Abstract

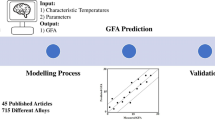

The prediction accuracy of current mainstream machine learning (ML) models depends on regulating many hyperparameters. In this paper, a deep forest (DF) model with a few hyperparameters and a non-excessive dependence on super parameter regulation was applied to the prediction of glass-forming ability (GFA) of bulk metallic glasses (BMGs). Compared with these of the mainstream ML models, including Support Vector Regression (SVR), random forest (RF), gradient boosted decision trees (GBDT), k-nearest neighbor (KNN), and eXtreme gradient boosting (XGBoost), the tenfold cross-validation shows that the determination coefficient (R2) of our suggested DF model is improved by 10.4%–74.2%. Moreover, the parameter \(\Phi\) obtained by the SHapley Additive exPlanations (SHAP) method analysis can be used to guide the design and development of BMGs. Finally, a design and development of scheme process for BMGs that meets the expected requirements is given via parameter \(\Phi\) and the constructed DF model.

Similar content being viewed by others

Data availability

I have shared my data in Supplementary Material.

References

Jiang H, Wei X, Lu W et al (2019) Design of Cu-Zr-Al and Cu-Zr-Al-Sn bulk amorphous alloys with high glass-forming ability. J Non Cryst Solids 521:119531. https://doi.org/10.1016/j.jnoncrysol.2019.119531

Li MX, Zhao SF, Lu Z et al (2019) High-temperature bulk metallic glasses developed by combinatorial methods. Nature 569(7754):99–103. https://doi.org/10.1038/s41586-019-1145-z

Park JS, Lim HK, Kim JH et al (2005) Shear band formation and mechanical properties of cold-rolled bulk metallic glass and metallic glass matrix composite. J Mater Sci 40:1937–1941. https://doi.org/10.1007/s10853-005-1214-6

Bordeenithikasem P, Liu J, Kube SA et al (2017) Determination of critical cooling rates in metallic glass forming alloy libraries through laser spike annealing. Sci Rep 7(1):1–9. https://doi.org/10.1038/s41598-017-07719-2

Byrne CJ, Eldrup M (2008) Bulk metallic glasses. Science 321(5888):502–503. https://doi.org/10.1126/science.1158864

Lu ZP, Tan H, Li Y et al (2000) The correlation between reduced glass transition temperature and glass-forming ability of bulk metallic glasses. Scr Mater 42:667–673. https://doi.org/10.1016/S1359-6462(99)00417-0

Lu ZP, Liu CT (2002) A new glass-forming ability criterion for bulk metallic glasses. Acta Mater 50:3501–3512. https://doi.org/10.1016/S1359-6454(02)00166-0

Xiao XS, Fang SS, Wang GM, Hua Q, Dong YD (2004) Influence of beryllium on thermal stability and glass-forming ability of Zr-Al-Ni-Cu bulk amorphous alloys. J Alloys Compd 376:145–148. https://doi.org/10.1016/j.jallcom.2004.01.014

Mongal K, Murty BS (2005) On the parameters to assess the glass forming ability of liquids. J Non-Cryst Solids 351:1366–1371. https://doi.org/10.1016/j.jnoncrysol.2005.03.006

Chen QJ, Shen J, Zhang DL, Fan HB, Sun JF, Mccartney DG (2006) A new criterion for evaluating the glass-forming ability of bulk metallic glasses. Mater Sci Eng A 433:155–160. https://doi.org/10.1016/j.msea.2006.06.053

Du XH, Huang JC, Liu CT, Lu ZP (2007) New criterion of glass forming ability for bulk metallic glasses. J Appl Phys 101(8):086108. https://doi.org/10.1063/1.2718286

Fan GJ, Choo H, Liaw PK (2007) A new criterion for the glass-forming ability of liquids. J Non-Cryst Solids 353(1):102–107. https://doi.org/10.1016/j.jnoncrysol.2006.08.049

Du XH, Huang JC (2008) New criterion in predicting glass forming ability of various glass-forming systems. Chinese Phys B 17(1):249–254. https://doi.org/10.3321/j.issn:1674-1056.2008.01.043

