Abstract

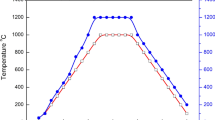

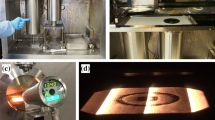

The temperature resistance of a magnetic powder core is determined by the organic resin in it, while the conventionally used phenolic resin and epoxy resin are sensitive to temperature. Herein, iron-based amorphous powder cores with heat-resisting polytetrafluoroethylene (PTFE) insulating layers were fabricated by processes of ball-milling mixing, cold pressing, simultaneously sintering, and annealing, and the effect of different PTFE contents on magnetic properties was analyzed. The PTFE played the roles of lubricant, insulating layer, and binder in the fabrication of magnetic powder cores. The high lubricity and deformability of PTFE well protected the amorphous powder from ball-milling or cold-pressing damage, making it feasible for mixing amorphous powder with PTFE. In the sintering process, melting PTFE could fill the air gaps among powders and endow the powder cores with available strength. The analysis of microstructure showed that the amorphous powders could be well coated by PTFE, and the tests of magnetic properties showed that the PTFE content had a fluctuating influence on the total core losses of the powder cores. Owing to the better microstructure homogeneity and more proper compositions, the powder cores with 2.4% and 3.6% mass fractions of PTFE show relatively high effective permeabilities above 25 under 100 kHz, and relatively low total core losses of 1448 and 1402 kW/m3 respectively under 100 kHz, 100 mT. Moreover, all the prepared magnetic powder cores exhibit superior DC-bias properties, the percentages of incremental permeability are as high as 83–90% under a direct magnetic field of 100 Oe.

Graphical abstract

Similar content being viewed by others

References

Chan T-Y, Lin S-T (1999) Injection molding of Fe–Ni–P composite powders prepared by electroless nickel plating and the magnetic properties of the sintered alloys. J Mater Process Tech 89:165–170

Hamler A, Goričan V, Šuštaršič B, Sirc A (2006) The use of soft magnetic composite materials in synchronous electric motor. J Magn Magn Mater 304:e816–e819

Liu Y, He S (2010) Development of high DC-bias Mn–Zn ferrite working at frequency higher than 3 MHz. J Alloy Compd 489:523–529

Zhou B, Dong Y, Liu L et al (2019) The core-shell structured Fe-based amorphous magnetic powder cores with excellent magnetic properties. Adv Powder Tech 30:1504–1512

Neamţu BV, Opriş A, Pszola P et al (2020) Preparation and characterisation of soft magnetic composites based on Fe fibres. J Mater Sci 55:1414–1424. https://doi.org/10.1007/s10853-019-04088-1

Raybould D, Tan K (1985) Factors affecting the magnetic properties of consolidated amorphous powder cores. J Mater Sci 20:2776–2786. https://doi.org/10.1007/BF00553039

Li Z, Dong Y, Pauly S et al (2017) Enhanced soft magnetic properties of Fe-based amorphous powder cores by longitude magnetic field annealing. J Alloy Compd 706:1–6

Saito T, Tsuruta H, Watanabe A, Ishimine T, Ueno T (2018) Pure-iron/iron-based-alloy hybrid soft magnetic powder cores compacted at ultra-high pressure. AIP Adv 8:047708

Liu M, Huang K, Liu L et al (2018) Fabrication and magnetic properties of novel Fe-based amorphous powder and corresponding powder cores. J Mater Sci-Mater El 29:6092–6097. https://doi.org/10.1007/s10854-018-8584-4

Ma R, Yu P (2021) The influences of matrix materials on the magnetic and mechanical properties of Fe78Si9B13 soft magnetic composites fabricated by injection molding. Mater Res Bull 139:111256

Schoppa A, Delarbre P (2014) Soft magnetic powder composites and potential applications in modern electric machines and devices. IEEE T Magn 50:1–4

Luan J, Sharma P, Yodoshi N, Zhang Y, Makino A (2016) Mechanically strong nanocrystalline Fe–Si–BP–Cu soft magnetic powder cores utilizing magnetic metallic glass as a binder. AIP Adv 6:055934

