °C for 24 min. The PEC signal was determined by making a solid/liquid junction between CdTe and Na2S2O3 solution, and measuring the open-circuit voltage of this junction under white light illumination. After calibrating the system with known materials, PEC system is a convenient and fast method to check material’s electrical conduction type. In this work, positive PEC signal indicates p-type electrical conduction while negative PEC signal indicates n-type electrical conduction. In order to confirm electrical properties of these layers, conventional Hall Effect measurements cannot be performed due to the underlying conducting FTO layer.

2.4 Ultraviolet photoelectron spectroscopy

The UPS was used to analyze the positions of the valence band maximum (Ev) and the FL (EF). This study was conducted for four different CdTe samples. The UPS spectra were measured for as-grown films, as well as, after each of the two CdCl2 treatment steps. The measurements were performed using a VG Scientific MultiLab 3000 ultra-high vacuum surface analysis system, equipped with a CLAM4 hemispherical electron energy analyzer and a differentially-pumped He cold cathode capillary discharge UV lamp. The samples were excited with a resonance line He-I (hν = 21.22 eV) and the base chamber pressure was in the 10−9 Torr range. To shift the spectra out of nonlinear region of the analyzer and to avoid instrumental distortions/cutoffs in the lens system at low kinetic energy (c.a. <10 eV), all measurements were performed under the same negative bias of 18 V. The position of the FL was measured from the He-I Fermi edge of gold films sputtered on to half of the investigated samples. For the sputtering, each sample was covered partially with a glass slide and a thin gold layer was deposited in the exposed region. A silver paste was used to connect the sputtered gold film with the sample stage to enable its effective electrical biasing.

The UPS is a highly surface sensitive technique and the measured spectra can be affected by impurities on the surface and charging effects. The aim of this work is to study practical and real CdTe thin films used in device fabrication, with impurities such as O, excess Cd and Cl on the surface. The charging is the other effect, especially for the material layers grown on thick glass substrates. A direct method to deal with charging effects would be to use a flood gun, but this facility was not available in the UHV system used in this work. Therefore an alternative method was used by aligning the FL of CdTe with a gold film and connecting it to the sample holder. To achieve this, section of each CdTe film was sputter-coated with Au film and the gold layer was electrically connected to the sample holder with Ag conducting paste. Since the Au film and CdTe were in good electrical contact, the position of the FL, measured in the Au film, should be the same for CdTe film, which should take care of any spectrum shift caused by possible charging. The Au film, electrically connected to the sample holder, using Ag-paste provided a conducting path and avoided charging effects. Also, spectra obtained for several locations on the CdTe surface were checked to verify uniformity of UPS spectra during measurements.

3 Results and discussion

3.1 Summary of photoelectrochemical cell measurements

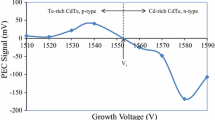

Figure 1 shows typical PEC signal versus growth voltage (Vg) for CdTe layers grown using sulphate precursor [6] and nitrate precursor [4]. In both cases, it has been observed that the material can be grown stoichiometric and with highest crystallinity at the voltage labelled Vi. At voltages below Vi, the material is rich in Te and shows p-type electrical conduction. At voltages above Vi, the material is rich in Cd and shows n-type electrical conduction. Once the materials are CdCl2-treated, it has been observed that the p-CdTe gradually changes towards n-type and n-CdTe gradually changes towards p-type. This is a startling result, indicating the FL movement across the bandgap upon CdCl2 treatment. This movement of FL shows only the variation of doping concentration, but not a complete type conversion in all cases. This trend is similar for electrodeposited CdTe layers grown using both CdSO4 (Fig. 1a) and Cd(NO3)2 (Fig. 1b) precursors. It should be noted that the defects structure and doping concentration of each layer depends on the Te-concentration in the bath, growth voltage used and the nature of the acidity (sulphuric or nitric) of the electrolyte. Therefore, the PEC signal for each sample can vary, but here we can only observe the general trends.

