Abstract

It was observed for the first time that the specific surface area of graphitic carbon nitride (g-C3N4) increased from 32 m2g−1 to 142 and 171 m2g−1 for Pt and Ru, respectively, due to the etching of g-C3N4 by Pt and Ru nanoparticles. Metal nanoparticles catalyze hydrogenation of C – N bonds and “move” through the structure of g-C3N4 etching tunnels in it and creating “spongy graphitic carbon nitride” (sgCN). The reactions take place on the surface of metal NPs, which are covered with oxidized forms of Pt and Ru capable of strong interactions with nitrogen, which was confirmed by XPS studies. The activation energy of hydrogenation of g-C3N4 is 112 and 151 kJmol−1 for Ru and Pt nanoparticles, respectively. The process of etching of g-C3N4 was observed by mass spectrometry and temperature programmed reduction coupled with on-line infrared spectroscopy. On the basis of thermodynamic considerations and quantum mechanical calculations of bonds strengths, a probable mechanism of g-C3N4 hydrogenation was proposed.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Liu and Cohen [1] predicted that carbon nitride may show very promising properties as a superhard material—harder than diamond. Then, in 2009 Wang et al. discovered some unusual photocatalytic properties of graphitic carbon nitride (g-C3N4) [2]. Graphitic carbon nitride is a layered material—just like graphite. The layers are created by tri-s-triazine (heptazine) units connected through a tertiary nitrogen atom; layers between each other are connected by hydrogen bonds [3]. Because of its layered structure, g-C3N4 can be subject to delamination/exfoliation (just like graphite). Owing to this, its specific surface area (SSA) can be increased. Using traditional methods of synthesis by thermal condensation of urea, thiourea, dicyandiamide or melamine, the specific surface area of g-C3N4 is 10–30 m2g−1 [4,5,6]. The limitation of carbon nitride is just its low SSA. In a number of potential applications such as photo-, electro-, heterogeneous- catalysis, and gas storage, a high SSA is essential. Hence, attempts were made to synthesize the high-surface area of g-C3N4 by using hard or soft template methods [7,8,9,10], by exfoliation into nanosheets [11,12,13,14] or by heteroatom doping [15, 16]. The most commonly used method is the hard template method based on the use of high-surface area inorganic material, which acts as the matrix on which g-C3N4 is synthesized. After removing the matrix, a negative copy of the used matrix is obtained. Goettmann et al. [7] obtained mesoporous g-C3N4 with a surface reaching 440 m2g−1 by using colloidal silica nanoparticles as a template. Using SBA-15, g-C3N4 was obtained with ordered, 2D hexagonal porosity and SSA reaching 239 m2g−1 [8]. Similar effects are observed by the soft template method—carbon nitrides obtained by this method reach SSA of 134 m2g−1 [9] or 220 m2g−1 [10]. Using the layered structure of carbon nitride and experience in exfoliation of graphite to graphene, g-C3N4 was subjected to similar treatments many times. For instance, exfoliation in concentrated sulfuric acid under ultrasonication allowed Lee et al. [11] for an increase in SSA of g-C3N4 from 20 to 140 m2g−1 while Gao et al. [14] to 199 m2g−1. Apart from chemical methods of exfoliation, thermal exfoliation is also applied. It allows for an increase in SSA of g-C3N4 to 150 m2g−1 [13] and sometimes even (repeating exfoliation three times) to 513 m2g−1 [12]. However, it should be pointed out that the final product yield did not exceed 6% in the latter case. The third group of methods used to increase SSA is doping of g-C3N4 by heteroatom. Zhu et al. [15] obtained phosphorus-doped graphitic carbon nitride nanostructured flowers of in-plane mesopores with surface of 83 m2g−1. Sometimes combining several methods described above gives excellent results. Thus, Zhao et al. [17] applying SBA-15 as hard template and hexamethylenetetramine as carbon nitride precursor obtained highly ordered mesoporous carbon nitride nanorods with 971–1124 m2g−1 of superhigh specific surface area.

The methods discussed above are usually laborious, often expensive and ineffective; therefore, alternative methods are still being sought.

In the 1970s, Tomita et al. [18, 19] carried out research on the hydrogenation of carbons and discovered that metal nanoparticles etch the channels on the surface of graphite [20]. Later, this phenomenon was observed many times for a few layers of graphene on a number of metals, such as Ni, Co, Fe, Ag, and W [21,22,23,24,25,26,27,28,29]. It turns out that nanoparticles of Ni etched not only the surface of highly oriented pyrolytic graphite, but also the network of tunnels throughout its volume, generating a porous form of graphite [26]. Thus, it is possible to transform non-porous (or low-porous) material into mesoporous material that consists of cylindrical pores. The only alternative to this method is the nanocasting method, which leads to mesoporous g-C3N4 too, but by its nature is time consuming and laborious, and usually requires expensive templates [17, 30,31,32].

In this work, the phenomenon of etching channels by metal nanoparticles was applied to create pores in the structure of g-C3N4 and increase its SSA. Since the etching of carbon materials is based on a hydrogenation process, platinum and ruthenium were chosen as metals of high hydrogenation activity.

Experimental

Materials and methods

Graphitic carbon nitride (g-C3N4) was obtained by pyrolysis of dicyandiamide (DCDA) (Sigma-Aldrich, 99%). 4 g of DCDA was placed in a 50 mL quartz crucible, covered with a lid, and heated in a muffle furnace for 4 h at the temperature of 600 °C (heating rate of 10°C min−1). The crucible was left in the oven to cool to room temperature. The obtained canary-colored g-C3N4 was ground in an agate mortar to a fine powder. The sample was denoted with the symbol gCN.

H2PtCl6 from water solution and Ru3(CO)12 from methanol solution were introduced onto a surface of the obtained gCN using the wet impregnation method. The amount of chloroplatinic acid and ruthenium dodecacarbonyl was adjusted to obtain 1.0 wt% of Pt and Ru on g-C3N4. gCN was contacted with the metal precursor solution for 2 h on a magnetic stirrer. The solvent was evaporated on a rotary evaporator. The samples were dried overnight at 80 °C. Catalyst samples and of gCN were stored in a desiccator over molecular sieves 4A. The catalysts were marked with the symbols Pt/gCN and Ru/gCN.

gCN and metal catalysts (in a dried form) were reduced at 525 °C in a tube furnace in a hydrogen flow (50 mL min−1), with a heating rate of 10°C min−1. The reduced gCN was marked with the symbol gCNr while the catalysts with the symbols Pt/gCNr and Ru/gCNr.