Jiang C, Li X, Ghosh SS, Zhao H, Shen Y, Long T (2020) Nanocrystalline powder cores for high-power high-frequency power electronics applications. IEEE Trans Power Electron 35:10821–10830

Shen B, Akiba M, Inoue A (2006) Excellent soft-ferromagnetic bulk glassy alloys with high saturation magnetization. Appl Phys Lett 88:131907

McHenry ME, Willard MA, Laughlin DE (1999) Amorphous and nanocrystalline materials for applications as soft magnets. Prog Mater Sci 44:291–433

Shi L, Qin X, Yao K (2020) Tailoring soft magnetic properties of Fe-based amorphous alloys through C addition. Prog Nat Sci 30:208–212

Nakahara S, Périgo E, Pittini-Yamada Y, De Hazan Y, Graule T (2010) Electric insulation of a FeSiBC soft magnetic amorphous powder by a wet chemical method: identification of the oxide layer and its thickness control. Acta Mater 58:5695–5703

Wang X, Lu C, Guo F, Lu Z, Li D, Zhou S (2012) New Fe-based amorphous compound powder cores with superior DC-bias properties and low loss characteristics. J Magn Magn Mater 324:2727–2730

Guo J, Dong Y, Man Q et al (2016) Fabrication of FeSiBPNb amorphous powder cores with high DC-bias and excellent soft magnetic properties. J Magn Magn Mater 401:432–435

Zhou B, Dong Y, Liu L, Chang L, Bi F, Wang X (2019) Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer. J Magn Magn Mater 474:1–8

Zhang Y, Dong Y, Zhou B et al (2020) Poly-para-xylylene enhanced Fe-based amorphous powder cores with improved soft magnetic properties via chemical vapor deposition. Mater Des 191:108650

Li B, Zheng Z, Yu H, Zeng D (2017) Improved permeability of Fe based amorphous magnetic powder cores by adding Permalloy. J Magn Magn Mater 438:138–143

Chang C, Dong Y, Liu M, Guo H, Xiao Q, Zhang Y (2018) Low core loss combined with high permeability for Fe-based amorphous powder cores produced by gas atomization powders. J Alloy Compd 766:959–963

Sun H, Wang C, Wang J, Yu M, Guo Z (2020) Fe-based amorphous powder cores with low core loss and high permeability fabricated using the core-shell structured magnetic flaky powders. J Magn Magn Mater 502:166548

Asim M, Saba N, Jawaid M, Nasir M, Pervaiz M, Alothman OY (2018) A review on phenolic resin and its composites. Curr Anal Chem 14(3):185–197

Matykiewicz D, Barczewski M, Michałowski S (2019) Basalt powder as an eco-friendly filler for epoxy composites: thermal and thermo-mechanical properties assessment. Compos Part B-Eng 164:272–279

Pan C, Kou K, Wu G, Zhang Y, Wang Y (2016) Fabrication and characterization of AlN/PTFE composites with low dielectric constant and high thermal stability for electronic packaging. J Mater Sci-Mater El 27(1):286–292

Rajesh S, Murali K, Priyadarsini V, Potty S, Ratheesh R (2009) Rutile filled PTFE composites for flexible microwave substrate applications. Mater Sci Eng: B 163(1):1–7

Makowiec ME, Blanchet TA (2017) Improved wear resistance of nanotube-and other carbon-filled PTFE composites. Wear 374:77–85

Shao W, Liu D, Cao T, Cheng H, Kuang J, Deng Y, Xie W (2021) Study on favorable comprehensive properties of superhydrophobic coating fabricated by polytetrafluoroethylene doped with graphene. Adv Compos Hybrid Ma 4(3):521–533

Sperati CA, Starkweather HW (1961) Fluorine-containing polymers. II. Polytetrafluoroethylene. Fortschritte Der Hochpolymeren-Forschung. Springer, Berlin, Heidelberg, pp 465–495

Dhanumalayan E, Joshi GM (2018) Performance properties and applications of polytetrafluoroethylene (PTFE)—a review. Adv Compos and Hybrid Ma 1:247–268

Puts GJ, Crouse P, Ameduri BM (2019) Polytetrafluoroethylene: synthesis and characterization of the original extreme polymer. Chem Rev 119:1763–1805

