Abstract

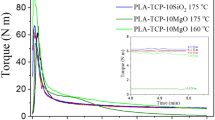

As known, the poor toughness of Polylactic acid (PLA) limits its further application, especially as a bone implant withstanding complex loadings. Blending PLA with Poly (ε-caprolactone) (PCL) under the action of compatibilizers is a proven method to improve the toughness of PLA, while the excess compatibilizers is hard to remove and easy to contaminate the matrix material. This study employed a molecular dynamics simulation combining experimental testing method to investigate the miscibility, mechanical properties and printability of PLA/PCL blends at different compositions without adding any compatibilizers, so as to obtain an ideal PLA/PCL filament for FDM printing bone scaffolds. Results of binding energy distribution and intermolecular interaction show that the miscibility of PLA and PCL is not very good, only the blend of 9PLA/1PCL is miscible. The calculated static mechanical properties and tensile testing results indicate the stiffness or hardness of blends decrease with the addition of PCL, while the toughness firstly increases and then decreases with the introduction of PCL, and the blend of 9PLA/1PCL possesses the best ductility and toughness. Moreover, the results of surface morphology confirm the miscible of 9PLA/1PCL blend and explain why the tensile properties of 9PLA/1PCL is the best, a better miscibility indicating better mechanical properties. Finally, the results of printability indicates that, due to the fluidity of PCL, the printability of blend becomes worse with the increase of PCL content, and the blend of 9PLA/1PCL possesses a relatively good printability. This work provides a practical guidance to the design of PLA/PCL blend filament for FDM printing bone scaffolds.

Graphical Abstract

Similar content being viewed by others

References

Wang GL, Zhang DM, Wan GP, Li B, Zhao GQ (2019) Glass fiber reinforced PLA composite with enhanced mechanical properties, thermal behavior, and foaming ability. Polymer 181:121803

da Silva D, Kaduri M, Poley M, Adir O, Krinsky N, Shainsky-Roitman J, Schroeder A (2018) Biocompatibility, biodegradation and excretion of polylactic acid (PLA) in medical implants and theranostic systems. Chem Eng J 340:9–14

Saez-Orviz S, Marcet I, Weng SH, Rendueles M, Rendueles M, Diaz M (2020) PLA nanoparticles loaded with thymol to improve its incorporation into gelatine films. J Food Eng 269:109751

Wu D, Spanou A, Diez-Escudero A, Persson C (2020) 3D-printed PLA/HA composite structures as synthetic trabecular bone: a feasibility study using fused deposition modeling. J Mech Behav Biomed Mater 103:103608

Chen XB, Gao CH, Jiang JW, Wu YP, Zhu PZ, Chen G (2019) 3D printed porous PLA/nHA composite scaffolds with enhanced osteogenesis and osteoconductivity in vivo for bone regeneration. Biomed Mater 14(6):065003

Xiao W, Zaeem MA, Li GD, Bal BS, Rahaman MN (2017) Tough and strong porous bioactive glass-PLA composites for structural bone repair. J Mater Sci 52(15):9039–9054. https://doi.org/10.1007/s10853-017-0777-3

Gremare A, Guduric V, Bareille R, Heroguez V, Latour S, L’heureux N, Fricain JC, Catros S, Le Nihouannen D, (2018) Characterization of printed PLA scaffolds for bone tissue engineering. J Biomed Mater Res, Part A 106(4):887–894

Gregor A, Filova E, Novak M, Kronek J, Chlup H, Buzgo M, Blahnova V, Lukasova V, Bartos M, Necas A, Hosek J (2017) Designing of PLA scaffolds for bone tissue replacement fabricated by ordinary commercial 3D printer. J Biol Eng 11:31

Singh D, Babbar A, Jain V, Gupta D, Saxena S, Dwibedi V (2019) Synthesis, characterization, and bioactivity investigation of biomimetic biodegradable PLA scaffold fabricated by fused filament fabrication process. J Brazilian Soc Mech Sci Eng 41(3):121

Oladapo BI, Daniyan IA, Ikumapayi OM, Malachi OB, Olaoluwa B, Malachi IO (2020) Microanalysis of hybrid characterization of PLA/cHA polymer scaffolds for bone regeneration. Polym Testing 83:106341

