Abstract

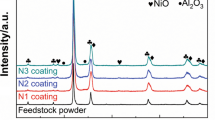

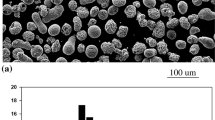

Tribaloys are Cobalt-based alloys with general composition M–Mo–Cr–Si (M = Co), with a microstructure of Laves intermetallic phases dispersed in a Co solid solution. The chemical composition plays a major role in volume fractions of the strengthening phases in these alloys, which in turn dictate the mechanical properties and tribological performance of these materials. In this study, two Co-based Tribaloy powders, i.e., Co-28.5Mo-17.5Cr-3.4Si and Co-28.5Mo-8.5Cr-2.6Si, were coated on mild steel substrate by high-velocity oxygen fuel (HVOF) spraying. Microstructure and distribution of Laves phases were studied using scanning electron microscopy (SEM) equipped with energy-dispersive X-ray (EDX) analysis as well as electron channeling contrast imaging (ECCI). Detailed phase analysis of powders and coatings was performed using X-ray diffraction (XRD). Electron backscatter diffraction (EBSD) was conducted on sprayed coatings to reveal the distribution of phases in coatings. Co3Mo2Si and Co3Mo were found to be the main constituent of intermetallic Laves phases in HVOF-sprayed coatings. A significantly lower volume fraction of Laves phases was identified in both coatings as compared to similar alloys in the literature, due to an extremely high cooling rate and solidification in HVOF. The Laves-free solid solution featured nano-crystalline microstructure with a similar local hardness to those of Laves phases. Highly flattened splats that contained nano-crystalline supersaturated solid solution displayed weak interfaces within the microstructure where cracks initiated and propagated along boundaries during splat cohesion testing.

Similar content being viewed by others

References

Wielage B, Wank A, Pokhmurska H, Grund T, Rupprecht C, Reisel G, Friesen E (2006) Development and trends in HVOF spraying technology. Surf Coat Technol 201:2032–2037

Schmidt RD, Ferriss DP (1975) New materials resistant to wear and corrosion to 1000°C. Wear 32:279–289

Sahraoui T, Fenineche NE, Montavon G, Coddet C (2004) Alternative to chromium: characteristics and wear behavior of HVOF coatings for gas turbine shafts repair (heavy-duty). J Mater Process Technol 152:43–55

Sahraoui T, Faraoun HI, Fenineche NE, Montavon G, Aourag H, Coddet C (2004) HVOF-sprayed Tribaloy©-400: microstructure and first principle calculations. Mater Lett 58:2433–2436

Navas C, Cadenas M, Cuetos JM, de Damborenea J (2006) Microstructure and sliding wear behaviour of Tribaloy T-800 coatings deposited by laser cladding. Wear 260(7):838–846

Tobar MJ, Amado JM, Álvarez C, García A, Varela A, Yáñez A (2008) Characteristics of Tribaloy T-800 and T-900 coatings on steel substrates by laser cladding. Surf Coat Technol 202(11):2297–2301

Przybylowicz J, Kusinski J (2000) Laser cladding and erosive wear of Co–Mo–Cr–Si coatings. Surf Coat Technol 125(1):13–18

Díaz E, Amado JM, Montero J, Tobar MJ, Yáñez A (2012) Comparative study of Co-based alloys in repairing low Cr-Mo steel components by laser cladding. Phys Proc 39:368–375

Ya W, Pathiraj B, Matthews DTA, Bright M, Melzer S (2018) Cladding of Tribaloy T400 on steel substrates using a high power Nd:YAG laser. Surf Coat Technol 350:323–333

Bolelli G, Cannillo V, Lusvarghi L, Montorsi M, Mantini FP, Barletta M (2007) Microstructural and tribological comparison of HVOF-sprayed and post-treated M-Mo–Cr–Si (M=Co, Ni) alloy coatings. Wear 263(7):1397–1416

Singh S, Guo Y, Winiarski B, Burnett TL, Withers PJ, De Graef M (2018) High resolution low kV EBSD of heavily deformed and nanocrystalline Aluminium by dictionary-based indexing. Sci Rep 8(1):10991

Edwards TEJ, Di Gioacchino F, Muñoz-Moreno R, Clegg WJ (2017) The interaction of borides and longitudinal twinning in polycrystalline TiAl alloys. Acta Mater 140:305–316

Zhu C, Kaufmann K, Vecchio KS (2020) Novel remapping approach for HR-EBSD based on demons registration. Ultramicroscopy 208:112851

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J Mater Res 7(6):1564–1583

Fischer-Cripps AC (2002) Nanoindentation. Springer, Mechanical engineering series

Hysitron TI 950 Triboindenter User Manual Revision 9.3.0314 Hysitron Incorporated 2014.

Vencl A, Arostegui S, Favaro G, Zivic F, Mrdak M, Mitrović S, Popovic V (2011) Evaluation of adhesion/cohesion bond strength of the thick plasma spray coatings by scratch testing on coatings cross-sections. Tribol Int 44(11):1281–1288

ISO27307:2015, Thermal spraying—Evaluation of adhesion/cohesion of thermal sprayed ceramic coatings by transverse scratch testing. Geneva, Switzerland, 2015.

Boulnat X, Lafont C, Coudert JB, Dayot C (2020) Microstructure evolution of fine-grained cobalt T400 Tribaloy processed by Spark Plasma Sintering or Hot Isostatic pressing of gas-atomized powders. Metall and Mater Trans A 51(10):5318–5327

Halstead A, Rawlings RD (1984) Structure and hardness of Co–Mo–Cr–Si wear resistant alloys (Tribaloys). Metal Sci 18(10):491–500

Mason SE, Rawlings RD (1994) Effect of iron additions on microstructure and mechanical properties of Ni–Cr–Mo–Si hardfacing alloy. Mater Sci Technol 10(10):924–928

Prior DJ, Wheeler J, Peruzzo L, Spiess R, Storey C (2002) Some garnet microstructures: an illustration of the potential of orientation maps and misorientation analysis in microstructural studies. J Struct Geol 24(6):999–1011

Bolelli G, Cannillo V, Lusvarghi L, Riccò S (2006) Mechanical and tribological properties of electrolytic hard chrome and HVOF-sprayed coatings. Surf Coat Technol 200(9):2995–3009

Yang W-J, Zou L, Cao X-Y, Liu J-H, Li D-J, Cai Z-B (2019) Fretting wear properties of HVOF-sprayed CoMoCrSi coatings with different spraying parameters. Surf Coat Technol 358:994–1005

Cho JY, Zhang SH, Cho TY, Yoon JH, Joo YK, Hur SK (2009) The processing optimization and property evaluations of HVOF Co-base alloy T800 coating. J Mater Sci 44(23):6348–6355

Bull SJ (1999) Can scratch testing be used as a model for the abrasive wear of hard coatings. Wear 233:412–423

Vencl A, Gligorijevi B, Katavi B, Nedi B, Eũni D (2013) In: Abrasive wear resistance of the iron- and WC-based hardfaced coatings evaluated with scratch test method, 2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

A. Alidokht, S., Gao, Y., de Castilho, B.C.N.M. et al. Microstructure and mechanical properties of Tribaloy coatings deposited by high-velocity oxygen fuel. J Mater Sci 57, 20056–20068 (2022). https://doi.org/10.1007/s10853-022-07843-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07843-z