Abstract

Shape memory alloys (SMAs) exhibit unique properties, including the ability to restore their original shape by temperature variations. One of the grand challenges of the aerospace industry is to develop SMAs with transformation temperatures above 100 ºC with high thermal conductivity. This study focuses on the effects of heat treatments on the microstructure, thermal and electrical conductivities of the Ni50.9Ti29.6Hf19.5 SMA that features good combination between transformation temperatures and physical properties desirable for aerospace applications, such as actuators. We found that heat treatments at 550 °C or 700 °C for 3 or 50 h affect the microstructure significantly, leading to formation of nanometer-size Hf-rich precipitates. As a result, the Martensite-to-Austenite phase transformation temperature is shifted from 100 °C up to 205 °C. Moreover, these heat treatments affect the electrical and thermal conductivities. The maximum room-temperature values of both thermal and electrical conductivities were recorded after heat treatment at 700 ºC for 3 h and are as high as \(\kappa =13.1\pm 0.4\mathrm{ W }{\mathrm{m}}^{-1} {\mathrm{K}}^{-1}\) and \(\sigma =(9\pm 0.27)\times {10}^{3}\mathrm{ S }{\mathrm{cm}}^{-1}\), respectively. The correlation between transformation temperature, microstructure, and thermal and electrical conductivities provides us with useful knowledge required for high temperature SMA design.

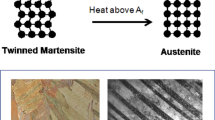

Graphical Abstract

taken from the surface of the Ni50.9Ti29.6Hf19.5 alloy in the as-received condition, b Energy-dispersive X-ray spectroscopy (EDS) analysis showing the Kα and M signals of oxygen and hafnium in the hafnium oxide (HfO2) phase

Similar content being viewed by others

References

Stoeckel D (2000) Nitinol medical devices and implants. Minim Invasive Ther Allied Technol 9:81–88

Duerig T, Pelton A, Sto D (1999) An overview of nitinol medical applications. Mater Sci Eng A273–275:149–160

Costanza G, Tata ME (2020) Developments and New Applications. Mater 3:1–16

Doroftei I, Stirbu B (2014) Application of Ni-Ti shape memory alloy actuators in a walking micro-robot. Mechanika 20:70–79

Chang-Jun Q, Pei-Sun M, Qin Y (2004) A prototype micro-wheeled-robot using SMA actuator. Sens Actuators 113:94–99

Kim B, Lee MG, Lee YP, Kim Y, Lee G (2006) An earthworm-like micro robot using shape memory alloy actuator. Sens Actuators 125:429–437

Chang SH, Wu SK (2007) Internal friction of B2 → B19 martensitic transformation of Ti 50 Ni 50 shape memory alloy under isothermal conditions. Mater Sci Eng A 454–455:379–383

Potapov PL, Da Silva EP (2000) Time response of shape memory alloy actuators. J Intell Mater Syst Struct 11:125–134

FT Calkins, JH Mabe, RT Ruggeri (2008) Overview of boeing’s shape memory alloy based morphing aerostructures in: SMASIS2008–648.

CL Packer Software staff dominate ’88 hospital budgets., Hospitals (Lond). 62 (1988).

Faulkner MG, Amalraj JJ, Bhattacharyya A (2000) Experimental determination of thermal and electrical properties of Ni-Ti shape memory wires. Smart Mater Struct 9:632–639

Rondelli G (1996) Corrosion resistance tests on NiTi shape memory alloy. Biomaterials 17:2003–2008

Soboyejo WO, Srivatsan, TS (Eds.) (2006) Advanced structural materials: properties, design optimization, and applications (1st ed.). CRC Press. https://doi.org/10.1201/9781420017465

Buchheit TE, Susan DF, Massad JE, McElhanon JR, Noebe RD (2016) Mechanical and functional behavior of high-temperature Ni-Ti-Pt shape memory alloys Metall. Mater Trans A Phys Metall Mater Sci 47:1587–1599

Kumar PK, Lagoudas DC, Zanca KJ, Lagoudas MZ (2006) Thermomechanical characterization of high temperature SMA actuators Smart Struct Mater 2006. Act Mater Behav Mech. 6170:617012

Saghaian SM, Karaca HE, Tobe H, Turabi AS, Saedi S, Saghaian SE, Chumlyakov YI, Noebe RD (2017) High strength NiTiHf shape memory alloys with tailorable properties. Acta Mater 134:211