Characterization of the samples

The specific surface area (SSA) was determined by Brunauer–Emmett–Teller (BET) method, while the total pore volume and average pore diameter were calculated using the Barrett–Joyner–Halenda (BJH) method from the desorption branch of isotherms using a Micromeritics ASAP 2010 surface area and porosity analyzer (from N2 adsorption isotherms collected at 77 K).

The elemental analysis was investigated on Flash 2000 exhaust-gas analyzer (Thermo Fisher Scientific, Waltham, MA, USA) by combustion on 900–1000 °C.

An FEI Helios NanoLab 660 (Thermo Fisher Scientific, Waltham, MA, USA) electron microscope was used to obtain SEM images.

The powder X-ray diffraction patterns of the samples were obtained using a Bruker D8 Advance diffractometer by using CuKα radiation. The XRD data were collected over a 2θ range of 10–35° with a step size of 0.01° and the scanning time rate of 5 s.

XPS measurements were made with a Kratos Axis Ultra spectrometer (Kratos Analytical, Manchester, UK). The excitation source was a monochromatized aluminum X-ray source (Al Kα (1486.6 eV) operated at 10 mA and 15 kV. The charge referencing method used was the C (C, H) component of the C 1 s peak of adventitious carbon fixed at 284.8 eV. Spectroscopic data were processed by the CasaXPS ver. 2.3.17PR1.1 software (Casa Software Ltd., UK), using a peak-fitting routine with Shirley background and asymmetrical Voigt functions.

The Pt and Ru content were evaluated by the inductively coupled plasma (ICP) method. For ICP analysis, 15 mg of a sample (reduced at 300 °C) was added to an aqua regia solution for Pt and a mixture of H2SO4, aqua regia, and HF for Ru. The mixture was then autoclaved at 110 °C for 2 h. The digested solution was diluted with ultrapure water and analyzed for ICP by Agilent 720-ES ICP-OES. Measurements had showed that the content of Pt and Ru in the samples were 0.86 and 0.80 wt%, respectively.

Temperature programmed reduction measurements—hydrogen consumption and evolved gases analysis

The temperature-programmed reduction technique using the ASAP ChemiSorb 2705 instrument was applied to analyze the changes appearing in g-C3N4 during heating in hydrogen. A sample of ~ 10 mg was placed in a U-shaped quartz vessel and reduced in a mixture of 10 vol% H2 in Ar (99.999%, Linde) at a flow of 30 mL min−1 and heated with a rate of 10°C min−1. Hydrogen consumption was measured using thermal conductivity detector (TPR-TCD). In order to calculate the amount of consumed hydrogen, the TCD signal was calibrated by injecting 1054 µL portions of hydrogen into a flowing argon stream using a gas loop. All results were normalized to the same sample weight.

The identification of gaseous products of etching of gCN and metal/gCN samples was conducted using a gas analyzer ThermoStar made by Pfeiffer, model GDS301T2 with an analyzer QMA200 M, which was connected directly to the TPR instrument. The identification of fragmentation ions was carried out using the National Institute of Standards and Technology database (NIST) [33] and [34,35,36]. In the gas products of the metal/gCN catalyst reduction, the following ions were identified, those of m/z = 12, 13, 14, 15, 16 assigned to the fragmentation of CH4 [34], those of m/z = 14, 15, 16, 17 assigned to NH3 [35, 36], and those of m/z = 12, 13, 14, 26, 27, 28, evidencing the presence of HCN [36]. Moreover, the spectra showed the ions coming from hydrogen and argon (components of the reducing mixture), small amounts of H2O and traces of air from the surroundings.

Quantitative analysis of the released methane, ammonia and hydrogen cyanide was performed using infrared spectrometer FTS 3000 Bio-Rad (Bio-Rad, CA, USA) coupled with the TPR instrument (TPR-IR). The gases released from the TPR apparatus were directed to a gas cuvette equipped with NaCl windows. The optical path of the cuvette was 20 cm and its total volume was 15 mL. Such a small volume of the cuvette allows for a quick gas exchange (within 3–5 min) as the total gas flow rate during TPR measurement was 30 mL min−1.

Based on the FTIR spectra the plots presenting the dynamics of gas evolution were generated. For this purpose, the absorbance of characteristic bands was determined at: 2850–3180 cm−1 for methane, 780–1180 cm−1 for ammonia, 625–790 cm−1 for hydrogen cyanide. Having the maximum intensity of the band and using the Lambert–Beer law, the concentration of individual components was determined taking the absorbance cross-section (in cm2 mol−1) from Pacific Northwest National Laboratory (PNNL) quantitative database containing the vapor-phase infrared spectra of pure chemicals) [37], CH4 = 1.87 × 10–18, NH3 = 2.87 × 10–18, HCN = 3.6 × 10–18. On this basis, the charts were plotted showing quantitatively the dynamics of methane, ammonia and hydrogen cyanide release during the reduction/etching of gCN and metallic catalysts.

On the basis of the TPR-TCD curves, the activation energy of reduction in g-C3N4 was determined. The TPR-TCD curve is a differential curve showing hydrogen consumption (Fig. S3a). The curve was converted to a cumulative plot of hydrogen consumption (Fig. S3b), which illustrates the degree of decomposition of a sample α (Fig. S3c). The graphical method developed by Coats and Redfern (Fig. S3d) was used to evaluate activation energy (Ea) from TPR-TCD curves [38].

Gas phase thermochemistry data (ΔH°298 and G°298) for methane, ammonia and hydrogen cyanide was taken from the NIST database (National Institute of Standards and Technology) [39, 40] and for g-C3N4 from Kuntz and Deutschmann [41].

Quantum–mechanical calculations

In order to calculate the energy bond of particular bonds in g-C3N4, calculations were performed in Gaussian16W [42]. Since the aim of these calculations was to estimate the energy bonds for the conceptual mechanism of the g-C3N4 decomposition, the simple Hartree–Fock method (HF method) only was used with two basis sets of 3-21G and 6-311G(d). The final results of energy bonds presented in this work are calculated with a basis set 6-311G(d).

