Abstract

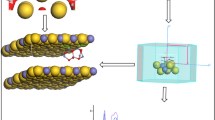

A new high-precision angular-dependent potential of the Ni–Pd system was obtained by fitting the experimental data and first-principles calculations. Then, the element segregation characteristics and thermal stability of Ni–Pd bimetallic nanoparticles were investigated by Monte Carlo method and molecular dynamics method. The results show that the chemical ordering pattern of PdxNi1 − x nanoparticle is the result of the competition of surface energy, strain energy, bond energy and interface energy. When a small amount of Pd atoms are substitutionally doped into the Ni nanoparticle, all the Pd atoms will be segregated on the surface and dispersed. The synergistic effect of Ni atoms and Pd atoms in the surface will improve the catalytic activity and carbon deposition resistance of PdxNi1 − x nanoparticle catalyst in methane dry reforming reaction. Increasing the doping amount of Pd atoms will gradually reduce the melting point of PdxNi1 − x nanoparticle, thereby reducing its sintering resistance.

Similar content being viewed by others

References

Yentekakis IV, Panagiotopoulou P, Artemakis G (2021) A review of recent efforts to promote dry reforming of methane (DRM) to syngas production via bimetallic catalyst formulations. Appl Catal B Environ 296:120210. https://doi.org/10.1016/j.apcatb.2021.120210

Abdulrasheed A, Jalil AA, Gambo Y, Ibrahim M, Hambali HU, Shahul Hamid MY (2019) A review on catalyst development for dry reforming of methane to syngas: recent advances. Renew Sust Energy Rev 108:175–193. https://doi.org/10.1016/j.rser.2019.03.054

Bian Z, Das S, Wai MH, Hongmanorom P, Kawi S (2017) A review on bimetallic nickel-based catalysts for CO2 reforming of methane. ChemPhysChem 18:3117–3134. https://doi.org/10.1002/cphc.201700529

Kathiraser Y, Oemar U, Saw ET, Li Z, Kawi S (2015) Kinetic and mechanistic aspects for CO2 reforming of methane over Ni based catalysts. Chem Eng J 278:62–78. https://doi.org/10.1016/j.cej.2014.11.143

Wang Z, Cao XM, Zhu J, Hu P (2014) Activity and coke formation of nickel and nickel carbide in dry reforming: a deactivation scheme from density functional theory. J Catal 311:469–480. https://doi.org/10.1016/j.jcat.2013.12.015

Pakhare D, Spivey J (2014) A review of dry (CO2) reforming of methane over noble metal catalysts. Chem Soc Rev 43:7813–7837. https://doi.org/10.1039/c3cs60395d

Barama S, Dupeyrat-Batiot C, Capron M, Bordes-Richard E, Bakhti-Mohammedi O (2009) Catalytic properties of Rh, Ni, Pd and Ce supported on Al-pillared montmorillonites in dry reforming of methane. Catal Today 141:385–392. https://doi.org/10.1016/j.cattod.2008.06.025

Singha RK, Shukla A, Sandupatla A, Deo G, Bal R (2017) Synthesis and catalytic activity of a Pd doped Ni–MgO catalyst for dry reforming of methane. J Mater Chem A 5:15688–15699. https://doi.org/10.1039/C7TA04452F

Steinhauer B, Kasireddy MR, Radnik J, Martin A (2009) Development of Ni–Pd bimetallic catalysts for the utilization of carbon dioxide and methane by dry reforming. Appl Catal A Gen 366:333–341. https://doi.org/10.1016/j.apcata.2009.07.021

Ma Q, Sun J, Gao X, Zhang J, Zhao T, Yoneyama Y, Tsubaki N (2016) Ordered mesoporous alumina-supported bimetallic Pd–Ni catalysts for methane dry reforming reaction. Catal Sci Technol 6:6542–6550. https://doi.org/10.1039/C6CY00841K

Pan C, Guo Z, Dai H, Ren R, Chu W (2020) Anti-sintering mesoporous Ni–Pd bimetallic catalysts for hydrogen production via dry reforming of methane. Int J Hydrog Energy 45:16133–16143. https://doi.org/10.1016/j.ijhydene.2020.04.066

Dang C, Luo J, Yang W, Li H, Cai W (2021) Low-temperature catalytic dry reforming of methane over Pd promoted Ni–CaO–Ca12Al14O33 multifunctional catalyst. Ind Eng Chem Res 60:18361–18372. https://doi.org/10.1021/acs.iecr.1c04010

Cheng H, Feng S, Tao W, Lu X, Yao W, Li G, Zhou Z (2014) Effects of noble metal-doping on Ni/La2O3–ZrO2 catalysts for dry reforming of coke oven gas. Int J Hydrog Energy 39:12604–12612. https://doi.org/10.1016/j.ijhydene.2014.06.120

