Abstract

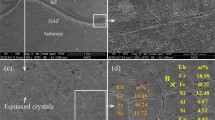

The microstructure, microhardness and corrosion resistance of laser cladding Al2O3@Ni composite coating were investigated. The Al2O3@Ni core–shell metal-ceramic powders synthesized via electroless plating method were used as laser cladding materials. According to the results of scanning electron microscopy and energy dispersive spectrometer, the microstructure of the Al2O3@Ni composite coating gradually transitioned from columnar crystal to cellular crystal and equiaxed crystal along the bottom to the surface. Furthermore, the Ni particles and Al2O3 particles separated when laser heating, then formed Ni metallurgical bonding layer and Al2O3 ceramic layer, respectively. The microhardness of Al2O3@Ni composite coating was up to 917.0 HV, which was about 5.7 times that of 304 stainless steel. In addition, immersion and electrochemical tests revealed that Al2O3@Ni composite coating exhibited excellent corrosion resistance compared with 304 stainless steel. The corrosion current density of the Al2O3@Ni composite coating (36.493 μA cm−2) was about 67.0% lower than that of 304 stainless steel (110.592 μA cm−2). Meanwhile, the corrosion mechanism of Al2O3@Ni composite coating was revealed. Dense Al2O3@Ni composite coating can inhibit the penetration of Cl− and H+, making the corrosion reaction difficult to occur.

Similar content being viewed by others

References

Jiménez-Come MJ, Turias IJ, Trujillo FJ (2014) An automatic pitting corrosion detection approach for 316 L stainless steel. Mater Des 56:642–648. https://doi.org/10.1016/j.matdes.2013.11.045

Hu CL, Xia S, Li H, Liu TG, Zhou BX, Chen WJ, Wang N (2011) Improving the intergranular corrosion resistance of 304 stainless steel by grain boundary network control. Corros Sci 53:1880–1886. https://doi.org/10.1016/j.corsci.2011.02.005

Xing XG, Wang HF, Lu PN, Han ZJ (2016) Influence of rare earths on electrochemical corrosion and wear resistance of RE–Cr/Ti pack coatings on cemented 304 stainless steel. Surf Coat Technol 291:151–160. https://doi.org/10.1016/j.surfcoat.2016.02.001

Kim J, Sankara Narayanan TSN, Park HW (2020) Reducing the pitting susceptibility of AISI 304 stainless steel using a hybrid treatment of high-power diode laser and large pulsed electron beam irradiation. Surf Coat Technol 381:125124. https://doi.org/10.1016/j.surfcoat.2019.125124

Albrimi YA, Addi AA, Douch J, Souto RM, Hamdani M (2015) Inhibition of the pitting corrosion of 304 stainless steel in 0.5 M hydrochloric acid solution by heptamolybdate ions. Corros Sci 90:522–528. https://doi.org/10.1016/j.corsci.2014.10.023

Sun Y (2013) Sliding wear behaviour of surfacemechanical attrition treated AISI 304 stainless steel. Tribol Int 57:67–75. https://doi.org/10.1016/j.triboint.2012.07.015

Tsujikawa M, Noguchi S, Yamauchi N, Ueda N, Sone T (2007) Effect of molybdenum on hardness of low-temperature plasma carburized austenitic stainless steel. Surf Coat Technol 201:5102–5107. https://doi.org/10.1016/j.surfcoat.2006.07.127

Stewart JA, Spearot DE (2017) Phase-field simulations of microstructure evolution during physical vapor deposition of single-phase thin films. Comput Mater Sci 131:170–177. https://doi.org/10.1016/j.commatsci.2017.01.034

Chaitoglou S, Bertran E (2017) Effect of temperature on graphene grown by chemical vapor deposition. J Mater Sci 52:8348–8356. https://doi.org/10.1007/s10853-017-1054-1

MacDonald D, Fernandez R, Delloro F, Jodoin B (2017) Cold spraying of arm strong process titanium powder for additive manufacturing. J Therm Spray Technol 26:598–609. https://doi.org/10.1007/s11666-016-0489-2

Hu M, Tang JC, Chen XG, Ye N, Zhao XY, Xu MM (2020) Microstructure and properties of WC-12Co composite coatings prepared by laser cladding. Trans Nonferr Metal Soc 30:1017–1030. https://doi.org/10.1016/S1003-6326(20)65273-6

Zhang MY, Li M, Wang SF, Chi J, Ren LS, Fang M, Zhou C (2020) Enhanced wear resistance and new insight into microstructure evolution of in situ (Ti, Nb) C reinforced 316 L stainless steel matrix prepared via laser cladding. Opt Laser Eng 128:106043. https://doi.org/10.1016/j.optlaseng.2020.106043