Yuan ZZ, Bao SL, Lu Y, Zhang DP, Yao L (2008) A new criterion for evaluating the glass-forming ability of bulk glass forming alloys. J Alloys Compd 459(1–2):251–260. https://doi.org/10.1016/j.jallcom.2007.05.037

Long ZL, Wei HQ, Ding YH, Zhang P, Xie GQ, Inoue A (2009) A new criterion for predicting the glass-forming ability of bulk metallic glasses. J Alloys Compd 475(1–2):207–219. https://doi.org/10.1016/j.jallcom.2008.07.087

Ji XL, Pan Y (2009) A thermodynamic approach to assess glass-forming ability of bulk metallic glasses. T Nonferr Metal SOC 19(05):1271–1279. https://doi.org/10.1016/S1003-6326(08)60438-0

Zhang GH, Chou KC (2009) A criterion for evaluating glass-forming ability of alloys. J Appl Phys 106(9):094902. https://doi.org/10.1063/1.3255952

Guo S, Liu CT (2010) New glass forming ability criterion derived from cooling consideration. Intermetallics 18(11):2065–2068. https://doi.org/10.1016/j.intermet.2010.06.012

Dong BS, Zhou SX, Li DR, Lu CW, Guo F, Ni XJ, Lu ZC (2011) A new criterion for predicting glass forming ability of bulk metallic glasses and some critical discussions. Prog Nat Sci Mater Int 21(02):164–172. https://doi.org/10.1016/S1002-0071(12)60051-3

Blyskun P, Maj P, Kowalczyk M, Latuch J, Kulik T (2015) Relation of various GFA indicators to the critical diameter of Zr-based BMGs. J Alloys Compd 625:13–17. https://doi.org/10.1016/j.jallcom.2014.11.112

Long ZL, Liu W, Zhong M, Zhang Y, Zhao MSZ, Liao GK, Chen Z (2018) A new correlation between the characteristic temperature and glassforming ability for bulk metallic glasses. J Therm Anal Calorim 132(3):1645–1660. https://doi.org/10.1007/s10973-018-7050-0

Deng RJ, Long ZL, Peng L, Kuang DM, Ren BY (2020) A new mathematical expression for the relation between characteristic temperature and glass-forming ability of metallic glasses. J Non-Cryst Solids 533:119829. https://doi.org/10.1016/j.jnoncrysol.2019.119829

Butler KT, Davies DW, Cartwright H, Isayev O, Walsh A (2018) Machine learning for molecular and materials science. Nature 559(7715):547–555. https://doi.org/10.1038/s41586-018-0337-2

Sun YT, Bai HY, Li MZ, Wang WH (2017) Machine learning approach for prediction and understanding of glass-forming ability. J Phys Chem Lett 8(14):3434–3439. https://doi.org/10.1021/acs.jpclett.7b01046

Ward L, O’Keeffe SC, Stevick J, Jelbert GR, Aykol M, Wolverton C (2018) A machine learning approach for engineering bulk metallic glass alloys. Acta Mater 159:102–111. https://doi.org/10.1016/j.actamat.2018.08.002

Liu X, Li X, He Q, Liang D, Zhou Z, Ma J, Yang Y, Shen J (2020) Machine learning based glass formation prediction in multicomponent alloys. Acta Mater 201:182–190. https://doi.org/10.1016/j.actamat.2020.09.081

Deng BH, Zhang YL (2020) Critical feature space for predicting the glass forming ability of metallic alloys revealed by machine learning. Chem Phys 538:110898. https://doi.org/10.1016/j.chemphys.2020.110898

Xiong J, Shi SQ, Zhang TY (2020) A machine-learning approach to predicting and understanding the properties of amorphous metallic alloys. Mater Des 187:108378. https://doi.org/10.1016/j.matdes.2019.108378

Ren BY, Long ZL, Deng RJ (2021) A new criterion for predicting the glass-forming ability of alloys based on machine learning. Comput Mater Sci 189:110259. https://doi.org/10.1016/j.commatsci.2020.110259

Liu X, Long Z, Yang L, Zhang W, Li Z (2021) Prediction of glass forming ability in amorphous alloys based on different machine learning algorithms. J Non-Cryst Solids 570:121000. https://doi.org/10.1016/j.jnoncrysol.2021.121000

Peng L, Long Z, Zhao M (2021) Determination of glass forming ability of bulk metallic glasses based on machine learning. Comput Mater Sci 195:110480. https://doi.org/10.1016/j.commatsci.2021.110480