Fan C, Zhu Y-A, Xu Y, Zhou Y, Zhou X-G, Chen D (2012) Origin of synergistic effect over Ni-based bimetallic surfaces: a density functional theory study. J Chem Phys 137:014703. https://doi.org/10.1063/1.4731811

Shang Z, Li S, Li L, Liu G, Liang X (2017) Highly active and stable alumina supported nickel nanoparticle catalysts for dry reforming of methane. Appl Catal B Environ 201:302–309. https://doi.org/10.1016/j.apcatb.2016.08.019

Mishin Y, Mehl MJ, Papaconstantopoulos DA (2005) Phase stability in the Fe–Ni system: investigation by first-principles calculations and atomistic simulations. Acta Mater 53:4029–4041. https://doi.org/10.1016/j.actamat.2005.05.001

Xia Y, Xiong Y, Lim B, Skrabalak SE (2009) Shape-controlled synthesis of metal nanocrystals: Simple chemistry meets complex physics? Angew Chem Int Edit 48:60–103. https://doi.org/10.1002/anie.200802248

Li L, xin Ma H, dong Jian X, Qian P, jing Su Y (2020) Degradation of the transition metal@Pt core–shell nanoparticle catalyst: a DFT study. Phys Chem Chem Phys 22:9467–9476. https://doi.org/10.1039/D0CP00888E

Metropolis N, Rosenbluth AW, Rosenbluth MN, Teller AH, Teller E (1953) Equation of state calculations by fast computing machines. J Chem Phys 21:1087–1092. https://doi.org/10.1063/1.1699114

Wang G, Xu Y-S, Qian P, Su Y-J (2019) The effects of size and shape on the structural and thermal stability of platinum nanoparticles. Comput Mater Sci 169:109090. https://doi.org/10.1016/j.commatsci.2019.109090

Mishin Y, Lozovoi AY (2006) Angular-dependent interatomic potential for tantalum. Acta Mater 54:5013–5026. https://doi.org/10.1016/j.actamat.2006.06.034

Purja Pun GP, Darling KA, Kecskes LJ, Mishin Y (2015) Angular-dependent interatomic potential for the Cu–Ta system and its application to structural stability of nano-crystalline alloys. Acta Mater 100:377–391. https://doi.org/10.1016/j.actamat.2015.08.052

Wang G, Xu Y, Qian P, Su Y (2021) ADP potential for the Au–Rh system and its application in element segregation of nanoparticles. Comput Mater Sci 186:110002. https://doi.org/10.1016/j.commatsci.2020.110002

Baskes MI (1987) Application of the embedded-atom method to covalent materials: a semiempirical potential for silicon. Phys Rev Lett 59:2666–2669. https://doi.org/10.1103/PhysRevLett.59.2666

Simmons G, Wang H (1971) Single crystal elastic constants and calculated aggregate properties: a handbook, 2nd edn. MIT Press, Cambridge

Wang G, Xu Y, Qian P, Su Y (2020) Vacancy concentration of films and nanoparticles. Comput Mater Sci 173:109416. https://doi.org/10.1016/j.commatsci.2019.109416

Rose JH, Smith JR, Guinea F, Ferrante J (1984) Universal features of the equation of state of metals. Phys Rev B 29:2963–2969. https://doi.org/10.1088/0953-8984/1/11/002

Predel F (2016) Phase equilibria, crystallographic and thermodynamic data of binary alloys, 1st edn. Springer, Berlin Heidelberg

Kresse G, Hafner J (1993) Ab initio molecular dynamics for liquid metals. Phys Rev B 47:558–561. https://doi.org/10.1103/PhysRevB.47.558

Kresse G, Furthmüller J (1996) Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B 54:11169–11186. https://doi.org/10.1103/physrevb.54.11169

Perdew JP, Chevary JA, Vosko SH, Jackson KA, Pederson MR, Singh DJ, Fiolhais C (1992) Atoms, molecules, solids, and surfaces: Applications of the generalized gradient approximation for exchange and correlation. Phys Rev B 46:6671–6687. https://doi.org/10.1103/PhysRevB.46.6671

Jeong G-U, Park CS, Do H-S, Park S-M, Lee B-J (2018) Second nearest-neighbor modified embedded-atom method interatomic potentials for the Pd-M (M = Al Co, Cu, Fe, Mo, Ni, Ti) binary systems. Calphad 62:172–186. https://doi.org/10.1016/j.calphad.2018.06.006

Samolyuk GD, Béland LK, Stocks GM, Stoller RE (2016) Electron–phonon coupling in Ni-based binary alloys with application to displacement cascade modeling. J Phys Condens Matter 28:175501. https://doi.org/10.1088/0953-8984/28/17/175501

