Abstract

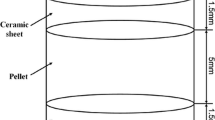

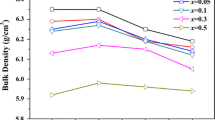

In the present work, we prepared (1−x)Mg(Ti0.95Sn0.05)O3–(x)BaTiO3 (0 ≤ x ≤ 0.1) solid-solutions via traditional solid-state reaction process and investigated their structural, optical, electrical, dielectric, and shielding properties. We report that these (1−x)Mg(Ti0.95Sn0.05)O3–(x)BaTiO3 compounds experienced structural phase transitions, wherein the tetragonal-structured BaTiO3 (space group P4mm) got transformed to monoclinic-structured Ba4Ti11O26 (space group C12/m1), and triclinic-structured Ba2Ti9O20 (space group P1). Interestingly, the Mg(Ti0.95Sn0.05)O3 showed no structural phase transition and was crystallized in its purest form without secondary phase formation. Additionally, the prepared compositions showed ten Raman active modes, and the relative density of all the samples exceeded 93.5%. The optical bandgap (Egap) values and DC conductivities of the samples were in the range of 3.82 eV–3.92 eV and 9.03 × 10−10 Sm−1–2.55 × 10−9 Sm−1, respectively. The composition 0.925 Mg(Ti0.95Sn0.05)O3–0.075BaTiO3 exhibited the best dielectric properties having relative permittivity (ɛr) of 19.69, loss tangent (tan δ) of 5.1 × 10−3, and temperature coefficient of resonant frequency (τf) of -8.5 ppm/°C at 1 MHz. In the Ku-band (12.4–18 GHz), this composition showed ɛr in the range of 14.62–15.49 and tan δ in the range of 2.85 × 10−2–5.89 × 10−2. An investigation of shielding properties in the Ku-band revealed that the prepared samples delivered average shielding effectiveness in the range of 5.98–6.65 dB. The prepared materials are proposed for microwave applications.

Similar content being viewed by others

References

Sebastian MT, Ubic R, Jantunen H (2015) Low-loss dielectric ceramic materials and their properties. Int Mater Rev 60:392–412. https://doi.org/10.1179/1743280415Y.0000000007

Reaney IM, Iddles D (2006) Microwave dielectric ceramics for resonators and filters in mobile phone networks. J Am Ceram Soc 89:2063–2072. https://doi.org/10.1111/j.1551-2916.2006.01025.X

Cava RJ (2001) Dielectric materials for applications in microwave communications. J Mater Chem 11:54–62. https://doi.org/10.1039/b003681l

Kawashima S, Nishida M, Ueda I, Ouchi H (1983) Ba(Zn1/3Ta2/3)O3 ceramics with low dielectric loss at microwave frequencies. J Am Ceram Soc 66:421–423. https://doi.org/10.1111/j.1151-2916.1983.tb10074.x

Scott RI, Thomas M, Hampson C (2003) Development of low cost, high performance Ba(Zn1/3Nb2/3O3) based materials for microwave resonator applications. J Eur Ceram Soc 23:2467–2471. https://doi.org/10.1016/S0955-2219(03)00134-1

Jancar B, Suvorov D, Valant M, Drazic G (2003) Characterization of CaTiO3–NdAlO3 dielectric ceramics. J Eur Ceram Soc 23:1391–1400. https://doi.org/10.1016/S0955-2219(02)00359-X

Viticoli M, Padeletti G, Kaciulis S et al (2005) Structural and dielectric properties of ZrTiO4 and Zr 0.8Sn0.2TiO4 deposited by pulsed laser deposition. Mater Sci Eng B Solid State Mater Adv Technol 118:87–91. https://doi.org/10.1016/j.mseb.2004.12.047

Ubic R, Reaney IM, Lee William E et al (1999) Properties of the microwave dielectric phase Ba6-3XNd8+2XTi18O54. Ferroelectrics 228:271–282. https://doi.org/10.1080/00150199908226141