Results and discussion

Synthesis and physicochemical characterization of spongy g-C3N4

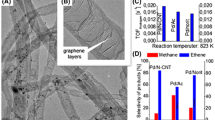

Graphitic carbon nitride was obtained by thermal condensation of dicyandiamide (DCDA) at 600 °C for 4 h and was denoted as gCN [43, 44]. In Fig. 1a, low-temperature nitrogen adsorption/desorption isotherms of the samples are presented. The specific surface area of gCN is 32 m2g−1 (Table 1) and is close to the values obtained by other researchers [45, 46]. gCN was reduced at 525 °C in hydrogen flow for 2 h (denoted as gCNr); SSA increased to 43 m2g−1. The increase in the SSA of g-C3N4 after heating in hydrogen was observed earlier by Maschmeyer et al. [47] and was assigned to the delamination of g-C3N4 to nanosheet (after H2 treatment at 550 °C) [48]. On the other hand, Niu et al. [48] claimed that reduction in g-C3N4 in hydrogen at 540 °C leads to the elimination of amino groups and forms nitrogen vacancies, which, however, do not change the crystal structure of g-C3N4. The low temperature N2 adsorption isotherms for gCN and gCNr (Fig. 1a) belong to type IV and the hysteresis loop to type H3, which is characteristic for plate-like particles giving rise to slit-shaped pores. Ru(CO)12 and H2PtCl6 were deposited on the surface of gCN by the impregnation method and reduced. The shape of adsorption/desorption nitrogen adsorption isotherms for the reduced systems of Pt/gCNr and Ru/gCNr are of type H1, which indicates the presence of cylindrical-like pore channels, and SSA increases to 142 and 171 m2g−1 for Pt and Ru catalysts, respectively (from initial 32 m2g−1 for gCN). The increase in the SSA of metal catalysts is accompanied by an increase in total pore volume and a decrease in average pore diameter (Table 1).

Porosity analysis shows that Pt and Ru nanoparticles (NPs) in the presence of hydrogen induce changes in the structure of g-C3N4 leading to a significant increase in SSA. We believe that this increase in SSA is the result of catalytic hydrogenation and hydrogenolysis of C–N bonds in carbon nitride by metal NPs, and not of the delamination of g-C3N4 to a nanosheet structure as stated in a paper by Maschmeyer et al. [47], which can be proved by the shape of the adsorption isotherm, characteristic of cylindrical-like pores. Metal nanoparticles like a Pac-Man from a famous computer game in the 1980s, nibbled g-C3N4 etching channels/tunnels in its structure. The phenomenon of etching channels by metal nanoparticles has been observed many times in pure carbon materials, mainly graphite and graphene [22, 23, 25, 26, 28, 29, 49], but never before for carbon nitride. In one recent paper [50], the term “Pac-Man mechanism” was used to describe this phenomenon, which seems to be very apt. In this context, the question of the size of metal NPs arises. The metal precursor was introduced onto the g-C3N4 surface by the impregnation method. After evaporating the solvent and drying the sample, it was reduced in a hydrogen flow from RT to 525 °C. During the temperature rise, the precursor is reduced first and metallic NPs are formed (Fig. S1). The reduction process of Pt and Ru precursors is completed below the temperature of 300 °C. Such catalysts (reduced at 300 °C) were described in our earlier work [51]. The resulting Pt and Ru crystallites had a size of 2.1 i 2.3 nm, respectively. We believe that such crystallites nibbled g-C3N4 etching channels/tunnels in its structure.

Powder X-ray diffraction tests were conducted to observe the changes of the crystal structure of carbon nitride (Fig. 1b). In the diffraction pattern of gCN, which like graphite is a layered-built material, a characteristic reflex is present at 27.75°2θ, corresponding to an interlayer spacing of 3.21 Å. After reduction in pristine gCN in hydrogen, a slight shift of reflex is recorded to smaller angles (to 27.65°2θ), which indicates an increase in interlayer spacing (d = 3.22 Å), which is probably related to the delamination of g-C3N4 as observed by Maschmeyer et al. [47]. However, in metal catalysts, the intensity of the reflex 27.75°2θ is clearly lowered, which proves a partial destruction of the gCN structure during the reduction at 525 °C. Simultaneously, changes caused by Ru NPs are greater than by Pt NPs. We believe that this is related to the hydrogenation activity of both metals; Ru is known for its high activity in hydrogenation of the C–N bond [52, 53]. This is confirmed indirectly by the results of elemental analysis (Table 1); the C/N atomic ratio is the highest for Ru/gCNr catalysts and is equal to 1.04 (summary formula C3N2.9), whereas for Pt/gCNr it is 0.88 (summary formula C3N3.4), which can prove that nitrogen is preferred to be eliminated by ruthenium from the structure of g-C3N4.

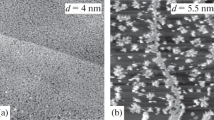

In Fig. 2, the SEM images of gCN and Ru and Pt catalysts after reduction in hydrogen at 525 °C for 2 h are presented. The SEM images showed no effect of the reduction on the structure of pristine gCN. Contrary to this, the structure of metal catalysts is significantly different from that of gCN. The surface of the catalysts resembles a porous sponge (pumice), hence the materials obtained can be called “spongy graphitic carbon nitride” (sgCN). We think that metal nanoparticles “migrate” in the structure of carbon nitride etching channels/tunnels in it, as was observed in the case of graphite [20, 26, 54, 55], graphene [21, 22, 24, 25, 27,28,29, 50], and recently for boron nitride [56].

X-ray photoelectron spectroscopy (XPS) is one of the most sensitive surface analysis methods for revealing information about the chemical state of elements in a sample. XPS is also commonly used to study the structure of graphitic carbon nitride. Figure 3a shows the C 1 s core-level XPS spectra for the gCN, gCNr, Pt/gCNr, and Ru/gCNr samples. Two basic bands can be distinguished in the C 1 s spectrum of carbon nitride; first at 284.8 eV derived from graphitic carbon (C–[C,H] adventitious carbon, AdC), which was used for energy calibration, and second at ~ 288.2 eV assigned to sp2-bonded carbon (N–C = N) in the heptazine rings [43] (denoted as Py – pyridinic carbon). The spectra also show a small band from nitrile species –C≡N [57, 58], which is sometimes observed for g-C3N4 synthesized at high temperatures [43]. Changes in the g-C3N4 spectrum after reduction (gCNr) are negligible and amount to a slight decrease in its intensity. On the other hand, the spectra of systems containing platinum and ruthenium are clearly evolving. Two main effects are observed: (1) a decrease in the intensity of the Py band indicating the progressive degradation of the C–N=C bonds in the g-C3N4 heptazine subunits, (2) the appearance of a new band at 284.2 eV, which can be assigned to the so-called defective carbon and should be considered as point defects in the graphite lattice [59, 60]. Both of these phenomena (degradation of the heptazine structures and the appearance of a new form of carbon) lead to an increase in the C/N ratio, which was 0.80 for gCN and 1.13 and 2.36 for Pt/gCNr and Ru/gCNr, respectively (Table S1). The increased C/N ratio in metallic systems was demonstrated by the results of elemental analysis presented earlier (Table 1). The above results show that during the reduction in the metal/gCN systems, the destruction of the heptazine subunits and elimination of carbon and nitrogen occur with the increase in the C/N ration due to the decrease in nitrogen—part of the carbon remains in the sample in the form of defective graphite-like structures.