Karakoc O, Hayrettin C, Bass M, Wang SJ, Canadinc D, Mabe JH, Lagoudas DC, Karaman I (2017) Effects of upper cycle temperature on the actuation fatigue response of NiTiHf high temperature shape memory alloys. Acta Mater 138:185–197

Karaca HE, Acar E, Tobe H, Saghaian SM, Acar E, Tobe H, Nitihf- SMS, Karaca HE, Acar E, Tobe H, Saghaian SM (2014) NiTiHf-based shape memory alloys. Mater Sci Technol 30(13):1530–1544

Benafan O, Bigelow GS, Garg A, Noebe RD, Gaydosh DJ, Rogers RB (2021) Processing and Scalability of NiTiHf High - Temperature Shape Memory Alloys. Shape Memory and Superelasticity 7:109–165

Hornbuckle BC, Sasaki TT, Bigelow GS, Noebe RD, Weaver ML, Thompson GB (2015) Structure-property relationships in a precipitation strengthened Ni-297Ti-20Hf (at%) shape memory alloy. Mater Sci Eng A 637:63–69

Evirgen A, Karaman I, Santamarta R, Pons J, Noebe RD (2015) Microstructural characterization and shape memory characteristics of the Ni503Ti347Hf15 shape memory alloy. Acta Mater 83:48–60

Ded GS (2010) Characterization of Ni-rich NiTiHf based high temperature shape memory alloys. University of Kentucky, Kentucky

Evirgen A, Karaman I, Santamarta R, Pons J, Hayrettin C, Noebe RD (2016) Relationship between crystallographic compatibility and thermal hysteresis in Ni-rich NiTiHf and NiTiZr high temperature shape memory alloys. Acta Mater 121:374–383

Buytoz S, Dagdelen F, Qader IN, Kok M, Tanyildizi B (2021) Microstructure analysis and thermal characteristics of NiTiHf shape memory alloy with different composition. Met Mater Int 27:767–778

Tong Y, Liu Y, Miao J, Zhao L (2005) Characterization of a nanocrystalline NiTiHf high temperature shape memory alloy thin film. Scr Mater 52:983–987

Evirgen A, Karaman I, Santamarta R, Pons J, Noebe RD (2015) Microstructural characterization and shape memory characteristics of the. Acta Mater 83:48–60

Babacan N, Bilal M, Hayrettin C, Liu J, Benafan O, Karaman I (2018) Effects of cold and warm rolling on the shape memory response of Ni 50 Ti 30 Hf 20 high-temperature shape memory alloy. Acta Mater 157:228

Zarinejad M, Liu Y, White TJ (2008) The crystal chemistry of martensite in NiTiHf shape memory alloys. Intermetallics 16:876–883

Elahinia M, Shayesteh Moghaddam N, Amerinatanzi A, Saedi S, Toker GP, Karaca H, Bigelow GS, Benafan O (2018) Additive manufacturing of NiTiHf high temperature shape memory alloy. Scr Mater 145:90

Atli KC, Karaman I, Noebe RD, Bigelow G, Gaydosh D (2015) Work production using the two-way shape memory effect in NiTi and a Ni-rich NiTiHf high-temperature shape memory alloy. Smart Mater Struct 24(12):12503

Karaca HE, Saghaian SM, Ded G, Tobe H, Basaran B, Maier HJ, Noebe RD, Chumlyakov YI (2013) Effects of nanoprecipitation on the shape memory and material properties of an Ni-rich NiTiHf high temperature shape memory alloy. Acta Mater 61:7422–7431

S Dhwanil, RD Noebe, AP Stebner (2013) Empirical Study of the Multiaxial Thermomechanical Behavior of NiTiHf Shape Memory Alloys.

Stebner AP, Bigelow GS, Yang J, Shukla DP, Saghaian SM, Rogers R, Garg A, Karaca HE, Chumlyakov Y, Bhattacharya K, Noebe RD (2014) ScienceDirect Transformation strains and temperatures of a nickel – titanium – hafnium high temperature shape memory alloy. Acta Mater 76:40–53

Ma J, Karaman I, Noebe RD, Ma J, Karaman I, Noebe RD (2021) High temperature shape memory alloys High temperature shape memory alloys. Acta Mater 218:1–8

Meng XL, Cai W, Chen F, Zhao LC (2006) Effect of aging on martensitic transformation and microstructure in Ni-rich TiNiHf shape memory alloy. Scr Mater 54:1599–1604