Aguilar-Hurtado JY, Vargas-Uscategui A, Paredes-Gil K, Palma-Hillerns R, Tobar MJ, Amado JM (2020) Boron addition in a non-equiatomic Fe50Mn30Co10Cr10 alloy manufactured by laser cladding: microstructure and wear abrasive resistance. Appl Surf Sci 515:146084. https://doi.org/10.1016/j.apsusc.2020.146084

Dong TS, Liu M, Feng Y, Li GL, Li XB (2020) Microstructure and properties of a wear resistant Al–25Si–4Cu–1 Mg coating prepared by supersonic plasma spraying. Int J Min Met Mater 27:1287–1294. https://doi.org/10.1007/s12613-019-1950-2

Liu CS, Wei DD, Xu RS, Mai YJ, Zhang LY, Jie XH (2020) Electroplated Co-Ni/WS2 composite coating with excellent tribological and anticorrosion performance. Tribol Trans. https://doi.org/10.1080/10402004.2020.1759742

Zhou SF, Dai XQ (2010) Laser induction hybrid rapid cladding of WC particles reinforced NiCrBSi composite coatings. Appl Surf Sci 256:4708–4714. https://doi.org/10.1016/j.apsusc.2010.02.078

Cao YB, Ren HT, Hu CS, Meng QX, Liu Q (2015) In-situ formation behavior of NbC-reinforced Fe-based laser cladding coatings. Mater Lett 147:61–63. https://doi.org/10.1016/j.matlet.2015.02.026

Wang CL, Gao Y, Wang R, Wei DQ, Cai M, Fu YK (2018) Microstructure of laser-clad Ni60 cladding layers added with different amounts of rare-earth oxides on 6063 Al alloys. J Alloy Compd 740:1099–1107. https://doi.org/10.1016/j.jallcom.2018.01.061

Tanaike O, Noguchi Y, Hayashi S, Sugai I, Niwa E, Iijima T, Ebina T (2020) Study on the cross-sectional microstructure of a thin ceramic coating on stainless steel surface fabricated by the application and calcination of an aqueous clay mineral paste. Appl Clay Sci 193:105665. https://doi.org/10.1016/j.clay.2020.105665

Xu CH, Feng YM, Zhang RB, Zhao SK, Xiao X, Yu GT (2009) Wear behavior of Al2O3/Ti(C, N)/SiC new ceramic tool material when machining tool steel and cast iron. J Mater Process Technol 209:4633–4637. https://doi.org/10.1016/j.jmatprotec.2008.10.017

Vlasova M, Kakazey M, Hernandez AC, Aguilar PAM, Tapia RG, Mel’nikov IV, Petrovsky VN (2019) Surface changes in Al2O3-base composite ceramics under action of laser treatment. Ceram Int 45:5454–5466. https://doi.org/10.1016/j.ceramint.2018.11.249

Li CG, Yu SZ, Zhang YF, Zhang PL, Yan H, Lu QH, Li WG, Wang Y (2013) Microstructure evolution of laser remelted Al2O3-13wt.%TiO2 coatings. J Alloy Compd 576:187–194. https://doi.org/10.1016/j.jallcom.2013.04.100

Li ZL, Wei MM, Xiao K, Bai ZH, Xue W, Dong CF, Wei D, Li XG (2019) Microhardness and wear resistance of Al2O3-TiB2-TiC ceramic coatings on carbon steel fabricated by laser cladding. Ceram Int 45:115–121. https://doi.org/10.1016/j.ceramint.2018.09.140

Li CG, Zeng M, Liu CM, Wang FF, Guo YJ, Wang JQ, Yang Y, Li WG, Wang Y (2020) Microstructure and tribological behavior of laser cladding TiAlSi composite coatings reinforced by alumina–titania ceramics on Ti–6Al–4 V alloys. Mater Chem Phys 240:122271. https://doi.org/10.1016/j.matchemphys.2019.122271

Yue TM, Huang KJ, Man HC (2007) In situ laser cladding of Al2O3 bearing coatings on aluminum alloy 7075 for improvement of wear resistance. Surf Eng 23:142–146. https://doi.org/10.1179/174329407X169449

Wang WZ, Feng SS, Li ZM, Chen ZG, Zhao TY (2020) Microstructure and properties of micro-arcoxidation ceramic films on AerMet100 steel. J Mater Res Technol 9:6014–6027. https://doi.org/10.1016/j.jmrt.2020.04.005

He X, Song RG, Kong DJ (2019) Microstructure and corrosion behaviour of laser-cladding Al-Ni-TiC-CeO2composite coatings on S355 offshore steel. J Alloy Compd 770:771–783. https://doi.org/10.1016/j.jallcom.2018.08.058

Zhang PX, Pang YB, Yu MW (2019) Effects of WC particle types on the microstructures and properties of WC-reinforced Ni60 composite coatings produced by laser cladding. Metals-Basel 9:583. https://doi.org/10.3390/met9050583