Figure 3b presents the N 1 s core-level XPS spectra. There are four characteristic bands at 398.6, 399.4, 400.3 and 401.2 eV assigned to pyridinic nitrogen in the heptazine ring (denoted Py), nitrogen in amino group (NH2), nitrogen in imino group (NH), and quaternary nitrogen originating from the N–(C)3 component (Q), respectively [43, 61]. As in the C 1 s spectrum, the difference between gCN and gCNr is minimal. Much greater changes in the structure of g-C3N4 are generated in the presence of Pt and Ru. The intensities of the Pt/gCNr and Ru/gCNr spectra drop significantly. It should be noted that the decrease is considerably greater for ruthenium than for platinum and it affects all the forms of nitrogen to a comparable degree (Table S2). That means that all the forms of nitrogen (Py, NH2, NH, Q) are eliminated from the g-C3N4 structure to a comparable extent.

The XPS technique also allowed us to observe the surroundings and oxidation degree of platinum and ruthenium. The XPS spectrum of the Pt 4f region of the Pt/gCNr sample is shown in Fig. 3c. There are three doublets in the spectrum. The first doublet at 70.8 and 74.2 eV corresponds to the 4f7/2, and 4f5/2 states of Pt0, respectively. The second doublet at 73.5 and 76.9 eV corresponds to the 4f7/2 and 4f5/2 states of platinum (II) coordinated to nitrogen atoms, respectively [51, 62,63,64,65]. Finally, the doublet at 76.7 and 79.1 eV corresponds to platinum (IV), also coordinated to nitrogen atoms [66, 67]. The presence of platinum oxides was excluded, since no characteristic bands were observed in the O 1 s spectrum (Fig. S2). Most of platinum (71.1%) forms metallic crystallites while the rest appears in the nitrogen-coordinated oxidized form.

Ru 3p core-level XPS spectrum of Ru/gCNr sample is shown at Fig. 3d. The presence of metallic ruthenium is evidenced by the doublet at 461.1 and 483.6 eV for 3p3/2, and 3p1/2 states of Ru0, respectively [68]. The second doublet at 466.1 and 488.3 eV derives from nitrogen-coordinated oxidized forms of ruthenium [69,70,71]. Finally, a doublet at 462.8 and 485.0 eV with a doublet separation of 22.2 eV originates from RuO2 [68], which is confirmed by the peak observed at 529.4 eV with satellite at 531.2 eV in the O 1 s spectrum (Fig. S2). Ruthenium is known to be easily oxidized even at room temperature. Hence, we believe that RuO2 was formed by exposing the reduced sample to ambient oxygen. Ruthenium in metallic form accounts for 62.3% of its total amount and in oxidized form 37.7%. We believe that the oxidized forms of Pt and Ru are created on the surface of metal NPs but remain in metallic form inside. Adsorption of carbon nitride structure elements on the surface of metal NPs should first occur, in order to enable the hydrogenation/hydrogenolysis of C–N bonds. Such interactions do occur, as evidenced by the increasing number of reports by many authors on the observation of metal-nitrogen interactions in so-called single-metal catalysts [4, 51, 64, 72,73,74].

Insight into the nibbling process

The temperature-programmed reduction technique (TPR) was used to gain insight into the etching of g-C3N4. The classic TPR-H2 technique was used to observe hydrogen consumption with the thermal conductivity detector (TPR-TCD) as well as the TPR technique coupled with mass spectrometry (TPR-MS) and infrared spectroscopy (TPR-IR).

The TPR-MS and TPR-IR techniques allowed for identification of products formed during the etching of g-C3N4. During the TPR measurements, the gaseous products of the etching of g-C3N4 were monitored using a mass spectrometer in the range m/z = 1–53 (Fig. 4).

In the gaseous products of the reduction, ions with m/z = 12, 13, 14, 15, 16 generating from methane fragmentation were observed [34, 75]; ions with m/z = 14, 15, 16, 17 derived from ammonia [35, 75], and ions with m/z = 26, 27, 28 indicating the presence of hydrogen cyanide [75]. Moreover, signals from hydrogen and argon were recorded (from the reducing mixture) as well as small amounts of water and traces of air from the surroundings. The presence of CH4, NH3 and HCN in the etching products of g-C3N4 was confirmed by infrared spectroscopy (TPR-IR). Carbon nitride etching products were directed from the TPR apparatus to a gas cuvette placed in the IR spectrometer. Bands of CH4, NH3 and HCN were identified in the carbon nitride etching products on the basis of the reference spectra available at The National Institute of Standards and Technology (NIST) [33].

The changes that take place in g-C3N4 during reduction were observed by monitoring of the released gases using infrared spectroscopy (Fig. 5a, b) while the hydrogen consumption was monitored by a thermal conductivity detector (TPR-TCD)—Fig. 5. Nibbling of pristine gCN starts at ~ 570 °C and proceeds with the highest speed at ~ 710 °C—Fig. 5b1, c1. The presence of metal on the gCN surface significantly lowers the temperature at which carbon nitride etching begins. The temperature at which etching starts, increases in the following order:

Temperature programmed reduction in gCN and metallic catalysts. (a) FTIR spectra recorded with increasing temperature (spectrum every 10 °C); (b) the amount of evolved gases during the TPR-IR measurements; (c) hydrogen consumption during TPR-TCD measurements (10 vol% H2/Ar, flow rate 30 mL min−1, 10°C min−1)

The observed differences in reduction temperatures reflect different reactivities of both metals in hydrogenation of the C–N bonds. Ruthenium is known for its high activity in hydrogenolysis reaction of the C–N bond, higher than for platinum [53]; hence, the reaction is initiated at the lowest temperature (300 °C). Considering hydrogen consumption from the TPR-TCD plots (Fig. 5c), apparent activation energies (Ea [kJ mol−1]) were calculated (Fig. S3) and they are:

The reduction/etching of gCN and Pt/gCN occurs as one step (one reduction peak); on the TPR-TCD plot for Ru/gCN there are two well separated signals (Fig. 5b3, c3)—Ea was calculated for each of them. The obtained activation energies for Pt/gCN and Ru/gCN are close to Ea of hydrogenation of amorphous carbon by Pt (140.1 ± 16.7 kJ mol−1) and at the same time lower than for graphite supported platinum (181.9 ± 16.7 kJ mol−1) [76].