Nomura S, Toyama K, Kaneta K (1982) Ba(mg1/3ta2/3)o3 ceramics with temperature-stable high dielectric constant and low microwave loss. Jpn J Appl Phys 21:L624–L626. https://doi.org/10.1143/JJAP.21.L624

Sun PH, Nakamura T, Shan YJ, et al (1998) Dielectric behavior of (1 − x)LaAlO3 − xSrTiO3 solid solution system at microwave frequencies. Jpn J Appl Phys Part 1 Regul Pap Short Notes Rev Pap 37:5625–5629. https://doi.org/10.1143/jjap.37.5625

Zheng J, Xing C, Yang Y et al (2020) Structure, infrared reflectivity spectra and microwave dielectric properties of a low-firing microwave dielectric ceramic Pr2Zr3(MoO4)9. J Alloys Compd 826:153893. https://doi.org/10.1016/j.jallcom.2020.153893

Guo HH, Zhou D, Du C et al (2020) Temperature stable Li2Ti0.75(Mg1/3Nb2/3)0.25O3-based microwave dielectric ceramics with low sintering temperature and ultra-low dielectric loss for dielectric resonator antenna applications. J Mater Chem C 8:4690–4700. https://doi.org/10.1039/d0tc00326c

Zhou D, Pang LX, Wang DW et al (2017) High permittivity and low loss microwave dielectrics suitable for 5G resonators and low temperature co-fired ceramic architecture. J Mater Chem C 5:10094–10098. https://doi.org/10.1039/c7tc03623j

Kim S, Khanal GP, Nam HW et al (2017) Structural and electrical characteristics of potential candidate lead-free BiFeO3–BaTiO3 piezoelectric ceramics. J Appl Phys 122:164105. https://doi.org/10.1063/1.4999375

González M, Pozuelo J, Baselga J (2018) Electromagnetic shielding materials in GHz range. Chem Rec 18:1000–1009. https://doi.org/10.1002/tcr.201700066

Abbasi H, Antunes M, Velasco JI (2019) Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding. Prog Mater Sci 103:319–373. https://doi.org/10.1016/j.pmatsci.2019.02.003

Zhao Z, Zhou X, Kou K, Wu H (2021) PVP-assisted transformation of ZIF-67 into cobalt layered double hydroxide/carbon fiber as electromagnetic wave absorber. Carbon N Y 173:80–90. https://doi.org/10.1016/j.carbon.2020.11.009

Zhao Z, Kou K, Zhang L, Wu H (2020) High efficiency electromagnetic wave absorber derived from transition metal layered double hydroxides. J Colloid Interface Sci 579:733–740. https://doi.org/10.1016/j.jcis.2020.06.123

Wakino K (1989) Recent development of dielectric resonator materials and filters in japan. Ferroelectrics 91:69–86. https://doi.org/10.1080/00150198908015730

Cho WW, Kakimoto KI, Ohsato H (2004) High-Q microwave dielectric SrTiO3-doped MgTiO3 materials with near-zero temperature coefficient of resonant frequency. Jpn J Appl Phys Part 1 Regul Pap Short Notes Rev Pap 43:6221–6224. https://doi.org/10.1143/JJAP.43.6221

Chen JY, Huang CL (2010) A new low-loss microwave dielectric using (Ca0.8Sr 0.2)TiO3-doped MgTiO3 ceramics. Mater Lett 64:2585–2588. https://doi.org/10.1016/j.matlet.2010.08.046

Huang CL, Bin CY, Tasi CF (2008) Influence of B2O3 additions to 0.8(Mg0.95Zn0.05)TiO3–0.2Ca0.61Nd0.26TiO3 ceramics on sintering behavior and microwave dielectric properties. J Alloys Compd 460:675–679. https://doi.org/10.1016/j.jallcom.2007.06.062

Sohn JH, Inaguma Y, Yoon SO et al (1994) Microwave dielectric characteristics of ilmenite-type titanates with high Q values. Jpn J Appl Phys 33:5466–5470. https://doi.org/10.1143/JJAP.33.5466

