Abstract

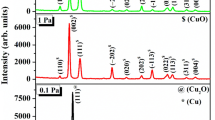

Copper oxide (Cu2O) thin films are prepared by pulsed laser deposition (PLD) technique at different oxygen pressure (PO2). The structural, morphological, optical and electrical properties of the grown thin films are investigated systematically. XRD pattern indicates the polycrystalline nature and pure Cu2O phase thin films. The crystallinity and grain size are found to be improved with oxygen gas pressure (PO2). AFM and FESEM analysis described the dense and crystalline morphologies with minimal film roughness. AFM analysis illustrates the increased mean height and the average parameter of the grain with PO2. UV–visible optical spectra has shown large absorption (% A) of light with an apparent shift in the optical band gap from 2.56 to 2.5 eV with an increase in PO2. The thin films are quite transparent in the visible region above 500 nm. The room temperature electrical resistivity of the films is of the order of ~103 Ω-cm. The crystallography, density of defects and the energy gap appraise the film resistivity. The p-type conductivity of Cu2O is related to the presence of Cu-vacancies. The obtained activation energy and current–voltage (I–V) properties, highlight the potential applications of Cu2O films.

Similar content being viewed by others

References

D.P. Norton, Mat. Sci. Eng. R 43, 139 (2004)

Z.Q. Yao, S.L. Liu, L. Zhang, B. He, A. Kumar, X. Jiang, W.J. Zhang, G. Shao, Appl. Phys. Lett. 101, 042114 (2012)

A. Chen, H. Long, X. Li, Y. Li, G. Yang, P. Lu, Vacuum 83, 927 (2009)

L. De Los Santos Valladares, D.H. Salinas, A.B. Dominguez, D.A. Najarro, S.I. Khondaker, T. Mitrelias, C.H.W. Barnes, J.A. Aguiar, Y. Majima, Thin Solid Films 520, 6368 (2012)

F.A. Akgul, G. Akgul, N. Yildirim, H.E. Unalan, R. Turan, Mater. Chem. Phys. 147, 987 (2014)

L. Zhang, L. McMillon, J. McNatt, Sol. Energy Mat. Sol. C. 108, 230 (2013)

J. Deuermeier, J. Gassmann, J. Brotz, A. Klein, J. Appl. Phys. 109, 113704 (2011)

R.P. Wijesundera, Semicond. Sci. Technol. 25, 045015 (2010)

C.C. Tseng, J.H. Hsieh, W. Wu, Thin Solid Films 519, 5169 (2011)

G. Guerguerian, F. Elhordoy, C.J. Pereyra, R.E. Marotti, F. Martin, D. Leinen, J.R. Ramos-Barrado, E.A. Dalchiele, J. Phys. D Appl. Phys. 45, 245301 (2012)

D.S. Darvish, H.A. Atwater, J. Cryst. Growth 319, 39 (2011)

A. Karapetyan, A. Reymers, S. Giorgio, C. Fauquet, L. Sajti, S. Nitsche, M. Nersesyan, V. Gevorgyan, W. Marine, J. Lumin. 159, 325 (2015)

H. Raebiger, S. Lany, A. Zunger, Phys. Rev. B 76(325), 045209 (2007)

Z. Rosenstock, I. Feldman, I. Riess, Solid State Ionics 175, 375 (2004)

S. Laidoudi, A.Y. Bioud, A. Azizi, G. Schmerber, J. Bartringer, S. Barre, A. Dinia, Semicond. Sci. Technol. 28, 115005 (2013)

Y. Nishi, T. Miyata, T. Minami, Thin Solid Films 528, 72 (2013)

T. Serin, S. Gurakar, N. Serin, N. Yildirim, F. Ozyurt Kus, J. Phys. D Appl. Phys. 42, 225108 (2009)

F. Pei, S. Wu, G. Wang, M. Xu, S.Y. Wang, L.Y. Chen, Y. Jia, J. Korean Phys. Soc. 55, 1243 (2009)

L. Schramm, G. Behr, W. Loser, K. Wetzig, J. Phase Equilib. Diff. 26, 605 (2005)

B.D. Cullity, S.R. Stock, Elements of X-ray diffraction, 3rd edn. (Prentice-Hall, New Jersey, 2001), p. 89, 42

D. Brandon, W.D. Kaplan, Microstructural characterization of materials, 2nd edn. (Wiley, Sussex, 2008), pp. 63–90

H. Nagai, T. Suzuki, H. Hara, C. Mochizuki, I. Takano, T. Honda, M. Sato, Mater. Chem. Phys. 137, 252 (2012)

P.J. Goodhew, J. Humphreys, R. Beanland, Electron microscopy and analysis, 3rd edn. (Taylor and Francis, London and New York, 2001), p. 46

H.-S. Zhang, J.L. Endrino, A. Anders, Appl. Surf. Sci. 255, 2551 (2008)

R. Swanepoel, J. Phys. E Sci. Instrum. 16, 1214 (1983)

B. Balamurugan, B.R. Mehta, Thin Solid Films 396, 90 (2001)

J.P. Hu, D.J. Payne, R.G. Egdell, P.A. Glans, T. Learmonth, K.E. Smith, Phys. Rev. B 77, 155115 (2008)

D.K. Schroder, Semiconductor material and device characterization, 3rd edn. (Wiley, Canada, 2006), p. 10

T. Mahalingam, J.S.P. Chitra, J.P. Chu, H. Moon, H.J. Kwon, Y.D. Kim, J. Mater. Sci. Mater. Electron. 17, 519 (2006)

Acknowledgments

The author gratefully acknowledges the Department of Science and Technology for their financial support of INSPIRE fellowship for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kaur, G., Mitra, A. & Yadav, K.L. Influence of oxygen pressure on the growth and physical properties of pulsed laser deposited Cu2O thin films. J Mater Sci: Mater Electron 26, 9689–9699 (2015). https://doi.org/10.1007/s10854-015-3636-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3636-5