The quantitative measurements of the gases released during etching of g-C3N4 are presented in Fig. 5b showing the results of TPR-IR investigations. Etching of pristine g-C3N4 is accompanied mainly by the emission of hydrogen cyanide and ammonia (Fig. 5a1, b1). The molar ratio of HCN:NH3 is close to 3:1, which indicates that hydrogenation of g-C3N4 can take place according to the following reaction equation:

Although the value of ΔH° is quite low, the reaction is exothermic. At the same time, the negative value of ΔG° indicates that the reaction is spontaneous.

Contrary to pristine g-C3N4, in the presence of metals the first etching products are ammonia and methane (Fig. 5a2, b2, a3, b3). For both the platinum and ruthenium catalysts, the molar ratio of NH3:CH4 is close to one. This means that the reaction can occur according to the equation:

Reaction (2) is strongly exothermic and spontaneous. We believe that this reaction is the most important one during the etching of g-C3N4 in the presence of metals.

At higher temperatures, hydrogen cyanide appears in reaction products, and molar ratios for HCN:NH3:CH4 are approximately 1:3:2 (for Pt and Ru catalysts), which implies that etching of g-C3N4 can be described by the following reaction:

for which ΔH° i ΔG° are also very negative.

Etching of g-C3N4 in the presence of ruthenium occurs in two steps (contrary to gCN and Pt/gCN, which is a one-step process). In the first stage, the reaction products are only NH3 and CH4 appearing in equal amounts (Fig. 5a3, b3), which indicates the course of the reaction (2). In the second stage of etching (at higher temperature), the main products are HCN and NH3 (and small amounts of CH4) implying that reaction (1) and/or (4) takes place:

In fact, the etching reactions (hydrogenation/hydrogenolysis) of g-C3N4 can occur according to each of the above Eqs. (1–4) and their participation will be varied depending on the intristic activity of metals. The values of ΔH° and ΔG° are provided only for determining the probability of a specific reaction that can take place during the degradation of g-C3N4.

Theoretical considerations and g-C3N4 etching mechanism

In the structure of g-C3N4 nitrogen can be bonded to carbon through four different ways (Fig. 6):

1 | N–(C)3 | Graphitic (quaternary nitrogen) | 3.3 eV |

2 | NH–(C)2 | Imino-nitrogen | 3.9 eV |

3 | –NH2 | Amino-nitrogen | 4.2 eV |

4 | –N=C– | Pirydinic nitrogen | 0.2 + 4.2 eV |

These bonds have different strengths, which have been estimated by calculations carried out in Gaussian16W [42] using the Hartree–Fock (HF) method and a basis set 6-311G(d). The results of the calculations are presented above in electron-volts. The series of chemical bond strengths was put in order according to the susceptibility of breaking the chemical bond. Thus, following the order of chemical bond strengths, one can propose the mechanism presented in Fig. 6. In the first step of g-C3N4 reduction, the bond (1) is broken, since its strength has the value of 3.3 eV. The next bond likely to be broken is bond (2) Fig. 6. Then, elimination of amino groups takes place (3), and almost at the same time hydrogenation of pirydinic nitrogen in the heptazine ring occurs (4) along with further hydrogenolysis of the single C–N bond (4’.), which causes the opening of the aromatic ring in heptazine. This step seems to be the key step for the subsequent stages of g-C3N4 destruction. It is highly probable that in the next steps, the amine group or methylamine can be eliminated, which undergoes further decomposition leading to ammonia and methane (4″). Once the aromatic ring of heptazine opens up, methane may be eliminated easily too (5). The direct elimination of HCN is also possible under higher temperatures (6). The sequence of chemical reactions shown above is consistent with the dynamics of releasing of ammonia, methane and hydrogen cyanide measured using the TPR-IR method described in the previous section.

It should be underlined at this point that the proposed mechanism of the g-C3N4 decomposition was based on estimations only. These estimations were obtained from bond energy calculations of particular bonds, taking into account simple theoretical model mentioned above (HF method and 6-311G(d) basis set). Moreover, not all the factors that influence the stability of particular bonds in the presence of metal nanoparticles were considered in the calculations, i.e., activation energy of reaction. The aim of our calculations was to put in order the strength of particular bonds according to their susceptibility to breaking and to propose the conceptual mechanism of hydrogenation/hydrogenolysis of graphitic carbon nitride that leads to the formation of sgCN.

Conclusion

On the basis of the obtained results one can present the structure of graphitic carbon nitride that undergoes the hydrogen reduction process at higher temperature and suggest the sequence of transformations that lead to formation of “spongy graphitic carbon nitride” (sgCN).

The structure of sgCN appears as a strongly defective graphitic carbon nitride. Metal nanoparticles (Pt, Ru) are the centers of hydrogen dissociation, which “attack” g-C3N4 causing the hydrogenation and hydrogenolysis of C–N bonds. The reactions take place on the surface of metal NPs, which are covered with oxidized forms of Pt and Ru capable of strong interactions with nitrogen, which was confirmed by XPS studies. Metal nanoparticles “move” through the structure of g-C3N4 like a “Pac-Man” etching the channels/tunnels in it, which produces a structure resembling a pumice stone with a well-developed specific surface area. So far, the phenomenon of channeling has been observed only for carbon materials [20,21,22, 24,25,26,27,28,29, 50, 54, 55, 77] as well as for boron nitride [56], but never for g-C3N4.

We do hope that the presented method of obtaining a high-surface area sgCN will inspire other scientists to attempt further modifications of g-C3N4. Selection of the right metal and the manner of its deposition on the g-C3N4 surface, its content as well as the adjustment of appropriate reduction conditions, create a wide range of possibilities to control over the structure of the resulting sgCN.