Huang CL, Liu SS (2007) Characterization of extremely low loss dielectrics (Mg 0.95Zn0.05)TiO3 at microwave frequency. Jpn J Appl Phys Part 1 Regul Pap Short Notes Rev Pap 46:283–285. https://doi.org/10.1143/JJAP.46.283

Gogoi P, Singh LR, Pamu D (2017) Characterization of Zn doped MgTiO3 ceramics: an approach for RF capacitor applications. J Mater Sci Mater Electron 28:11712–11721. https://doi.org/10.1007/s10854-017-6975-6

Tseng CF, Hsu CH (2009) A new compound with ultra low dielectric loss at microwave frequencies. J Am Ceram Soc 92:1149–1152. https://doi.org/10.1111/j.1551-2916.2009.03046.x

Tseng CF (2008) Microwave dielectric properties of a new ultra low loss pervoskite ceramic. J Am Ceram Soc 91:4125–4128. https://doi.org/10.1111/j.1551-2916.2008.02779.x

Ichinose N, Yamamoto H (1997) Effect of additives on microwave dielectric properties in low-temperature firing (Mg, Ca)TiO3 based ceramics. Ferroelectrics 201:255–262. https://doi.org/10.1080/00150199708228375

Huang CL, Weng MH (2001) Improved high Q value of MgTiO3–CaTiO3 microwave dielectric ceramics at low sintering temperature. Mater Res Bull 36:2741–2750. https://doi.org/10.1016/S0025-5408(01)00752-8

Seabra MP, Avdeev M, Ferreira VM et al (2004) Structure–property relations in x BaTiO3-(1–x)La(Mg1/2Ti1/2)O3 solid solutions. J Am Ceram Soc 87:584–590. https://doi.org/10.1111/j.1551-2916.2004.00584.x

Ogihara H, Randall CA, Trolier-Mckinstry S (2009) High-energy density capacitors utilizing 0.7 baTiO3–0.3 BiScO3 ceramics. J Am Ceram Soc 92:1719–1724. https://doi.org/10.1111/j.1551-2916.2009.03104.x

Kumar N, Ionin A, Ansell T et al (2015) Multilayer ceramic capacitors based on relaxor BaTiO3–Bi(Zn1/2Ti1/2)O3 for temperature stable and high energy density capacitor applications. Appl Phys Lett 106:252901. https://doi.org/10.1063/1.4922947

Wang T, Jin L, Li C et al (2014) Relaxor ferroelectric BaTiO3–Bi(Mg2/3Nb1/3)O3 ceramics for energy storage application. J Am Ceram Soc 98:559–566. https://doi.org/10.1111/jace.13325

Karaki T, Yan K, Miyamoto T, Adachi M (2007) Lead-free piezoelectric ceramics with large dielectric and piezoelectric constants manufactured from BaTiO3 nano-powder. Jpn J Appl Phys Part 2 Lett 46:L97–L98. https://doi.org/10.1143/JJAP.46.L97

Takahashi H, Ayusawa K, Sakamoto N (1997) Microwave dielectric properties of Ba(Mg1/2W1/2)O3-BaTiO3 ceramics. Jpn J Appl Phys Part 1 Regul Pap Short Notes Rev Pap 36:5597–5599. https://doi.org/10.1143/jjap.36.5597

Buscaglia MT, Bassoli M, Buscaglia V, Alessio R (2005) Solid-state synthesis of ultrafine BaTiO3 powders from nanocrystalline BaCO3 and TiO2. J Am Ceram Soc 88:2374–2379. https://doi.org/10.1111/j.1551-2916.2005.00451.x

Upadhyay SK, Reddy VR, Lakshmi N (2013) Study of (1–x) BaTiO3-x Ni0.5Zn0.5Fe2O4 (x = 5, 10 and 15%) magneto-electric ceramic composites. J Asian Ceram Soc 1:346–350. https://doi.org/10.1016/j.jascer.2013.10.001