Zhao T, Chen C, Wu X, Zhang C, Volinsky AA, Hao J (2021) FeSiBCrC amorphous magnetic powder fabricated by gas-water combined atomization. J Alloy Compd 857:157991

Gamboni OC, Riul C, Billardon R, Bose Filho WW, Schmitt N, Canto RB (2016) On the formation of defects induced by air trapping during cold pressing of PTFE powder. Polymer 82:75–86

Chang C, Shen B, Inoue A (2006) FeNi-based bulk glassy alloys with superhigh mechanical strength and excellent soft-magnetic properties. Appl Phys Lett 89:051912

Xu K, Ling H, Li Q, Li J, Yao K, Guo S (2014) Effects of Co substitution for Fe on the glass forming ability and properties of Fe80P13C7 bulk metallic glasses. Intermetallics 51:53–58

Si J, Wu Y, Wang T, Liu Y, Hui X (2018) Composition-controlled active-passive transition and corrosion behavior of Fe–Cr(Mo)–Zr–B bulk amorphous steels. Appl Surf Sci 445:496–504

Si J, Du C, Wang T, Wu Y, Wang R, Hui X (2018) Glass formation and soft magnetic properties of novel Fe-rich Fe–B–Ti–Zr bulk metallic glasses. J Alloy Compd 741:542–548

Wang A, Zhao C, Men H et al (2015) Fe-based amorphous alloys for wide ribbon production with high Bs and outstanding amorphous forming ability. J Alloy Compd 630:209–213

Luborsky F, Walter J (1978) Stress relaxation in amorphous alloys. Mater Sci Eng 35:255–261

Neǐman M, Kovarskaya B, Golubenkova L, Strizhkova A, Levantovskaya I, Akutin M (1962) The thermal degradation of some epoxy resins. J Polym Sci 56(164):383–389

Snelling EC (1969) Soft ferrites: properties and applications. Butterworths

McLyman CWT (2004) Transformer and inductor design handbook. CRC Press

Zaspalis V, Tsakaloudi V, Kolenbrander M (2007) The effect of dopants on the incremental permeability of MnZn-ferrites. J Magn Magn Mater 313:29–36

Chang C, Guo J, Li Q, Zhou S, Liu M, Dong Y (2019) Improvement of soft magnetic properties of FeSiBPNb amorphous powder cores by addition of FeSi powder. J Alloy Compd 788:1177–1181

Wang C, Guo Z, Wang J, Sun H, Chen D, Chen W, Liu X (2020) Industry-oriented Fe-based amorphous soft magnetic composites with SiO2-coated layer by one-pot high-efficient synthesis method. J Magn Magn Mater 509:166924

Guo J, Dong Y, Man Q, Li Q, Chang C, Wang XM, Li RW (2016) Fabrication of FeSiBPNb amorphous powder cores with high DC-bias and excellent soft magnetic properties. J Magn Magn Mater 401:432–435

Huang K, Dong Y, Liu M, Ren J, Lu S, Zhao Z, Chang C, Wang X (2018) Controllable SiO2 coating layer of FeSiBPNb amorphous powder cores with excellent soft magnetic properties. J Iron Steel Res Int 25(6):624–629

Wang J, Guo Z, Zeng Q, Hang G, Xue Z, Chen D, Liang Z, Sun H (2020) Magnetic properties regulation and loss contribution analysis for Fe-based amorphous powder cores doped with micron-sized FeSi powders. J Magn Magn Mater 510:166931

Li Z, Dong Y, Pauly S, Chang C, Wei R, Li F, Wang XM (2017) Enhanced soft magnetic properties of Fe-based amorphous powder cores by longitude magnetic field annealing. J Alloy Compd 706:1–6

Acknowledgments

This work is supported by the financial supports from National Natural Science Foundation of China (Nos. 51801111 and 51871129) and Fundamental Research Funds for the Central Universities (22CX06022A).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Si, J., Ma, R., Wu, Y. et al. Microstructure and magnetic properties of novel powder cores composed of iron-based amorphous alloy and PTFE. J Mater Sci 57, 8154–8166 (2022). https://doi.org/10.1007/s10853-022-07199-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07199-4