References

Liu AY, Cohen ML (1989) Prediction of new low compressibility solids. Science 245:841–842

Wang XC, Maeda K, Thomas A, Takanabe K, Xin G, Carlsson JM, Domen K, Antonietti M (2009) A metal-free polymeric photocatalyst for hydrogen production from water under visible light. Nat Mater 8:76–80

Miller TS, Jorge AB, Suter TM, Sella A, Cora F, McMillan PF (2017) Carbon nitrides: synthesis and characterization of a new class of functional materials. Phys Chem Chem Phys 19:15613–15638

Wang S, Zhang J, Li B, Sun H, Wang S (2021) Engineered graphitic carbon nitride-based photocatalysts for visible-light-driven water splitting: a review. Energy Fuels 35:6504–6526

Dong F, Wu LW, Sun YJ, Fu M, Wu ZB, Lee SC (2011) Efficient synthesis of polymeric g-C3N4 layered materials as novel efficient visible light driven photocatalysts. J Mater Chem 21:15171–15174

Xu J, Wang YJ, Zhu YF (2013) Nanoporous graphitic carbon nitride with enhanced photocatalytic performance. Langmuir 29:10566–10572

Goettmann F, Fischer A, Antonietti M, Thomas A (2006) Chemical synthesis of mesoporous carbon nitrides using hard templates and their use as a metal-free catalyst for friedel-crafts reaction of benzene. Angew Chem Int Ed 45:4467–4471

Jun YS, Hong WH, Antonietti M, Thomas A (2009) Mesoporous, 2D hexagonal carbon nitride and titanium nitride/carbon composites. Adv Mater 21:4270–7274

Li LF, Zhang JH, Zhang Q, Wang XH, Dai WL (2021) Superior sponge-like carbon self-doping graphitic carbon nitride nanosheets derived from supramolecular pre-assembly of a melamine-cyanuric acid complex for photocatalytic H2 evolution. Nanotechnology 32:155604

Huang T, Pan S, Shi L, Yu A, Wang X, Fu Y (2020) Hollow porous prismatic graphitic carbon nitride with nitrogen vacancies and oxygen doping: a high-performance visible light-driven catalyst for nitrogen fixation. Nanoscale 12:1833–1841

Lee JH, Park MJ, Yoo SJ, Jang JH, Kim HJ, Nam SW, Yoon CW, Kim JY (2015) A highly active and durable Co–N–C electrocatalyst synthesized using exfoliated graphitic carbon nitride nanosheets. Nanoscale 7:10334–10339

Todorova N, Papailias I, Giannakopoulou T, Ioannidis N, Boukos N, Dallas P, Edelmannová M, Reli M, Kočí K, Trapalis C (2020) Photocatalytic H2 evolution, CO2 reduction, and NOx oxidation by highly exfoliated g-C3N4. Catalysts 10:1147

Wang CF, Han TX, Xin C, Miao H (2021) Synthesizing the high surface area g-C3N4 for greatly enhanced hydrogen production. Catalysts 11:832

Gao XC, Feng J, Su DW, Ma YC, Wang GX, Ma HY, Zhang JT (2019) In-situ exfoliation of porous carbon nitride nanosheets for enhanced hydrogen evolution. Nano Energy 59:598–609

Zhu YP, Ren TZ, Yuana ZY (2015) Mesoporous phosphorus-doped g-C3N4 nanostructured flowers with superior photocatalytic hydrogen evolution performance. ACS Appl Mater Interfaces 7:16850–16856

Zhou L, Zhang HY, Sun HQ, Liu SM, Tade MO, Wang SB, Jin WQ (2016) Recent advances in non-metal modification of graphitic carbon nitride for photocatalysis: a historic review. Catal Sci Technol 6:7002–7023

Zhao ZK, Dai YT, Lin JH, Wang GR (2014) Highly-ordered mesoporous carbon nitride with ultrahigh surface area and pore volume as a superior dehydrogenation catalyst. Chem Mater 26:3151–3161

Tomita A, Tamai Y (1972) Hydrogenation of carbons catalyzed by transition-metals. J Catal 27:293–300

Tomita A, Sato N, Tamai Y (1974) Hydrogenation of carbons catalyzed by nickel, platinum and rhodium. Carbon 12:143–149

Tomita A, Tamai Y (1974) Optical microscopic study on the catalytic hydrogenation of graphite. J Phys Chem 78:2254–2258

Campos LC, Manfrinato VR, Sanchez-Yamagishi JD, Kong J, Jarillo-Herrero P (2009) Anisotropic etching and nanoribbon formation in single-layer graphene. Nano Lett 9:2600–2604

Datta SS, Strachan DR, Khamis SM, Johnson ATC (2008) Crystallographic etching of few-layer graphene. Nano Lett 8:1912–1915

Pizzocchero F, Vanin M, Kling J, Hansen TW, Jacobsen KW, Bøggild P, Booth TJ (2014) Graphene edges dictate the morphology of nanoparticles during catalytic channeling. J Phys Chem C 118:4296–4302

Baaziz W, Melinte G, Ersen O, Pham-Huu C, Janowska I (2014) Effect of nitriding/nanostructuration of few layer graphene supported iron-based particles; catalyst in graphene etching and carbon nanofilament growth. Phys Chem Chem Phys 16:15988–15993

Wei JK, Xu Z, Wang H, Tian XZ, Yang SZ, Wang LF, Wang WL, Bai XD (2014) In-situ TEM imaging of the anisotropic etching of graphene by metal nanoparticles. Nanotechnology 25:7

Lukas M, Meded V, Vijayaraghavan A, Song L, Ajayan PM, Fink K, Wenzel W, Krupke R (2013) Catalytic subsurface etching of nanoscale channels in graphite. Nat Commun 4:7

Booth TJ, Pizzocchero F, Andersen H, Hansen TW, Wagner JB, Jinschek JR, Dunin-Borkowski RE, Hansen O, Boggild P (2011) Discrete dynamics of nanoparticle channelling in suspended graphene. Nano Lett 11:2689–2692

Severin N, Kirstein S, Sokolov IM, Rabe JP (2009) Rapid trench channeling of graphenes with catalytic silver nanoparticles. Nano Lett 9:457–461

Ci L, Xu ZP, Wang LL, Gao W, Ding F, Kelly KF, Yakobson BI, Ajayan PM (2008) Controlled nanocutting of graphene. Nano Res 1:116–122

Xu J, Wu F, Wu HT, Xue B, Li YX, Cao Y (2014) Three-dimensional ordered mesoporous carbon nitride with large mesopores: synthesis and application towards base catalysis. Micropor Mesopor Mat 198:223–229

Xu, J.;Chen, T.;Jiang, Q.; Li, Y. X. Utilization of Environmentally Benign Dicyandiamide as a Precursor for the Synthesis of Ordered Mesoporous Carbon Nitride and its Application in Base-Catalyzed Reactions. Chem.-Asian J. 2014, 9, 3269–3277.