Singh J, Bahel S (2020) Synthesis of single phase MgTiO3 and influence of Sn4+ substitution on its structural, dielectric and electrical properties. J Alloys Compd 816:152679. https://doi.org/10.1016/j.jallcom.2019.152679

Singh J, Bahel S (2020) (BaxMg1-x) (Ti0.95Sn0.05)O3 (x = 0.025, 0.05, 0.075 and 0.1) solid solutions as effective Ku-band (12.4–18 GHz) shielders. Ceram Int 46:15206–15213. https://doi.org/10.1016/j.ceramint.2020.03.057

Singh J, Bahel S (2019) Structural and dielectric properties of (BaxMg1−x)(Ti0.95Sn0.05)O3 (x = 0.025, 0.05, 0.075 and 0.1) solid solutions. J Mater Sci Mater Electron 30:6500–6506. https://doi.org/10.1007/s10854-019-00955-4

Roisnel T, Rodríguez-Carvajal J (2001) WinPLOTR: a windows tool for powder diffraction pattern analysis. In: Materials science forum. Trans Tech Publications Ltd, pp 118–123

Rietveld HM (1969) A profile refinement method for nuclear and magnetic structures. J Appl Crystallogr 2:65–71. https://doi.org/10.1107/s0021889869006558

Young R (1993) The rietveld method

Momma K, Izumi F (2008) VESTA: a three-dimensional visualization system for electronic and structural analysis. J Appl Crystallogr 41:653–658. https://doi.org/10.1107/S0021889808012016

Rueden CT, Schindelin J, Hiner MC et al (2017) Image J2: ImageJ for the next generation of scientific image data. BMC Bioinform 18:529. https://doi.org/10.1186/s12859-017-1934-z

Shannon RD (1976) Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr Sect A 32:751–767. https://doi.org/10.1107/S0567739476001551

Wechsler BA, Von Dreele RB (1989) Structure refinements of Mg2TiO4, MgTiO3 and MgTi2O5 by time-of-flight neutron powder diffraction. Acta Crystallogr Sect B 45:542–549. https://doi.org/10.1107/S010876818900786X

Wäsche R, Denner W, Schulz H (1981) Influence of high hydrostatic pressure on the crystal structure of barium titanate (BaTiO3). Mater Res Bull 16:497–500. https://doi.org/10.1016/0025-5408(81)90113-6

Fallon GD, Gatehouse BM (1983) The crystal structure of Ba2Ti9O20: a hollandite related compound. J Solid State Chem 49:59–64. https://doi.org/10.1016/0022-4596(83)90216-5

Hofmeister W, Tillmanns E (1978) Ba2Ti5.5O13: Ladungsausgleich durch statistische Unterbesetzung

Kholodkova AA, Danchevskaya MN, Ivakin YD et al (2016) Crystalline barium titanate synthesized in sub- and supercritical water. J Supercrit Fluids 117:194–202. https://doi.org/10.1016/j.supflu.2016.06.018

Wang CH, Jing XP, Feng W, Lu J (2008) Assignment of Raman-active vibrational modes of MgTiO3. J Appl Phys 104:034112. https://doi.org/10.1063/1.2966717

Shannon RD (1993) Dielectric polarizabilities of ions in oxides and fluorides. J Appl Phys 73:348–366. https://doi.org/10.1063/1.353856

Angadi B, Jali VM, Lagare MT et al (2002) Synthesis and thermal expansion hysteresis of Ca1-xSrxZr4P6O24. Bull Mater Sci 25:191–196. https://doi.org/10.1007/BF02711152

Jo HJ, Kim ES (2017) Dependence of microwave dielectric properties on the complex substitution for Ti-site of MgTiO3 ceramics. Ceram Int 43:S326–S333. https://doi.org/10.1016/j.ceramint.2017.05.302

Jo HJ, Kim ES (2016) Enhanced quality factor of MgTiO3 ceramics by isovalent Ti-site substitution. Ceram Int 42:5479–5486. https://doi.org/10.1016/j.ceramint.2015.12.096

