Abstract

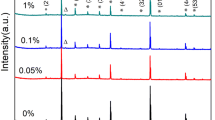

CaCu3Ti4O12 (CCTO) particles were prepared separately by the sol–gel method (sg) and solid-state method (ss). CCTO-sg particles were more uniform, narrower distribution size and smaller (effective diameter of 290 nm) than that of CCTO-ss particles with the value of 480 nm for CCTO-ss particles. The CCTO-sg particles exhibited a small particle size and in turn improved chemical activity and lower crystallization temperature, which give rise to the enhanced dielectric properties. CCTO-sg and CCTO-ss filled polyvinylidene fluoride (CCTO/PVDF) were molded by solution mixing process and hot-pressing. The enhanced dielectric constant, good frequency and temperature stability of CCTO/PVDF composites were significant with increasing the volume fraction of CCTO particles. Compared to two kinds of composites, the CCTO-sg/PVDF composites exhibited better dielectric properties than CCTO-ss/PVDF composites. The dielectric constant of 50 vol% CCTO-sg/PVDF composites reached the maximum value of 62.3, which was 8 times and 2 times larger than that of pure PVDF and 50 vol%CCTO-ss/PVDF composites, respectively. The temperature coefficient \(\left( {\frac{{C_{T} - C_{25^\circ C} }}{{C_{25^\circ C} }} \times 100\;\% } \right)\) of CCTO-sg/PVDF composites was −3 to 10 % from −10 to 150 °C at 10 kHz, which was lower than that of CCTO-ss/PVDF composites. Meanwhile, the dielectric constant of CCTO/PVDF obtained by Maxwell–Garnett model and Yamada model were in close agreement with the experimental data, respectively.

Similar content being viewed by others

References

M. Arbatti, X.B. Shan, Z.Y. Cheng, Adv. Mater. 19, 1369 (2007)

M. Kakimoto, A. Takahashi, T. Tsurumi, J. Hao, L. Li, R. Kikuchi, T. Miwa, T. Oono, S. Yamad, Mater. Sci. Eng. B 132, 74 (2006)

J.H. Yu, D.A. Chestakov, H.J. Eggink, Microelectron. J. 44, 1025 (2013)

X. Su, M. Tomozawa, J.K. Nelson, D.B. Chrisey, J. Mater. Sci. Mater. Electron. 24, 2135 (2013)

L. Zhang, Z.Y. Cheng, J. Adv. Dielectr. 1, 389 (2011)

Q.M. Zhang, H.F. Li, M. Poh, F. Xia, Z.Y. Cheng, H.S. Xu, C. Huang, Nature 419, 284 (2002)

A.K. Yadav, C. Gautam, J. Mater. Sci. Mater. Electron. 25, 5165 (2014)

M.H. Chen, J.H. Yin, X.X. Liu, Y. Feng, B. Su, Q.Q. Lei, Thin Solid Films 544, 116 (2013)

L. Zhang, X.B. Shan, P.X. Wu, Z.Y. Cheng, Appl. Phys. A 107, 597 (2012)

F.J. Wang, W. Li, M.S. Xue, J.P. Yao, J.S. Lu, Compos. Part B. 42, 87 (2011)

Y. Kobayashi, T. Tanasea, T. Tabata, T. Miwa, M. Konno, J. Eur. Ceram. Soc. 28, 117 (2008)

A.K. Zak, W.C. Gan, W.H.A. Majid, M. Darroudi, T.S. Velayutham, Ceram. Int. 37, 1653 (2011)

V. Pascariu, L. Padurariu, O. Avadanei, L. Mitoseriu, J. Alloys Compd. 574, 591 (2013)

Y. Bai, Z.Y. Cheng, V. Bharti, H.S. Xu, Q.M. Zhang, Appl. Phys. Lett. 76, 3804 (2000)

S.U. Adikary, H.L.W. Chan, C.L. Choy, B. Sundaravel, I.H. Wilson, Compos. Sci. Technol. 62, 2161 (2002)

R.K. Goyal, S.S. Katkade, D.M. Mule, Compos. Part B 44, 128 (2013)

Y.P. Shen, A.J. Gu, G.Z. Liang, L. Yuan, Compos. Part A 41, 1668 (2010)

Fajun Wang, Dongxiang Zhou, Yunxiang Hu, Phys. Status Solidi A 206, 2632–2636 (2009)

Z.M. Dang, T. Zhou, S.H. Yao, Adv. Mater. 21, 2077 (2009)

D.L. Sun, A.Y. Wu, S.T. Yin, J. Am. Ceram. Soc. 91, 1404 (2008)

W.Q. Ni, X.H. Zheng, J.C. Yu, J. Mater. Sci. 42, 1037 (2007)

N.L. An, H.Z. Liu, Y.C. Ding, M. Zhang, Appl. Surf. Sci. 257, 3831 (2011)

M.P. Silva, V. Sencadas, G. Botelho, A.V. Machado, A.G. Rolo, J.G. Rocha, S. Lanceros-Mendez, Mater. Chem. Phys. 122, 87 (2010)

J.C. Zhao, J. Liu, G. Ma, Ceram. Int. 38, 1221 (2012)

C. Yang, H.S. Song, D.B. Liu, Compos. Part B-Eng. 50, 180 (2013)

M. Li, Z.J. Shen, M. Nygren, A. Feteira, D.C. Sinclair, A.R. West, J. Appl. Phys. 106, 104106 (2009)

Y. Yang, B.P. Zhu, Z.H. Lu, Z.Y. Wang, C.L. Fei, Appl. Phys. Lett. 102, 042904 (2013)

R.E. Newnham, D.P. Skinner, L.E. Cross, Mater. Res. Bull. 13, 525 (1978)

Z.M. Dang, Y.Q. Lin, H.P. Xu, C.Y. Shi, S.T. Li, J.B. Bai, Adv. Funct. Mater. 18, 1509 (2008)

Acknowledgments

This work was supported by National Science Foundation of China (NSFC) (Grant Nos. 51172136 and 51107077), and the Fundamental Research Funds for the Central Universities (Program Nos. GK201301002, GK201305013 and GK201403006) and Science and Technology Program of Shaanxi Province and Xi’an City (Grant Nos. 2013K09-26 and CXY1342(4)).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chao, X., Wu, P., Zhao, Y. et al. Effect of CaCu3Ti4O12 powders prepared by the different synthetic methods on dielectric properties of CaCu3Ti4O12/polyvinylidene fluoride composites. J Mater Sci: Mater Electron 26, 3044–3051 (2015). https://doi.org/10.1007/s10854-015-2795-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2795-8