Xiong LL, Zheng HZ, Yu P, Li GF, Chen Z, Zhang B (2015) Laser-clad YSZ@Ni (core–shell nanoparticle) composites coatings. Ceram Int 41:13850–13854. https://doi.org/10.1016/j.ceramint.2015.06.094

Uysal M, Karslioğlu R, Alp A, Akbulut H (2013) The preparation of core–shell Al2O3/Ni composite powders by electroless plating. Ceram Int 39:5485–5493. https://doi.org/10.1016/j.ceramint.2012.12.060

Hu GF, Yang Y, Qi Kang LuX, Li JD (2020) Investigation of the microstructure and properties of NiCrBSi coating obtained by laser cladding with different process parameters. Trans Indian Inst Metals 73:2623–2634. https://doi.org/10.1007/s12666-020-02065-w

Xiang K, Chai LJ, Wang YY, Wang H, Guo N, Ma YL, Murty KL (2020) Microstructural characteristics and hardness of CoNiTi medium-entropy alloy coating on pure Ti substrate prepared by pulsed laser cladding. J Alloy Compd 849:156704. https://doi.org/10.1016/j.jallcom.2020.156704

Sui XM, Lu J, Hu J, Zhang WP (2020) Effect of specific energy on microstructure and properties of laser cladded TiN/Ti3AlN-Ti3Al composite coating. Opt Laser Technol 131:106428. https://doi.org/10.1016/j.optlastec.2020.106428

Huang Y (2011) Characterization of dilution action in laser-induction hybrid cladding. Opt Laser Technol 43:965–973. https://doi.org/10.1016/j.optlastec.2010.12.005

Gao XS, Tian ZJ, Liu ZD, Shen LD (2012) Interface characteristics of Al2O3-13%TiO2 ceramic coatings prepared by laser cladding. Trans Nonferr Met Soc China 22:2498–2503. https://doi.org/10.1016/S1003-6326(11)61491-X

Xu P, Lin CX, Zhou CY, Yi XP (2014) Wear and corrosion resistance of laser cladding AISI 304 stainless steel/Al2O3 composite coatings. Surf Coat Technol 238:9–14. https://doi.org/10.1016/j.surfcoat.2013.10.028

Lin X, Yue TM, Yang HO, Huang WD (2007) Solidification behavior and the evolution of phase in laser rapid forming of graded Ti6Al4V-Rene88DT alloy. Metall Mater Trans A 38:127–137. https://doi.org/10.1007/s11661-006-9021-5

Fan L, Chen HY, Dong YH, Dong LH, Yin YS (2018) Wear and corrosion resistance of laser-cladded Fe-based composite coatings on AISI 4130 steel. Int J Min Met Mater 25:716–728. https://doi.org/10.1007/s12613-018-1619-2

Wang Q, Chen FQ, Zhang L, Li JD, Zhang JW (2020) Microstructure evolution and high temperature corrosion behavior of FeCrBSi coatings prepared by laser cladding. Ceram Int 46:17233–17242. https://doi.org/10.1016/j.ceramint.2020.04.010

Krämer M, Schilling M, Eifler R, Hering B, Reifenrath J, Besdo S, Windhagen H, Willbold E, Weizbauer A (2016) Corrosion behavior, biocompatibility and biomechanical stability of a prototype magnesium-based biodegradable intramedullary nailing system. Mater Sci Eng C Mater Biol Appl 59:129–135. https://doi.org/10.1016/j.msec.2015.10.006

Zou YC, Yan H, Hu Z, Ran QW (2020) Effect of (Pr + Ce) addition and T6 heat treatment on microhardness and corrosion of AlSi5Cu1Mg alloy. Mater Res Express 7:026526. https://doi.org/10.1088/2053-1591/ab6fa7

Macdonald JR (1992) Impedance spectroscopy. Ann Biomed Eng 20:289–305. https://doi.org/10.1007/BF02368532

Sato N (1971) A theory for breakdown of anodic oxide films on metals. Electrochim Acta 16:1683–1692. https://doi.org/10.1016/0013-4686(71)85079-X

Uhlig HH (1950) Adsorbed and reaction-produce films on metals. J Electrochem Soc 97:215C–220C. https://doi.org/10.1149/1.2777892

Liu SS, Chen HY, Zhao X, Fan L, Guo XM, Yin YS (2019) Corrosion behavior of Ni-based coating containing spherical tungsten carbides in hydrochloric acid solution. J Iron Steel Res Int 26:191–199. https://doi.org/10.1007/s42243-019-00240-y

Acknowledgements

This study was supported by the national natural science foundation of China (No. 51965040), and the Natural Science Foundation of Jiangxi Province (No. 20181BAB206026).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, PX., Yan, H. & Sun, YH. Microstructure, microhardness and corrosion resistance of laser cladding Al2O3@Ni composite coating on 304 stainless steel. J Mater Sci 56, 8209–8224 (2021). https://doi.org/10.1007/s10853-020-05741-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05741-w