Reddy GJ, Kandavalli M, Saboo T, Rao AK (2021) Prediction of Glass Forming Ability of Bulk Metallic Glasses Using Machine Learning. Integr Mater Manuf Innov 10(4):610–626. https://doi.org/10.1007/s40192-021-00239-y

Li Z, Long Z, Lei S, Zhang T, Liu X, Kuang D (2021) Predicting the glass formation of metallic glasses using machine learning approaches. Comput Mater Sci 197:110656. https://doi.org/10.1016/j.commatsci.2021.110656

Zhang YX, Xing GC, Sha ZD, Poh LH (2021) A two-step fused machine learning approach for the prediction of glass-forming ability of metallic glasses. J Alloys Compd 875:160040. https://doi.org/10.1016/j.jallcom.2021.160040

Yao Y, Sullivan T IV, Yan F, Gong J, Li L (2022) Balancing data for generalizable machine learning to predict glass-forming ability of ternary alloys. Scr Mater 209:114366. https://doi.org/10.1016/j.scriptamat.2021.114366

Liu XW, Long ZL, Zhang W, Yang LM (2022) Key feature space for predicting the glass-forming ability of amorphous alloys revealed by gradient boosted decision trees model. J Alloys Compd 901:163606. https://doi.org/10.1016/j.jallcom.2021.163606

Wilkinson CJ, Trivelpiece C, Hust R, Welch RS, Feller SA, Mauro JC (2022) Hybrid machine learning/physics-based approach for predicting oxide glass-forming ability. Acta Mater 222:117432. https://doi.org/10.1016/j.actamat.2021.117432

Zhou ZH, Feng J (2017) Deep forest: towards an alternative to deep neural networks, In: Proceedings of the 26th International joint conference on artificial intelligence (IJCAI’17), AAAI press, Melbourne, Australia pp. 3553–3559. http://arxiv.org/abs/1702.08835

Zhou ZH, Feng J (2019) Deep forest Natl Sci Rev 6(01):74–86. https://doi.org/10.1093/nsr/nwy108

Tian X, Shen L, Wang Z, Zhou L, Peng L (2021) A novel lncRNA–protein interaction prediction method based on deep forest with cascade forest structure. Sci Rep 11:1–15. https://doi.org/10.1038/s41598-021-98277-1

Yu B, Chen C, Wang X, Yu Z, Ma A, Liu B (2021) Prediction of protein–protein interactions based on elastic net and deep forest. Expert Syst Appl 176:114876. https://doi.org/10.1016/j.eswa.2021.114876

Yin L, Sun Z, Gao F, Liu H (2020) Deep forest regression for short-term load forecasting of power systems. IEEE Acc 8:49090–49099. https://doi.org/10.1109/ACCESS.2020.2979686

Zhou T, Sun X, Xia X, Li B, Chen X (2019) Improving defect prediction with deep forest. Inf Softw Technol 114:204–216. https://doi.org/10.1016/j.infsof.2019.07.003

Xiong J, Zhang TY (2022) Data-driven glass-forming ability criterion for bulk amorphous metals with data augmentation. J Mater Sci Technol 121(26):99–104. https://doi.org/10.1016/j.jmst.2021.12.056

Lundberg SM, Lee SI (2017) A unified approach to interpreting model predictions. Adv Neural Inform Proc Syst 30:4768–4777

Yang G, Lian J, Wang R, Wu N (2019) Similar atom substitution effect on the glass forming ability in (La-Ce)-Al-(Ni-Co) bulk metallic glasses using electron structure guiding. J Alloys Compd 786:250–256. https://doi.org/10.1016/j.jallcom.2019.01.339

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant No. 51971188).

Author information

Authors and Affiliations

Contributions

TL was responsible for conceptualization, visualization, investigation, data curation, formal analysis, and writing and preparing the original draft. ZL was responsible for conceptualization and writing—review, editing, and supervision. ZP was responsible for writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Ghanshyam Pilania.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Long, T., Long, Z. & Peng, Z. Rational design and glass-forming ability prediction of bulk metallic glasses via interpretable machine learning. J Mater Sci 58, 8833–8844 (2023). https://doi.org/10.1007/s10853-023-08528-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08528-x