Li XY, Wang Y, Wang ZG, Qi YX, Li LL, Zhang PB, Chen XS, Huang YB (2018) Composite PLA/PEG/nHA/dexamethasone scaffold prepared by 3d printing for bone regeneration. Macromol Biosci 18(6):1800068

Wei QH, Cai XX, Guo YH, Wang GW, Guo Y, Lei MJ, Song Y, Zhang YF, Wang YN (2019) Atomic-scale and experimental investigation on the micro-structures and mechanical properties of PLA blending with CMC for additive manufacturing. Mater Des 183:108158

Wang M, Favi P, Cheng XQ, Golshan NH, Ziemer KS, Keidar M, Webster TS (2016) Cold atmospheric plasma (CAP) surface nanomodified 3D printed polylactic acid (PLA) scaffolds for bone regeneration. Acta Biomater 46:256–265

Mohsenimehr S, Khani MR, Fani N, Eslaminejad MRB, Shokri B, Ghassami A (2020) Surface modification of PLA scaffold using radio frequency (RF) nitrogen plasma in tissue engineering application. Surface Topography-Metrology and Properties 8(1):015012

Pon-On w, Suntornsaratoon P, Charoenphandhu N, Thongbunchoo J, Krishnamra N, Tang IM (2019) Synthesis and investigations of mineral ions-loaded apatite from fish scale and PLA/chitosan composite for bone scaffolds. Materials Letters 221: 143-146.

Sharma D, Satapathy BK. Performance evaluation of electrospun nanofibrous mats of polylactic acid (PLA)/poly (e-caprolactone) (PCL) blends. Mat Today Proc 19: 188–195.

Zhu B, Wang YM, Liu H, Ying J, Liu CT, Shen CY (2020) Effects of interface interaction and microphase dispersion on the mechanical properties of PCL/PLA/MMT nanocomposites visualized by nanomechanical mapping. Compos Sci Technol 190:108048

Lin YW, Shen HY, Xu GH, Zhang LC, Fu JZ, Deng XL (2018) Single-layer temperature-adjusting transition method to improve the bond strength of 3D-printed PCL/PLA parts. Compos Part A-Appl Sci Manufact 115:22–30

Yao QQ, Cosme JGL, Xu T, Miszuk JM, Picciani PHS, Fong H, Sun HL (2017) Three dimensional electrospun PCL/PLA blend nanofibrous scaffolds with significantly improved stem cells osteogenic differentiation and cranial bone formation. Biomaterials 115:115–127

Finotti PFM, Costa LC, Chinelatto MA (2016) Effect of the chemical structure of compatibilizers on the thermal, mechanical and morphological properties of immiscible pla/pcl blends. Macromol Symposia 368:24–29

Al-Mulla EAJ, Ibrahim NAB, Shameli K, Bin Ahmad M, Yunus WMZW (2014) Effect of epoxidized palm oil on the mechanical and morphological properties of a PLA-PCL blend. Res Chem Intermed 40(2):689–698

Wang LX, Wang DF, Zhou YP, Zhang YT, Li Q, Shen CY (2019) Fabrication of open-porous PCL/PLA tissue engineering scaffolds and the relationship of foaming process, morphology, and mechanical behavior. Polym Adv Technol 30:2539–2548

Fortelny I, Ujcic A, Fambri L, Slouf M (2019) Phase structure, compatibility, and toughness of pla/pcl blends: a review. Front Mat 6:206

Luyt AS, Gasmi S (2016) Influence of blending and blend morphology on the thermal properties and crystallization behaviour of PLA and PCL in PLA/PCL blends. J Mater Sci 51:4670–4681. https://doi.org/10.1007/s10853-016-9784-z

Mason JA, Sperling LH (1976) Polymer blends and composites. New York Plenum Press, New York

Yang JQ, Gong XD, Wang GX (2015) Compatibility and mechanical properties of BAMO-AMMO/DIANP composites: a molecular dynamics simulation. Comput Mater Sci 102:1–6

Wei QH, Wang YN, Chai WH, Wang T, Zhang YF (2016) Effects of composition ratio on the properties of poly(vinyl alcohol)/poly(acrylic acid) blend membrane: a molecular dynamics simulation study. Mater Des 89:848–855

Materials Studio Version 8.0 (2014) Accelrys Inc., San Diego, CA.