Li XH, Wang XC, Antonietti M (2012) Mesoporous g-C3N4 nanorods as multifunctional supports of ultrafine metal nanoparticles: hydrogen generation from water and reduction of nitrophenol with tandem catalysis in one step. Chem Sci 3:2170–2174

Linstrom PJ, Mallard WG (2021) NIST Chemistry WebBook, NIST Standard Reference Database Number 69. National Institute of Standards and Technology, Gaithersburg

Wei B, Zhang Y, Wang X, Lu D, Lu GC, Zhang BH, Tang YJ, Hutton R, Zou Y (2014) Fragmentation mechanisms for methane induced by 55 eV, 75 eV, and 100 eV electron impact. J Chem Phys 140:8

Rejoub R, Lindsay BG, Stebbings RF (2001) Electron-impact ionization of NH3 and ND3. J Chem Phys 115:5053–5058

Wuest M; Evans DS; von Steiger R (2007) Fragmentation patterns and total ionization cross sections. In: Wuest M, Evans DS, von Steiger R (eds) Calibration of particle instruments in space physics. ESA Publications Division Keplerlaan 1, 2200 AG Noordwijk, The Netherlands, pp 555–570

Sharpe SW, Johnson TJ, Sams RL, Chu PM, Rhoderick GC, Johnson PA (2004) Gas-phase databases for quantitative infrared spectroscopy. Appl Spectrosc 58:1452–1461

Coats AW, Redfern JP (1964) Kinetic parameters from thermogravimetric data. Nature 201:68–69

Cox JD, Wagman DD, Medvedev VA (1989) CODATA key values for thermodynamics. Hemisphere Publishing Corp, New York

Chase MW Jr (1998) NIST-JANAF thermochemical tables, monograph 9. J Phys Chem Ref Data 9:1–1951

Kuntz C, Kuhn C, Weickenmeier H, Tischer S, Börnhorst M, Deutschmann O (2021) Kinetic modeling and simulation of high-temperature by-product formation from urea decomposition. Chem Eng Sci 246:116876

Frisch MJ, Trucks GW, Schlegel HB, Scuseria GE, Robb MA, Cheeseman JR, Scalmani G, Barone V, Petersson GA, Nakatsuji H, Li X, Caricato M, Marenich AV, Bloino J, Janesko BG, Gomperts R, Mennucci B, Hratchian HP, Ortiz JV, Izmaylov AF, Sonnenberg JL, Williams A, Ding F, Lipparini F, Egidi F, Goings J, Peng B, Petrone A, Henderson T, Ranasinghe D, Zakrzewski VG, Gao J, Rega N, Zheng G, Liang W, Hada M, Ehara M, Toyota K, Fukuda R, Hasegawa J, Ishida M, Nakajima T, Honda Y, Kitao O, Nakai H, Vreven T, Throssell K, Montgomery JA Jr, Peralta JE, Ogliaro F, Bearpark MJ, Heyd JJ, Brothers EN, Kudin KN, Staroverov VN, Keith TA, Kobayashi R, Normand J, Raghavachari K, Rendell AP, Burant JC, Iyengar SS, Tomasi J, Cossi M, Millam JM, Klene M, Adamo C, Cammi R, Ochterski JW, Martin RL, Morokuma K, Farkas O, Foresman JB, Fox DJ (2016) Gaussian 16 Rev C.01. Gaussian Inc, Wallingford

Alwin E, Nowicki W, Wojcieszak R, Zielinski M, Pietrowski M (2020) Elucidating the structure of the graphitic carbon nitride nanomaterials via X-ray photoelectron spectroscopy and X-ray powder diffraction techniques. Dalton Trans 49:12805–12813

Alwin E, Kočí K, Wojcieszak R, Zieliński M, Edelmannová M, Pietrowski M (2020) Influence of high temperature synthesis on the structure of graphitic carbon nitride and its hydrogen generation ability. Materials 13:2756

Devthade V, Kulhari D, Umare SS (2018) Role of precursors on photocatalytic behavior of graphitic carbon nitride. Mater Today-Proc 5:9203–9210

Zhao ZH, Ma Y, Fan JM, Xue YQ, Chang HH, Masubuchi Y, Yin S (2018) Synthesis of graphitic carbon nitride from different precursors by fractional thermal polymerization method and their visible light induced photocatalytic activities. J Alloys Compd 735:1297–1305

Li XB, Hartley G, Ward AJ, Young PA, Masters AF, Maschmeyer T (2015) Hydrogenated defects in graphitic carbon nitride nanosheets for improved photocatalytic hydrogen evolution. J Phys Chem C 119:14938–14946

Niu P, Yin LC, Yang YQ, Liu G, Cheng HM (2014) Increasing the visible light absorption of graphitic carbon nitride (melon) photocatalysts by homogeneous self-modification with nitrogen vacancies. Adv Mater 26:8046–8052

Sang Y, Jin CH, Habib M, Song L (2018) Confined growth of carbon nanotubes in nanocutting channel on highly oriented pyrolytic graphite. NANO 13:7

Qiu ZY, Song L, Zhao J, Li ZY, Yang JL (2016) The nanoparticle size effect in graphene cutting: a “Pac-Man” mechanism. Angew Chem Int Ed 55:9918–9921

Alwin E, Wojcieszak R, Kočí K, Edelmannová M, Zieliński M, Suchora A, Pędziński T, Pietrowski M (2022) Reductive modification of carbon nitride structure by metals—the influence on structure and photocatalytic hydrogen evolution. Materials 15:710

Sinfelt JH (1969) Catalytic hydrogenolysis over supported metals. Catal Rev 3:175–205

Meitzner G, Mykytka WJ, Sinfelt JH (1986) Metal-catalyzed reactions of methylamine in the presence of hydrogen. J Catal 98:513–521

Keep C (1980) Studies of the nickel-catalyzed hydrogenation of graphite. J Catal 66:451–462

Konishi S, Sugimoto W, Murakami Y, Takasu Y (2006) Catalytic creation of channels in the surface layers of highly oriented pyrolytic graphite by cobalt nanoparticles. Carbon 44:2338–2340