Typical PEC measurement results for CdTe grown using a sulphate precursor and b nitrate precursor. Note the possibility of growth of n-type and p-type CdTe layers simply by changing the stoichiometry of the materials. The CdTe layers used for UPS measurements were grown close to the stoichiometry points at Vi to obtain crystalline CdTe layers

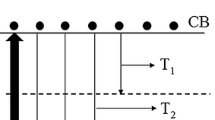

Combining the above PEC results and the other reported information in the literature [7], the possible FL movement across the bandgap is indicated in Fig. 2, for both p- and n-type CdTe layers. This diagram shows the trend of movement of FL from p towards n and from n towards p as observed using PEC measurements. Our recently reported device work [3] also indicates that the highest efficiencies are achieved when the FL settles in the shaded region just above the mid-point or intrinsic FL position. This has also been reported by Schulmeyer et al. [7] by working on Antek CdTe layers using X-ray photoelectron spectroscopy (XPS). These authors measured the position of the FL using XPS, as a function of CdCl2 treatment of Antek CdTe layers grown by close space sublimation (CSS). They have observed that the highest efficiency values are found when the FL is above the mid-point in the bandgap which says the material is n-type in electrical conduction. These results confirm that the situation is identical for both electroplated CdTe and closed space sublimated CdTe layers.

The trends of FL movement observed from PEC measurements of CdTe layers. FL of p-CdTe layers (A) move towards the conduction band and those of n-CdTe layers (C) move towards the valence band during CdCl2 treatment. For high performance solar cells the FL should settle in the shaded area around point (B) (not to scale). Possible doping concentration values are also indicated using the device measurements and the values reported for high performance cells in the literature [8–11]

Figure 2 also indicates the possible doping concentration changes assuming 1010 cm−3 for intrinsic CdTe [7]. The literature indicates that the highest CdS/CdTe solar cell efficiencies are obtained for ~ 5.0 × 1013–5.0 × 1015 cm−3 doping concentrations [8–11]. This region is shaded in Fig. 2, and therefore the growth and processing conditions should bring the FL to this shaded region in order to produce high performance solar cells.

Collection of all experimental evidence discussed above show that there exists an optimum energy range for FL to settle and produce high efficiency solar cells. This is a real challenge for solar cell developers to move the FL to this energy range and stop the processing conditions at this particular position. The UPS results presented in this paper confirm this trend and observation.

3.2 Summary of UPS results

The required UPS spectra were obtained for gold layer and four CdTe thin films in order to determine the position of the FL with respect to the band edges. For the FL determination, a He-I spectrum, as the one shown in Fig. 3a, was acquired from the gold-sputtered area. The low kinetic energy cut-off edge, (shown in detail in Fig. 3b), represents electrons ionized from the deepest valence band states accessible with the excitation energy, hν = 21.22 eV of the He-I line. At the other end of the spectrum, i.e. at the high kinetic energy end (shown in detail in Fig. 3c), the FL edge can be clearly visible, which represents electrons ionized from the states located at the FL. Because of high density of occupied states at and below the FL, the Fermi step can be clearly seen in gold and any other metallic samples. The position of the FL can be assigned at the half maximum of the step height. A different situation is in the case of semiconductor samples, where the FL is typically located within the energy band gap and even in the case of it’s pinning to a deep state level, there are typically much lower density of states and the Fermi step is hard to detect in the UPS spectrum (see Fig. 3f). Therefore, in our study, the positions of the FL in the CdTe layers were derived from the ones measured for gold films. Since the CdTe layers were in a direct contact with the sputtered gold films, the FL were assumed to equalize across the interfaces. Therefore, for the CdTe spectra, the positions of the FL were assumed to be the same as the ones measured for the gold films. The high kinetic energy part of UPS spectra measured for CdTe films showed two photoionization edges E1 and E2 as shown in Fig. 3f. In these cases, E2 represents the valence band maximum and E1 represents some defect states. By measuring the onsets of these edges (as shown in Fig. 3f for example), the valence band maximum and defect levels can be determined. The summary of these results are shown in Table 1.