Karaca HE, Saghaian SM, Ded G, Tobe H, Basaran B, Maier HJ (2013) Effects of nanoprecipitation on the shape memory and material properties of an Ni-rich NiTiHf high temperature shape memory alloy. Acta Mater 61:7422–7431

Hite N, Sharar DJ, Trehern W, Umale T, Atli KC, Wilson AA, Leff AC, Karaman I (2021) NiTiHf shape memory alloys as phase change thermal storage materials. Acta Mater 218:117175

Yang F, Coughlin DR, Phillips PJ, Yang L, Devaraj A, Kovarik L, Noebe RD, Mills MJ (2013) Structure analysis of a precipitate phase in an Ni-rich high-temperature NiTiHf shape memory alloy. Acta Mater 61:3335–3346

Jain A, Goodson KE (2008) Measurement of the thermal conductivity and heat capacity of freestanding shape memory thin films using the 3ω method. J Heat Transfer 130:1–7

Sheskin A, Schwarz T, Yu Y, Zhang S, Abdellaoui L, Gault B, Cojocaru-Mirédin O, Scheu C, Raabe D, Wuttig M, Amouyal Y (2018) Tailoring Thermoelectric Transport Properties of Ag-Alloyed PbTe: Effects of Microstructure Evolution. ACS Appl Mater Interfaces 10:38994–39001

Tang W, Sundman B, Sandström R, Qiu C (1999) New modelling of the B2 phase and its associated martensitic transformation in the Ti-Ni system. Acta Mater 47:3457–3468

Khalil-Allafi J, Dlouhy A, Eggeler G (2002) Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations. Acta Mater 50:4255–4274

Evirgen A, Pons J, Karaman I, Santamarta R, Noebe RD (2018) H-Phase Precipitation and Martensitic Transformation in Ni-rich Ni–Ti–Hf and Ni–Ti-Zr High-Temperature Shape Memory Alloys. Shape Mem Superelasticity 4:85–92

Evirgen A, Basner F, Karaman I, Noebe RD, Pons J, Santamarta R (2012) Effect of aging on the martensitic transformation characteristics of a Ni-Rich NiTiHf high temperature shape memory alloy. Funct Mater Lett 5(4):12500

Zarnetta R, Takahashi R, Young ML, Savan A, Furuya Y, Thienhaus S, Maaß B, Rahim M, Frenzel J, Brunken H, Chu YS, Srivastava V, James RD, Takeuchi I, Eggeler G, Ludwig A (2010) Identification of quaternary shape memory alloys with near-zero thermal hysteresis and unprecedented functional stability. Adv Funct Mater 20:1917–1923

C Kittel (1986) Introduction to Solid State Physics John Wiley & Sons Inc, USA.

Ingale BD, Wei WC, Chang PC, Kuo YK, Wu SK (2011) Anomalous transport and thermal properties of NiTi and with Cu and Fe-doped shape memory alloys near the martensitic transition. J Appl Phys 110:113721

Amouyal Y (2014) Reducing Lattice Thermal Conductivity of the Thermoelectric Compound AgSbTe2 (P4/mmm) by Lanthanum Substitution: Computational and Experimental Approaches. J Electron Mater 43:3772–3779

Mason, SF (1979) Crystal structure determinations. Nature 282:346

Krug ME, Dunand DC, Seidman DN (2011) Effects of Li additions on precipitation-strengthened Al – Sc and Al – Sc – Yb alloys. Acta Mater 59:1700–1715

Lapovok R, Amouyal Y, Qi Y, Berner A (2020) & C corrosion Enhancement of electrical conductivity in aluminum single crystals by boron treatment in solid state. J Mater Sci 55:2564–2577

Prabhu TR (2017) Effects of ageing time on the mechanical and conductivity properties for various round bar diameters of AA 2219 Al alloy. Eng Sci Technol an Int J 20:133–142

Acknowledgements

We extend our acknowledgements to the Israel Science Foundation (ISF), Grant no. 1997/18. Partial support from the Technion Russell-Berrie Nanotechnology Institute (RBNI) is acknowledged, as well.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicting interests.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Keret-Klainer, M., Padan, R., Khoptiar, Y. et al. Tailoring thermal and electrical conductivities of a Ni-Ti-Hf-based shape memory alloy by microstructure design. J Mater Sci 57, 12107–12124 (2022). https://doi.org/10.1007/s10853-022-07383-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07383-6