Mark JE (1999) Polymer Data Handbook. Oxford University Press.

Karayiannis NC, Mavrantzas VG, Theodorou DN (2004) Detailed Atomistic Simulation of the Segmental Dynamics and Barrier Properties of Amorphous Poly(ethylene terephthalate) and Poly(ethylene isophthalate). Macromolecules 37:2978–2995

Kim B, Choi J, Yang S, Yu S, Cho M (2015) Influence of crosslink density on the interfacial characteristics of epoxy nanocomposites. Polymer 60:186–197

Takhulee A, Takahashi Y, Vao-soongnern V (2017) Molecular simulation and experimental studies of the miscibility of polylactic acid/polyethylene glycol blends. J Polym Res 24:8

Sun H (1998) COMPASS: An ab initio force-field optimized for condensed-phase applications overview with details on alkane and benzene compounds. J Phys Chem B 102:7338–7364

Andersen HC (1980) Molecular dynamics simulations at constant pressure and/or temperature. J Chem Phys 72:2384–2393

Wei QH, Wang GW, Lei MJ, Guo Y, Song Y, Lu TL, Wang YN (2019) Multi-scale investigation on the phase miscibility of polylactic acid/o-carboxymethyl chitosan blends. Polymer 176:159–167

Fan CF, Olafson BD, Blanco M, Hsu SL (1992) Application of molecular simulation to derive phase diagrams of binary mixtures. Macromolecules 25:3667–3676

Blanco M (1991) Molecular silverware. I. General solutions to excluded volume constrained problems. J Comput Chem 12(2): 237–247.

Oh SY, Bae YC (2011) Correlation of thermodynamic modeling and molecular simulations for liquid-liquid equilibrium of ternary polymer mixtures based on a phenomenological scaling method. Fluid Phase Equilib 307(2):202–207

Sun H, Xiao AJ, Yu B, Bhat G, Zhu FC (2017) Effect of PCL and Compatibilizer on the Tensile and Barrier Properties of PLA/PCL Films. Polymer-Korea 41:181–188

Glova AD, Falkovich SG, Dmitrienko DI, Lyulin AV, Larin SV, Nazarychev VM, Karttunen M, Lyulin SV (2018) Scale-dependent miscibility of polylactide and polyhydroxybutyrate: molecular dynamics simulations. Macromolecules 51(2):552–563

Akten ED, Mattice WL (2001) Monte carlo simulation of head-to-head, tail-to-tail polypropylene and its mixing with polyethylene in the melt. Macromolecules 34:3389–3395

Weiner JH (2002) Statistical Mechanics of Elasticity. Dover Publications Inc, New York

Watt JP, Davies GF, O’Connell RJ (1976) The elastic properties of composite materials. Rev Geophys 14:541–563

Jin RH, Hua YQ (2000) Polymer Physics, 2nd edn. Chemical Industry Press, Beijing ((in Chinese))

Qiu L, Xiao HM (2009) Molecular dynamics study of binding energies, mechanical properties, and detonation performances of bicyclo-HMX-based PBXs. J Hazard Mater 164:329–336

Acknowledgements

This project was sponsored by the National Natural Science Foundation of China (Grant No. 51905438), The National Key Research and Development Program of China (Grant No. 2019QY(Y)0502), the Fundamental Research Funds for the Central Universities (Grant No. 31020190502009), the Innovation Platform of Biofabrication (Grant No.17SF0002), and the Key Research and Development program of Shaanxi Province (Grant No. 2018ZDXM-GY-133). We would like to thank the Analytical & Testing Center of Northwestern Polytechnical University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Yaroslava Yingling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, Q., Sun, D., Zhang, K. et al. Research on the miscibility, mechanical properties and printability of polylactic acid/poly (ε-caprolactone) blends: insights from molecular dynamics simulation and experiments. J Mater Sci 56, 9754–9768 (2021). https://doi.org/10.1007/s10853-021-05918-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05918-x