Typical UPS spectra obtained for gold films and CdTe layers; a UPS spectrum obtained for gold layer, b low KE cut-off edge for gold, c high KE FL edge for gold, d a UPS spectrum obtained for as deposited CdTe layer grown from CdCl2 precursor (A1), e low KE cut-off for CdTe and f high KE cut-off (VB) edge for CdTe

It should be noted that the UPS technique was carefully selected for this project in order to understand the crucial CdCl2 processing step. Also, the aim is to study the real surfaces used for CdS/CdTe solar cell development. Although many factors affect the position of the FL, this experiment shows the surface material is either n- or p-type in electrical conduction. What is most important is the position of the FL with respect to the mid-point of the bandgap, measured with an error of ±0.05 eV.

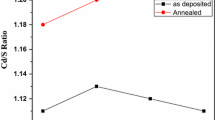

Table 1 summarises the results of UPS measurements for investigated four different CdTe layers. Band gap of CdTe has been taken as 1.44 eV for calculations of Ec–EF values. In these measurements, UPS spectra were recorded from different points in order to deal with non-uniformity issues of the layers. Non-uniformity could arise due to various factors such as non-uniform FTO thickness, variation of growth voltage (Vg) along the FTO surface due to potential drop, differences in FTO surface cleanliness and the variations created during growth and processing of these thin films. However, the technique is capable of detecting the FL position with an error of ±0.05 eV. The FL positions of the as-deposited materials are shown in Fig. 4 for easy reference. CdTe samples, S1 and S3 are n-type, and S2 and S4 are p-type in electrical conduction. FL of S2 is very close to the mid-point and therefore highly resistive close to intrinsic material. These four CdTe layers are grown from different electrolytes at different growth voltages. Table 2 summarises the electrical conduction type as determined by growth voltage and PEC measurements, and by the UPS measurements. Both measurements confirm the type of CdTe layers accurately.

Tables 3 and 4 show the UPS results obtained after two stages of CdCl2 treatment. The summary of FL positions for as-deposited layers and after CdCl2 treatment in two steps, are shown in Table 5.

The above changes are graphically shown in Fig. 5 for easy reference. The point 1 represents the as-deposited material and points 2 and 3 represent the situation after two CdCl2 treatments. S1 and S3 CdTe layers are n-type in as-grown conditions, but remain n-type after CdCl2 treatment. However, both S2 and S4 samples are p-type in as-grown conditions but become n-type after CdCl2 treatment.

UPS studies depend on the work function and the electron affinity of the layers studied. As-deposited and CdCl2 treated CdTe layers are certainly have very different properties as shown in final device performance. Although the above two parameters are important in photoemission, this subject area is out of the scope of this paper. Our current interest is only to find the position of the FL in the CdTe energy bandgap with respect to the mid-point of 0.72 eV below the conduction band.

UPS results show that both n-type samples S1 and S3 remained n-type after CdCl2 treatment. The FL tends to stay in the upper half of the bandgap. However, both p-type samples S2 and S4 changed from p-type to n-type electrical conduction. Therefore all four samples show the settling of FL in the upper half of the bandgap showing final n-type nature of the surface of CdTe layers after CdCl2 treatment.

It is clear that the native defects and impurities present in the layers are different and hence the final stage of electrical conduction after CdCl2 treatment is different from the initial stage for different samples. It is a challenging task to establish the right conditions for high efficiency devices, and therefore needs careful experimentation to achieve optimum conditions.

4 Conclusions

The results presented in this paper lead to drawing several conclusions on CdTe materials and expected device performance.

-

(a)

Electrodeposition of CdTe layers from three different precursors (sulphate, nitrate and chloride) enables the understanding of different properties of CdTe layers. Electroplating provides a convenient method to grow pre-determined n-type and p-type CdTe layers.

-

(b)

Photoelectrochemical cell method is a simple and fast technique to determine the electrical conduction type of thin film semiconducting materials, and helps to understand the CdCl2 treatment of CdTe layers.

-

(c)

Time consuming but complimentary UPS measurements confirm the electrical conduction type by measuring the position of FL within the energy bandgap. UPS helps in monitoring the FL movement during CdCl2 processing step and hence the doping concentration variation during CdCl2 treatment.