Kittel C (2005) Introduction to solid state physics, 8th edn. Wiley, New York

Dinsdale AT (1991) SGTE data for pure elements. Calphad 15:317–425. https://doi.org/10.1007/10655491_1

Wycisk W, Feller-Kniepmeier M (1978) Quenching experiments in high purity Ni. J Nucl Mater 69–70:616–619. https://doi.org/10.1016/0022-3115(78)90293-3

Hirth JP, Lothe J (1982) Theory of dislocations, 2nd edn. Wiley, New York

Mezey L, Giber J (1982) The surface free energies of solid chemical elements: calculation from internal free enthalpies of atomization. Jpn J Appl Phys 21:1569–1571. https://doi.org/10.1143/jjap.21.1569

Foiles SM, Baskes MI, Daw MS (1986) Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys Rev B 33:7983–7991. https://doi.org/10.1103/PhysRevB.33.7983

Henkelman G, Uberuaga BP, Jónsson H (2000) A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J Chem Phys 113:9901–9904. https://doi.org/10.1063/1.1329672

Morris JR, Song X (2002) The melting lines of model systems calculated from coexistence simulations. J Chem Phys 116:9352–9358. https://doi.org/10.1063/1.1474581

Ferrando R, Jellinek J, Johnston RL (2008) Nanoalloys: from theory to applications of alloy clusters and nanoparticles. Chem Rev 108:845–910. https://doi.org/10.1021/cr040090g

Zaleska-Medynska A, Marchelek M, Diak M, Grabowska E (2016) Noble metal-based bimetallic nanoparticles: the effect of the structure on the optical, catalytic and photocatalytic properties. Adv Colloid Interface Sci 229:80–107. https://doi.org/10.1016/j.cis.2015.12.008

Deng L, Liu X, Zhang X, Wang L, Li W, Song M, Tang J, Deng H, Xiao S, Hu W (2019) Intrinsic strain-induced segregation in multiply twinned Cu–Pt icosahedra. Phys Chem Chem Phys 21:4802–4809. https://doi.org/10.1039/C8CP06327C

Xiao S, Hu W, Luo W, Wu Y, Li X, Deng H (2006) Size effect on alloying ability and phase stability of immiscible bimetallic nanoparticles. Eur Phys J B 54:479–484. https://doi.org/10.1140/epjb/e2007-00018-6

Deng L, Hu W, Deng H, Xiao S (2010) Surface segregation and structural features of bimetallic Au−Pt nanoparticles. J Phys Chem C 114:11026–11032. https://doi.org/10.1021/jp100194p

Martinez De La Hoz JM, Callejas Tovar R, Balbuena PB (2009) Size effect on the stability of Cu–Ag nanoalloys. Mol Simul 35:785–794. https://doi.org/10.1080/08927020902748673

Fischer F, Eich SM (2020) Analytic description of grain boundary segregation, tension, and formation energy in the copper–nickel system. Acta Mater 201:364–372. https://doi.org/10.1016/j.actamat.2020.09.039

Orera A, Wang F, Ferreiro-Vila E, Serrano-Zabaleta S, Larrañaga A, Laguna-Bercero MA, Dickey EC, Rivadulla F, Muñoz MC, Larrea Á (2020) Interfacial stability and ionic conductivity enhanced by dopant segregation in eutectic ceramics: the role of Gd segregation in doped CeO2/CoO and CeO2/NiO interfaces. J Mater Chem A 8:2591–2601. https://doi.org/10.1039/C9TA12315F

Guenther G, Guillon O (2014) Models of size-dependent nanoparticle melting tested on gold. J Mater Sci 49:7915–7932. https://doi.org/10.1007/s10853-014-8544-1

Zhu B, Creuze J, Mottet C, Legrand B, Guesmi H (2016) CO adsorption-induced surface segregation and formation of Pd chains on AuPd(100) alloy: density functional theory based Ising model and Monte Carlo simulations. J Phys Chem C 120:350–359. https://doi.org/10.1021/acs.jpcc.5b10158

Tao F, Grass Michael E, Zhang Y, Butcher Derek R, Renzas James R, Liu Z, Chung Jen Y, Mun Bongjin S, Salmeron M, Somorjai Gabor A (2008) Reaction-driven restructuring of Rh-Pd and Pt-Pd core-shell nanoparticles. Science 322:932–934. https://doi.org/10.1126/science.1164170

Acknowledgements

This study was supported by the National Key Research and Development Program of China (Grant No. 2021YFB3802100) and the Dean's fund of TianJin College, University of Science and Technology Beijing (Grant No. 2020YZJJ-KJ01).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, Y., Wang, G., Qian, P. et al. Element segregation and thermal stability of Ni–Pd nanoparticles. J Mater Sci 57, 7384–7399 (2022). https://doi.org/10.1007/s10853-022-07118-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07118-7