Gouveia AF, Sczancoski JC, Ferrer MM et al (2014) Experimental and theoretical investigations of electronic structure and photoluminescence properties of β-Ag2MoO4 microcrystals. Inorg Chem 53:5589–5599. https://doi.org/10.1021/ic500335x

Pal U (2007) Use of diffuse reflectance spectroscopy for optical characterization of un-supported nanostructures. Rev Mex Física 53:18–22

Tauc J, Grigorovici R, Vancu A (1966) Optical properties and electronic structure of amorphous germanium. Phys Status Solidi 15:627–637. https://doi.org/10.1002/pssb.19660150224

Ferri EAV, Sczancoski JC, Cavalcante LS et al (2009) Photoluminescence behavior in MgTiO3 powders with vacancy/distorted clusters and octahedral tilting. Mater Chem Phys 117:192–198. https://doi.org/10.1016/j.matchemphys.2009.05.042

Santhosh Kumar T, Bhuyan RK, Pamu D (2013) Effect of post annealing on structural, optical and dielectric properties of MgTiO 3 thin films deposited by RF magnetron sputtering. Appl Surf Sci 264:184–190. https://doi.org/10.1016/j.apsusc.2012.09.168

Khobragade N, Sinha E, Rout SK, Kar M (2013) Structural, optical and microwave dielectric properties of Sr 1−xCaxWO4 ceramics prepared by the solid state reaction route. Ceram Int 39:9627–9635. https://doi.org/10.1016/j.ceramint.2013.05.084

Dakin TW (2006) Conduction and polarization mechanisms and trends in dielectric. IEEE Electr Insul Mag 22:11–28. https://doi.org/10.1109/MEI.2006.1705854

Maxwell JC (1929) Electricity and magnetism

Koops CG (1951) On the dispersion of resistivity and dielectric constant of some semiconductors at audiofrequencies. Phys Rev 83:121–124. https://doi.org/10.1103/PhysRev.83.121

Yoon SH, Kim DW, Cho SY, Hong KS (2006) Investigation of the relations between structure and microwave dielectric properties of divalent metal tungstate compounds. J Eur Ceram Soc 26:2051–2054. https://doi.org/10.1016/j.jeurceramsoc.2005.09.058

Li C, Yin C, Deng M et al (2020) Tunable microwave dielectric properties in SrO-V2O5 system through compositional modulation. J Am Ceram Soc 103:2315–2321. https://doi.org/10.1111/jace.16955

Singh J, Bahel S (2021) Structural, vibrational, optical, dielectric, and shielding characteristics of (1 − x)Mg(Ti0.95Sn0.05)O3–(x)SrTiO3 (0 ≤ x ≤ 0.1) ceramics. Mater Res Bull 139:111245–13. https://doi.org/10.1016/j.materresbull.2021.111245

Zhang Y, Pan T, Yang Z (2020) Flexible polyethylene terephthalate/polyaniline composite paper with bending durability and effective electromagnetic shielding performance. Chem Eng J 389:124433–13. https://doi.org/10.1016/j.cej.2020.124433

Wang G, Liao X, Yang J et al (2019) Frequency-selective and tunable electromagnetic shielding effectiveness via the sandwich structure of silicone rubber/graphene composite. Compos Sci Technol 184:107847–9. https://doi.org/10.1016/j.compscitech.2019.107847

Acknowledgements

The author, Jasdeep Singh, gratefully acknowledges the university grants commission (UGC) India for providing fellowship under the senior research fellowship (SRF) scheme.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest associated with this publication.

Additional information

Handling Editor: Till Froemling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Singh, J., Bahel, S. Synthesis and characterization of temperature stable low-loss (1−x)Mg(Ti0.95Sn0.05)O3–(x)BaTiO3 (0 ≤ x ≤ 0.1) ceramics for microwave applications. J Mater Sci 56, 10947–10964 (2021). https://doi.org/10.1007/s10853-021-05996-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05996-x