-

(d)

The combination of the knowledge of growth voltage, PEC measurements and UPS measurements enhances the understanding of material issues and development of CdTe-based thin film solar cells. UPS studies show that whatever the initial CdTe layer used in this work, the FL settles in the upper half of the bandgap after CdCl2 treatment. This is in contrast to the assumption made in the past—the type conversion from n-type to p-type after heat treatment in the presence of CdCl2.

-

(e)

The PEC and UPS results presented in this paper for electrodeposited CdTe, and XPS results published by Schulmeyer et al. for CSS grown CdTe show that the high efficiency CdS/CdTe solar cells can be achieved when n-type CdTe is used in device structures.

References

I.M. Dharmadasa, Review of the CdCl2 treatment used in CdS/CdTe thin film solar cell development and new evidence towards improved understanding. Coatings 4(2), 282–307 (2014). doi:10.3390/coatings4020282

I.M. Dharmadasa, P.A. Bingham, O.K. Echendu, H.I. Salim, T. Druffel, R. Dharmadasa, G.U. Sumanasekera, R.R. Dharmasena, M.B. Dergacheva, K.A. Mit, K.A. Urazov, L. Bowen, M. Walls, A. Abbaas, Fabrication of CdS/CdTe-based thin film solar cells using an electro-chemical technique. Coatings 4, 380–415 (2014). doi:10.3390/coatings4030380

O.K. Echendu, F. Fauzi, A.R. Weerasinghe, I.M. Dharmadasa, High short-circuit current density CdTe solar cells using all-electrodeposited semiconductors. Thin Solid Films 556, 529–534 (2014). doi:10.1016/j.tsf.2014.01.071

H.I. Salim, V. Patel, A. Abbas, M. Walls, I.M. Dharmadasa, Electrodeposition of CdTe thin film solar cells using nitrate precursor. J. Mater. Sci. Mater. Electron. (2015). doi:10.1007/s10854-015-2805-x

N.A. Abdul-Manaf, H.I. Salim, M.L. Madugu, O.I. Olusola, I.M. Dharmadasa, Electroplating and characterisation of cadmium telluride thin films using CdCl2 as the cadmium source. Energies 8(10), 10883–10903 (2015)

F. Fauzi, Research & Development of CdS/CdTe solar cells incorporating ZnTe layers, PhD Thesis, Sheffield Hallam University, 2014

T. Schulmeyer, J. Fritsche, A. Thiben, A. Klein, W. Jaegermann, M. Campo, J. Beier, Effect of in situ UHV CdCl2-activation on the electronic properties of CdTe thin film solar cells. Thin Solid Films 431–432, 84–89 (2003)

O.K. Echendu, Thin film solar cells using all-electrodeposited ZnS, CdS and CdTe materials, PhD Thesis, Sheffield Hallam University, 2014

J. Britt, C. Ferekides, Thin film CdS/CdTe solar cell with 15.8% efficiency. Appl. Phys. Lett. 62, 2851–2852 (1993)

T. Potlag, L. Ghimpu, P. Gashin, A. Pudov, T. Nagle, J. Sites, Influence of annealing in different chlorides on the photovoltaic parameters of CdS/CdTe solar cells. Sol. Energy Mater. Sol. Cells 80, 327–334 (2003)

R.G. Dhere, M. Bonnet-Eymard, E. Charlet, E. Peter, J.N. Ducnow, J.V. Li, D. Kuciauska, T.A. Gessert, CdTe solar cell with industrial Al:ZnO on soda-lime glass. Thin Solid Films 519, 7142–7145 (2011)

M.P. Seah, W.A. Dench, Quantitative electron spectroscopy of surfaces: a standard data base for electron inelastic mean free paths in solids. Surf. Interface Anal. 1(1), 2–11 (1979)

Acknowledgments

The authors would like to acknowledge the contributions made to this work by Thad Druffle, Ruvini Dharmadasa, Brandon Lavery, Olajide Olusola, Mohammad Madugu, Ayotunde Ojo and Paul Bingham.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Dharmadasa, I.M., Echendu, O.K., Fauzi, F. et al. Study of Fermi level position before and after CdCl2 treatment of CdTe thin films using ultraviolet photoelectron spectroscopy. J Mater Sci: Mater Electron 27, 5039–5046 (2016). https://doi.org/10.1007/s10854-016-4391-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4391-y