Ma L, Zeng XC (2017) Catalytic directional cutting of hexagonal boron nitride: the roles of interface and etching agents. Nano Lett 17:3208–3214

Wu GP, Lu CX, Wu XP, Zhang SC, Fu H, Ling LC (2004) X-ray photoelectron spectroscopy investigation into thermal degradation and stabilization of polyacrylonitrile fibers. J Appl Polym Sci 94:1705–1709

Tao F, Wang ZH, Qiao MH, Liu Q, Sim WS, Xu GQ (2001) Covalent attachment of acetonitrile on Si(100) through Si–C and Si–N linkages. J Chem Phys 115:8563–8569

Blume R, Rosenthal D, Tessonnier J-P, Li H, Knop-Gericke A, Schlögl R (2015) Characterizing graphitic carbon with X-ray photoelectron spectroscopy: a step-by-step approach. ChemCatChem 7:2871–2881

Susi T, Pichler T, Ayala P (2015) X-ray photoelectron spectroscopy of graphitic carbon nanomaterials doped with heteroatoms. Beilstein J Nanotechnol 6:177–192

Akaike K, Aoyama K, Dekubo S, Onishi A, Kanai K (2018) Characterizing electronic structure near the energy gap of graphitic carbon nitride based on rational interpretation of chemical analysis. Chem Mater 30:2341–2352

Hino S, Matsumoto K, Yamakado H, Yakushi K, Kuroda H (1989) Photoelectron spectra of metallic conducting Pt-phthalocyanine radical salts. Synth Met 32:301–308

Battistoni, C.;Giuliani, A. M.;Paparazzo, E.; Tarli, F. Platinum complexes of the methyl esters of dithiocarbazic acid and 3-phenyldithiocarbazic acid. J. Chem. Soc., Dalton Trans. 1984, https://doi.org/10.1039/dt9840001293, 1293.

Zhang LW, Long R, Zhang YM, Duan DL, Xiong YJ, Zhang YJ, Bi YP (2020) Direct observation of dynamic bond evolution in single-atOm Pt/C3N4 catalysts. Angew Chem Int Ed 59:6224–6229

Li Y, Wang Z, Xia T, Ju H, Zhang K, Long R, Xu Q, Wang C, Song L, Zhu J, Jiang J, Xiong Y (2016) Implementing metal-to-ligand charge transfer in organic semiconductor for improved visible-near-infrared photocatalysis. Adv Mater 28:6959–6965

Yin H, Li S-L, Gan L-Y, Wang P (2019) Pt-embedded in monolayer g-C3N4 as a promising single-atom electrocatalyst for ammonia synthesis. J Mater Chem A 7:11908–11914

Cahen D, Lester JE (1973) Mixed and partial oxidation states—photoelectron spectroscopic evidence. Chem Phys Lett 18:108–111

Morgan DJ (2015) Resolving ruthenium: XPS studies of common ruthenium materials. Surf Interface Anal 47:1072–1079

Clark DT, Woolsey IS, Robinson SD, Laing KR, Wingfield JN (1977) Complexes of the platinum metals Electron spectroscopy for chemical analysis studies of some nitrosyl, aryldiazo, and aryldiimine derivatives of ruthenium, osmium, rhodium, and iridium. lnorg Chem 16:1201–1206

Folkesson B, Bjorøy M, Pappas J, Skaarup S, Aaltonen R, Swahn C-G (1973) ESCA studies on the charge distribution in some dinitrogen complexes of rhenium, iridium, ruthenium, and osmium. Acta Chem Scand 27:287–302

Lu BZ, Guo L, Wu F, Peng Y, Lu JE, Smart TJ, Wang N, Finfrock YZ, Morris D, Zhang P, Li N, Gao P, Ping Y, Chen SW (2019) Ruthenium atomically dispersed in carbon outperforms platinum toward hydrogen evolution in alkaline media. Nat Commun 10:11

Mori K, Osaka R, Naka K, Tatsumi D, Yamashita H (2019) Ultra-low loading of Ru clusters over graphitic carbon nitride: a drastic enhancement in photocatalytic hydrogen evolution activity. ChemCatChem 11:1963–1969

Zhou P, Lv F, Li N, Zhang YL, Mu ZJ, Tang YH, Lai JP, Chao YG, Luo MC, Lin F, Zhou JH, Su D, Guo SJ (2019) Strengthening reactive metal-support interaction to stabilize high-density Pt single atoms on electron-deficient g-C3N4 for boosting photocatalytic H2 production. Nano Energy 56:127–137

Zeng ZX, Su Y, Quan X, Choi WY, Zhang GH, Liu N, Kim B, Chen S, Yu HT, Zhang SS (2020) Single-atom platinum confined by the interlayer nanospace of carbon nitride for efficient photocatalytic hydrogen evolution. Nano Energy 69:10

Paschmann GT, Daly PW (1998) ISSI Book on Analysis Methods for Multi-Spacecraft Data. ESA Publications Division for the International Space Science Institute, Noordwijk

Santiesteban J, Fuentes S, Yacaman MJ (1983) Structural and kinetic studies of carbon methanation catalysis by small platinum particles. J Mol Catal 20:213–231

McKee DW (1974) Effect of metallic impurities on the gasification of graphite in water vapor and hydrogen. Carbon 12:453–464

Acknowledgements

This research was funded by Grant No. POWR.03.02.00-00-I023/17, co-financed by the European Union through the European Social Fund under the Operational Program Knowledge Education Development. The authors thank the Center for Advanced Technology, Adam Mickiewicz University for providing the SEM photos.

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all the authors. All the authors have given approval to the final version of the manuscript. Conceptualization was contributed by MP, EA; writing—original draft, was contributed by MP, EA, IG; writing—review and editing, was contributed by MP, EA, MZ, IG, ZP; investigation was contributed by EA, MP, MZ, ZP, AS; methodology was contributed by MP, EA, IG; IG contributed to software; supervision was contributed by MP; visualization was contributed by MP, EA.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Handling Editor: Christopher Blanford.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Electronic Supplementary Material Description of the method for determining the activation energy of the g-C3N4 reduction reaction from TPR measurements.

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alwin, E., Zieliński, M., Suchora, A. et al. High surface area, spongy graphitic carbon nitride derived by selective etching by Pt and Ru nanoparticles in hydrogen. J Mater Sci 57, 15705–15721 (2022). https://doi.org/10.1007/s10853-022-07621-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07621-x